Gas constant temperature device for detecting sealing performance of parts

A technology of sealing detection and constant temperature device, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of internal pressure change, interference detection effect, high cost, etc., to reduce the test pressure difference error and change the volume flexibly , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

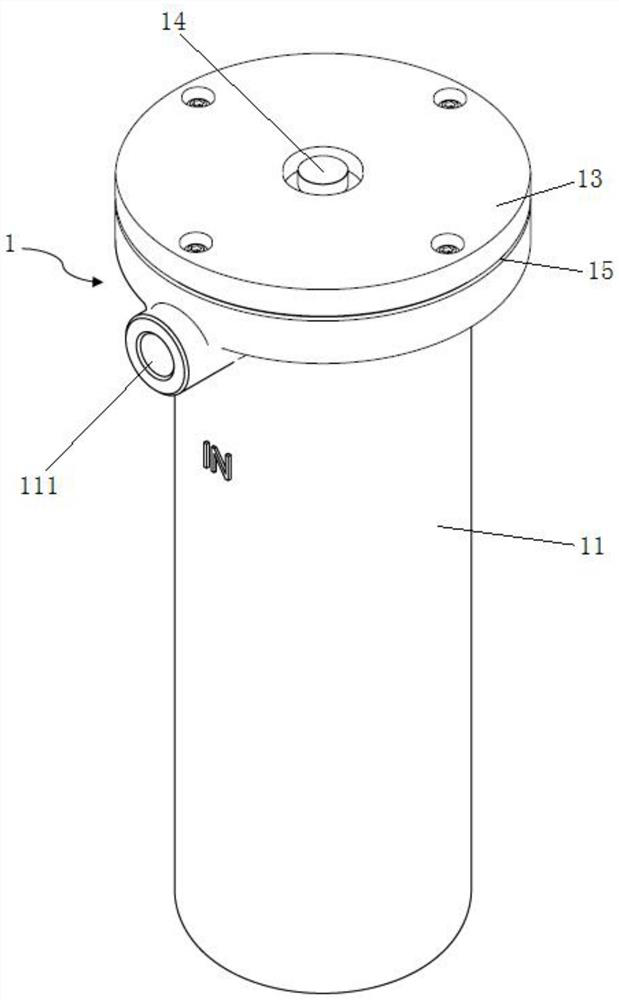

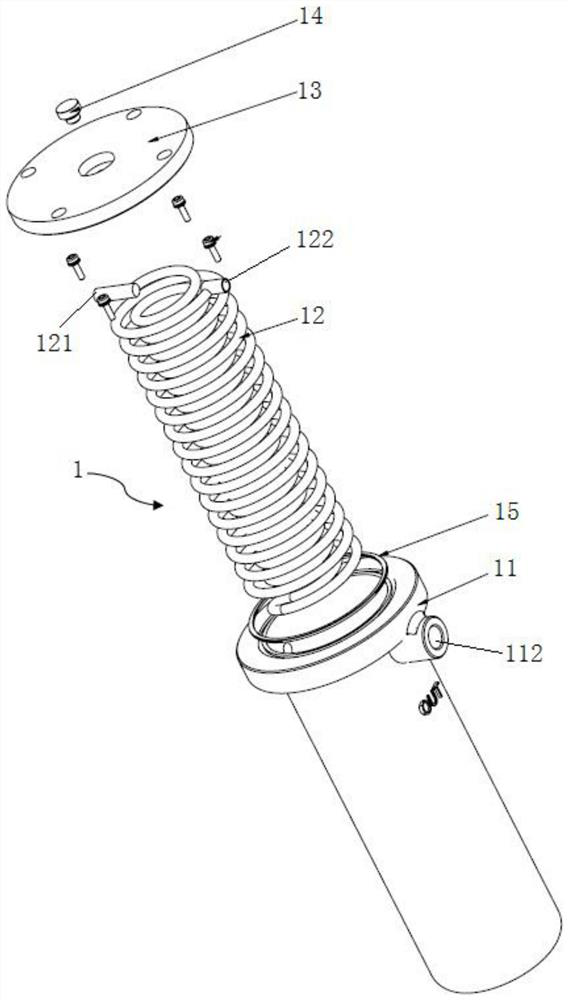

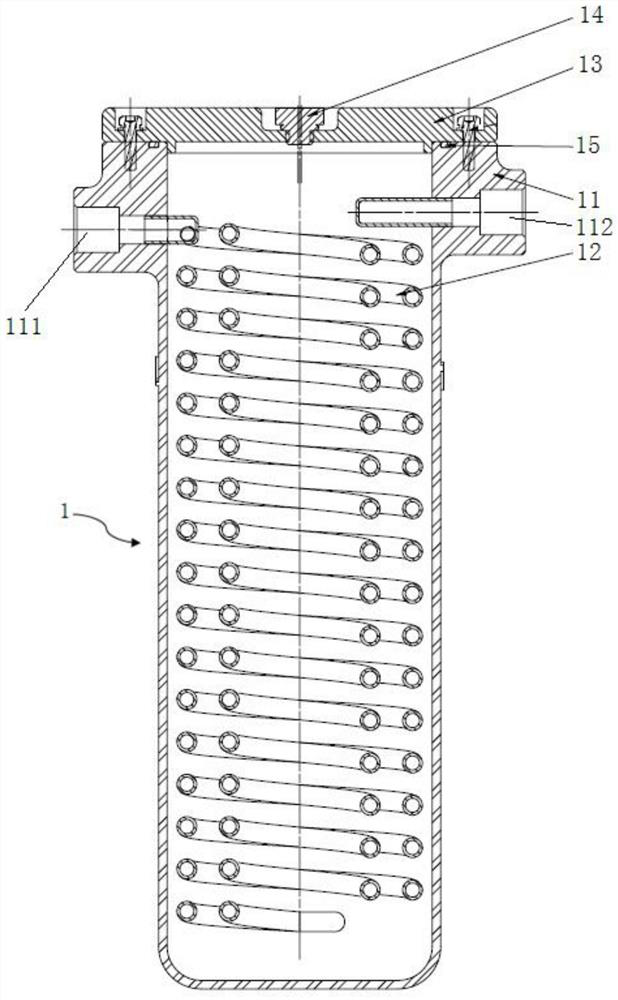

[0027] see figure 1 , figure 2 , image 3 , which is a gas thermostat for detecting the airtightness of parts and components provided by the embodiment of the present invention, such as figure 1 , figure 2 , image 3 As shown, the device may include:

[0028] The heat exchange mechanism 1 is configured to be arranged between the gas source and the component sealing detection equipment, and adjust the temperature of the gas supplied by the gas source to a target temperature before supplying it to the component sealing detection equipment.

[0029] The heat exchange mechanism provided in the embodiment of the present application is arranged between the gas source and the component seal detection equipment, which can adjust the temperature of the gas entering the component seal detection equipment, so as to reduce the test pressure difference error. The mechanism can be any mechanism that can realize gas heat exchange. For example, the embodiment of the present application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com