Error reduction type seed weighing method and weighing machine

A weighing machine and seed technology are applied in the field of error reduction and formal seed weighing method and weighing machine, which can solve the problems of large size of the machine, unfavorable popularization and high manufacturing cost, and achieve high measurement speed and accuracy, which is conducive to popularization and popularization. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

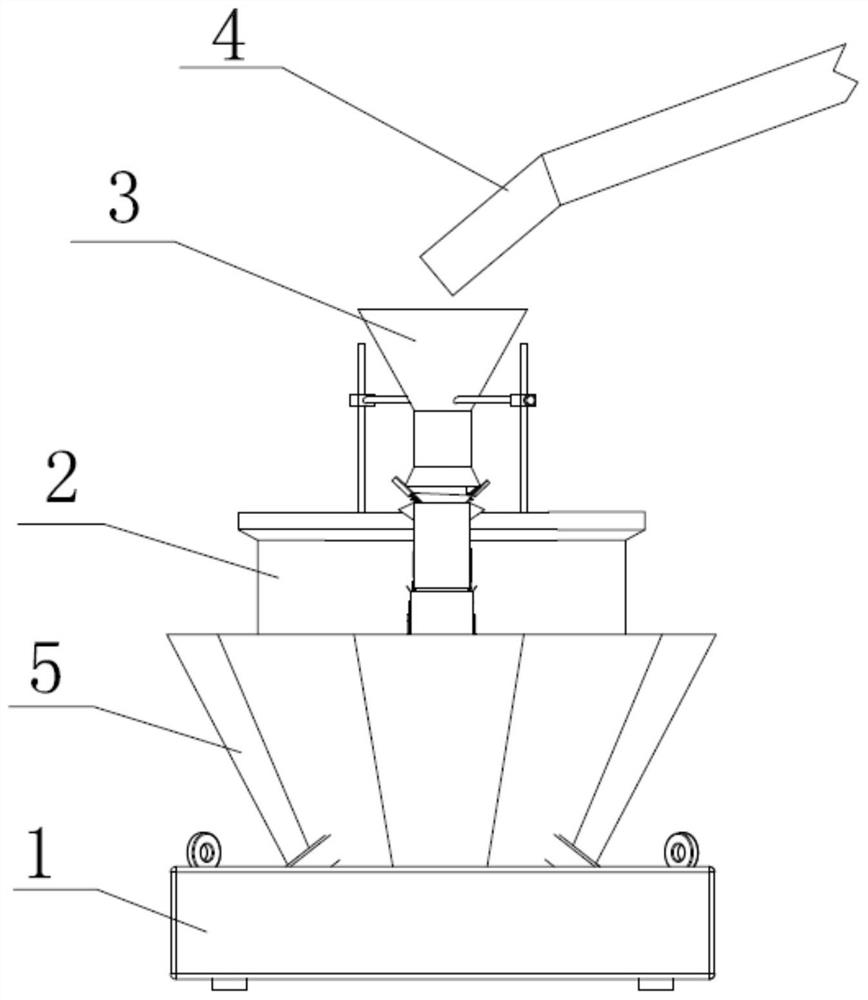

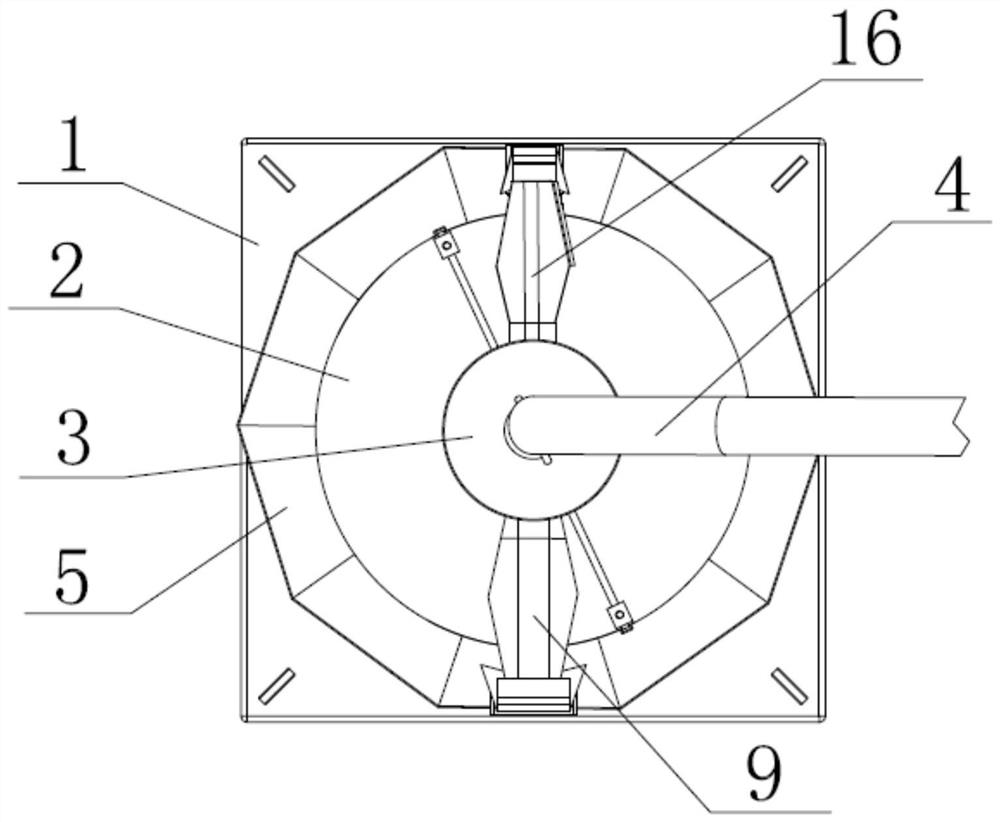

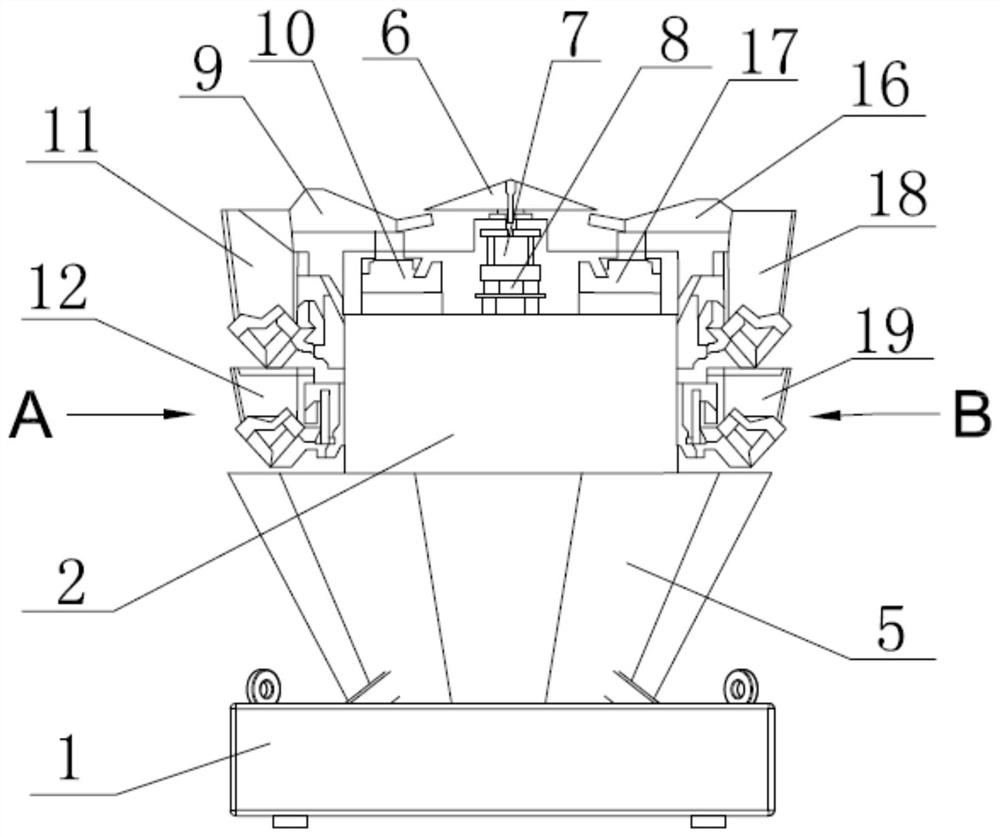

[0041] Such as Figure 1-Figure 3 As shown, a weighing machine includes a base 1, a mounting seat 2 is fixed on the base 1, a main vibration mechanism is provided at the center of the mounting seat 2, a main weighing mechanism is provided on one side of the main vibration mechanism, and a main weighing mechanism is provided on the other side. There is an auxiliary weighing mechanism for correcting the error of the main weighing mechanism. The upper part of the main vibrating mechanism is provided with a feeding tray 3 for feeding materials. Conical funnel shape, the outlet at the bottom is aligned with the main vibration mechanism, the bottom of the mounting seat 2 is provided with a chute plate 5 for carrying the main weighing mechanism and auxiliary weighing mechanism blanking, the chute plate 5 is composed of several A disc-shaped structure surrounded by inclined sloping plates.

[0042] The seeds fall onto the main vibrating mechanism through the feeding tray 3, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com