A non-enzymatic electrochemical sensor for the simultaneous detection of glucose and uric acid

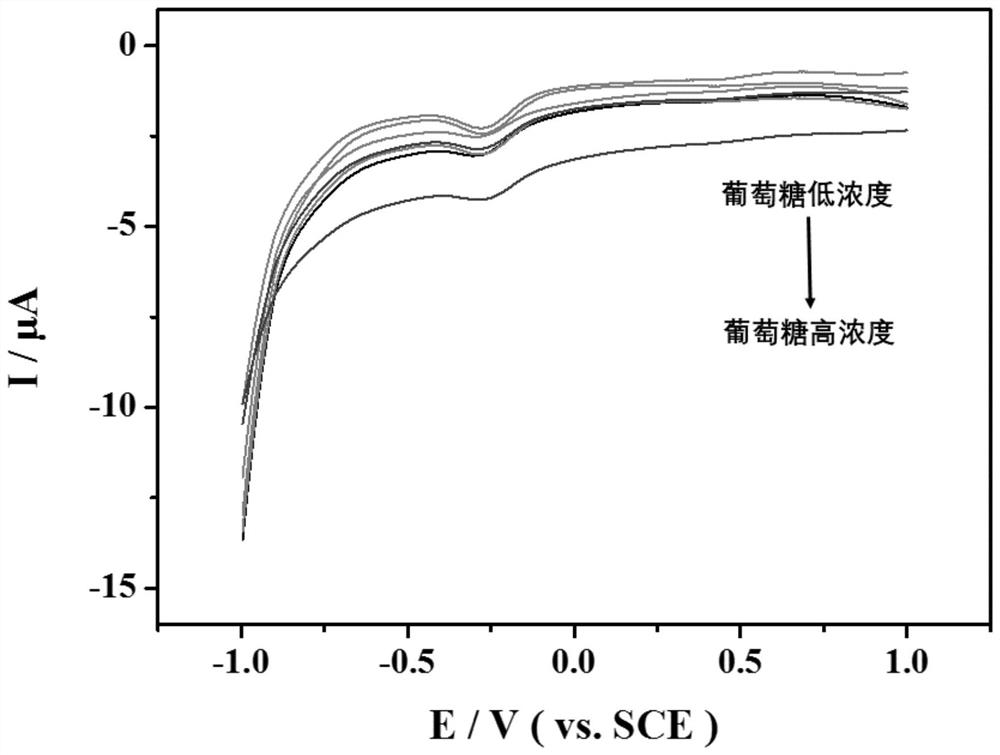

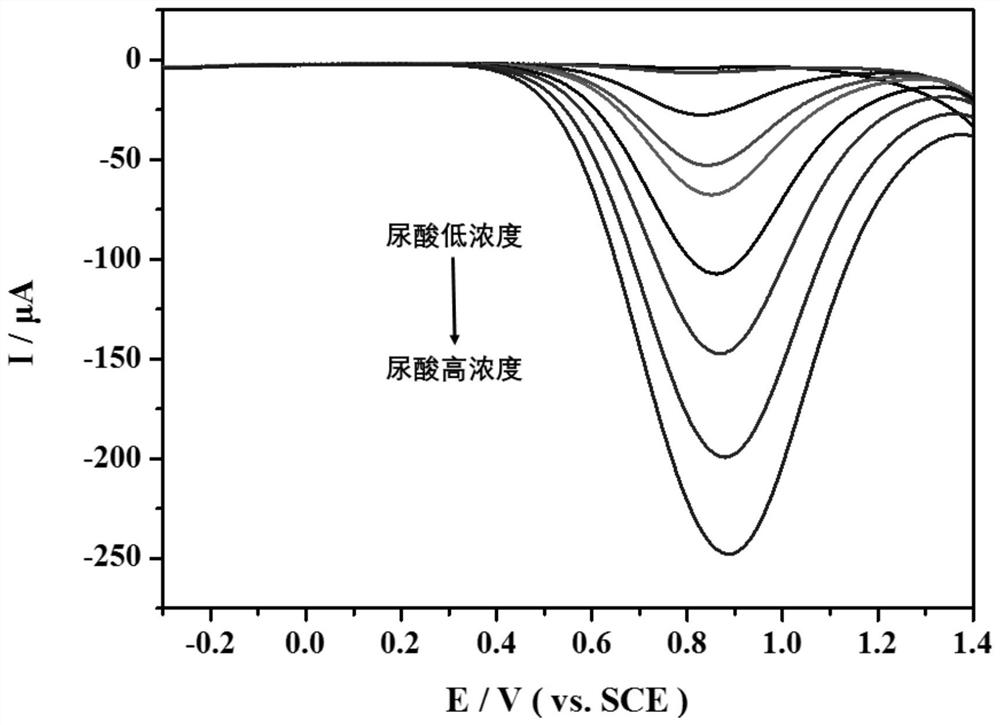

A sensor and electrochemical technology, applied in the field of non-enzymatic electrochemical sensors, can solve the problems of simultaneous detection of glucose and other problems, achieve excellent catalytic ability, wide application prospects, and overcome the effect of easy deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

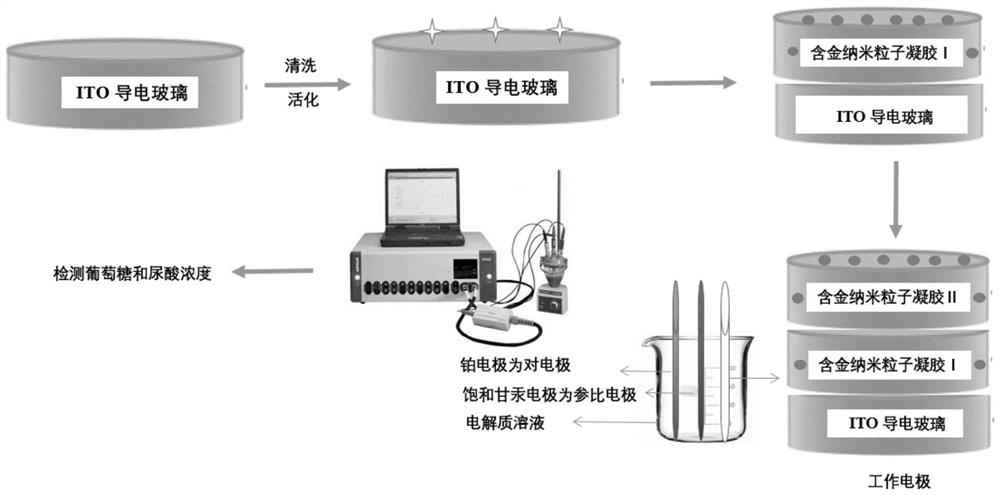

Method used

Image

Examples

Embodiment 1

[0053] (1) Ultrasonic the ITO conductive glass with a cleaning agent for 30 minutes, then clean it with distilled water, then use acetone, ethanol, and distilled water to sonicate for 5 minutes, then soak the ITO conductive glass in sodium hydroxide solution for 8 hours, and wash it with deionized water Blow dry after rinsing;

[0054] (2) 2.4×10 -2 mol / L sodium citrate solution and 2.4×10 -2 Take 0.5mL of each mol / L tetrachloroauric acid solution, set the volume to 50mL, slowly add 0.1mol / L sodium borohydride solution dropwise under magnetic stirring, stop the dropwise addition when the solution turns from colorless to pink, and prepare A gold nanoparticle solution with an average particle diameter of 158nm was obtained;

[0055] (3) Get the gold nanoparticle solution in step (2), 30% stock gel solution, 1.0mol / L 3-hydroxyaminomethane hydrochloric acid buffer (pH=8.8), 5% sodium lauryl sulfate solution, 5% ammonium persulfate solution and tetramethylethylenediamine solutio...

Embodiment 2

[0062] The preparation method of the sensor based on gold nanoparticle gradient polyacrylamide gel modification described in this embodiment is different from Example 1 in that: in step (3), gold nanoparticle solution, 30% stock gel solution , 2.0mol / L 3-hydroxyaminomethane hydrochloric acid buffer solution (pH=8.8), 15% sodium lauryl sulfate solution, 15% ammonium persulfate solution and tetramethylethylenediamine solution according to volume ratio 4.6: 2.7 : 2.5: 0.1: 0.1: 0.006 mixed to prepare gel solution I; in step (5), gold nanoparticle solution, 30% stock gel solution, 1.5mol / L 3-hydroxyaminomethane hydrochloric acid buffer (pH =6.8), 15% sodium lauryl sulfate solution, 15% ammonium persulfate solution and tetramethylethylenediamine solution are mixed according to volume ratio 4.1: 1: 0.75: 0.06: 0.06: 0.006 to obtain a gel solution Ⅱ; The sensor based on gradient polyacrylamide gel modification of gold nanoparticles was prepared.

[0063] The 30% reserve gel solution...

Embodiment 3

[0065] The preparation method of the sensor based on gold nanoparticle gradient polyacrylamide gel modification described in this embodiment is different from Example 1 in that: in step (3), gold nanoparticle solution, 30% stock gel solution , 1.5mol / L 3-hydroxyaminomethane hydrochloric acid buffer solution (pH=8.8), 10% sodium lauryl sulfate solution, 10% ammonium persulfate solution and tetramethylethylenediamine solution according to volume ratio 2.3:5 : 2.5: 0.1: 0.1: 0.004 mixed to prepare gel solution I; in step (5), gold nanoparticle solution, 30% stock gel solution, 1mol / L 3-hydroxyaminomethane hydrochloric acid buffer (pH = 6.8), 10% sodium lauryl sulfate solution, 10% ammonium persulfate solution and tetramethylethylenediamine solution are mixed according to volume ratio 1.4: 0.33: 0.25: 0.02: 0.02: 0.02 to obtain gel solution II ; A gold nanoparticle-based gradient polyacrylamide gel-modified sensor was prepared.

[0066] The 30% reserve gel solution was purchased ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com