Damping rack and detection equipment adopting same

A technology of bench and shock absorber, which is applied in the field of shock absorbing bench and testing equipment using the shock absorbing bench, to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

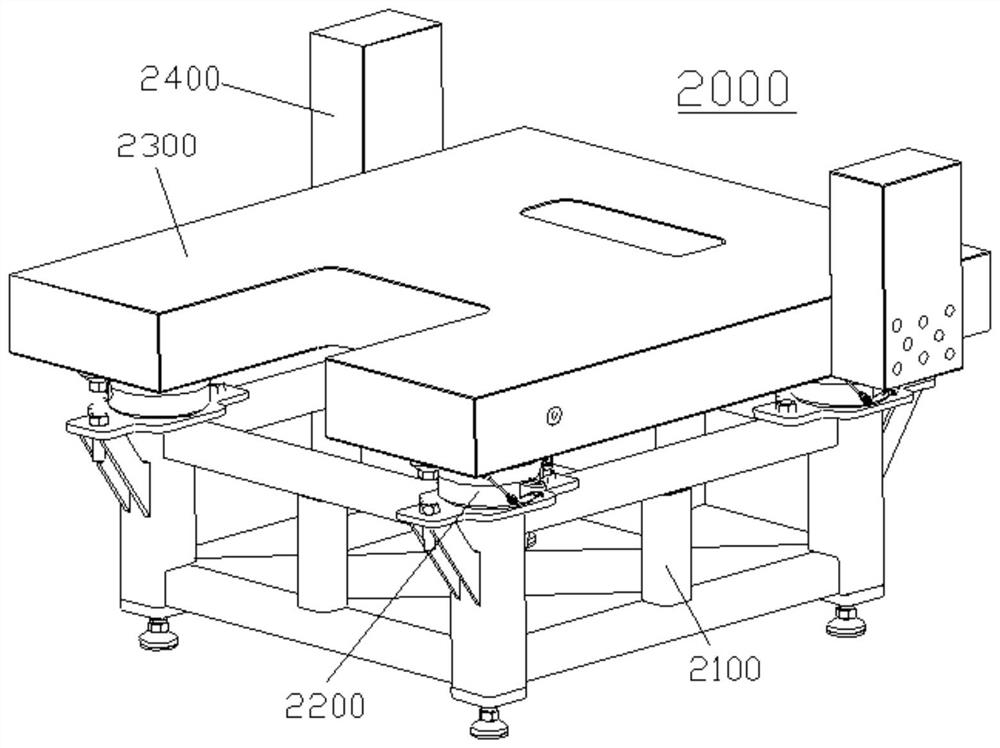

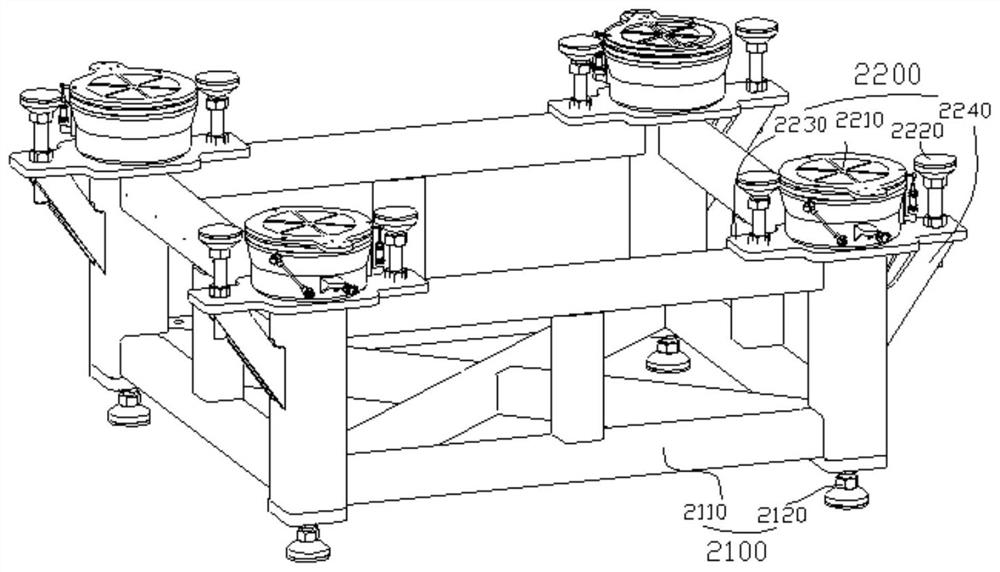

[0037] A shock-absorbing stand, see figure 1 with figure 2 , The shock-absorbing bench 2000 includes a lower steel frame 2100 , a shock-absorbing support assembly 2200 , a bench carrying platform 2300 and a detection carrying bottom column 2400 . The lower steel frame 2100, the shock-absorbing support assembly 2200 and the platform carrying platform 2300 are arranged in this way from bottom to top.

[0038] The lower steel frame 2100 is built into a rectangular frame with stainless steel or aluminum alloy profiles, and two supporting beams are arranged diagonally in the middle. Specifically, the lower steel frame 2100 includes a steel frame body 2110 made of modular profiles and platform feet 2120 are set at the bottom of the four corners of the steel frame body 2110. The platform feet 2120 include foot pads and anchor bolts. To anti-slip, support, shock absorption and height adjustment. The platform feet 2120 and the shock-absorbing support assembly 2200 form a shock-abso...

Embodiment 2

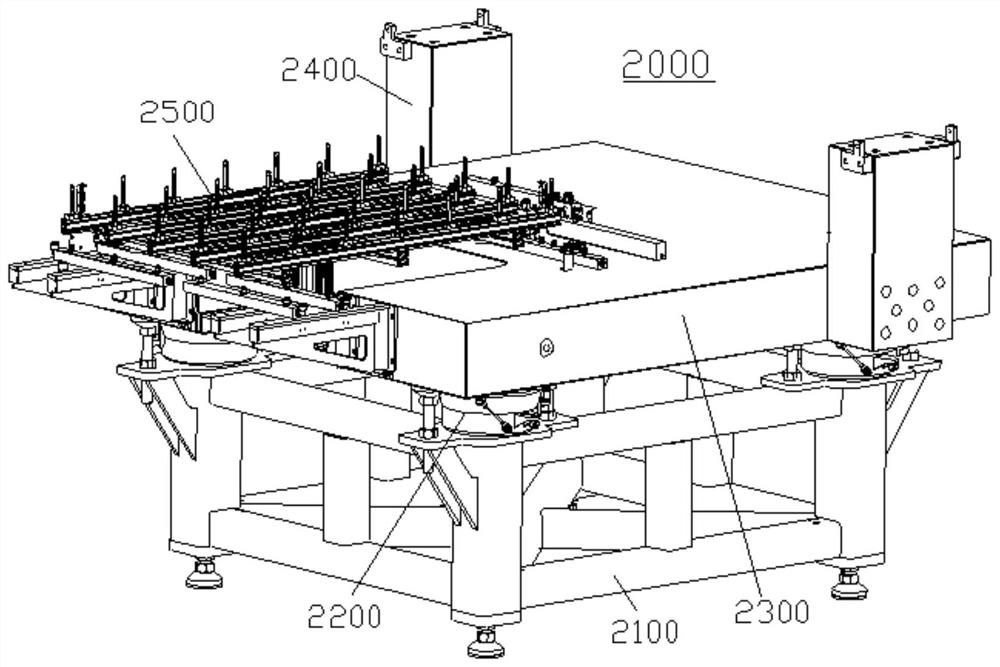

[0044] Further, see image 3 with Figure 4 , in order to realize the auxiliary support and lifting adjustment of the platform to be tested, the shock absorbing stand 2000 also includes a jacking module 2500, and the jacking module 2500 is set at the jacking gap opened on the shock absorbing bottom plate 2230 for Receive and lift the DUT.

[0045] Correspondingly, a lifting gap needs to be provided on the supporting platform 2300 of the stand.

[0046] Specifically, see Figure 4 , the jacking module 2500 includes a jacking base 2510, a synchronizer 2520, a jacking motor 2530, a jacking upper frame 2540, and a thimble set 2550. The rectangular jacking base 2510 composed of profiles is fixed to the lower steel frame 2100, and the synchronizer 2520 is set On the four corners of the lifting base 2510 , the lifting motor 2530 is arranged in the middle of the lifting base 2510 , and the lifting motor 2530 is arranged flush with the top surface of the synchronizer 2520 . The jac...

Embodiment 3

[0051] A kind of detection equipment that adopts aforementioned shock absorbing bench, see Figure 5 , the detection equipment includes a functional outer box 1000, a shock absorbing stand 2000, a platform module 3000, a transfer module 4000 and an optical detection device 5000, wherein the shock absorbing stand 2000, the platform module 3000, and the transfer module 4000 It is non-rigidly connected or spaced from the optical detection device 5000 and arranged in the functional outer box 1000 .

[0052] The platform module 3000 is arranged on the shock-absorbing stand 2000, and the platform module 3000 is used for air bearing and positioning of the test piece, and the floating flatness of the platform module 3000 is ±20 μm. The optical detection device 5000 is arranged above the platform module 3000 for detection of the DUT. The transfer module 4000 is arranged under the optical detection device 5000 , and is used to transfer the DUT between the material inlet and outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com