Scrap suction type nut tapping device and using method thereof

A nut and vacuum cleaner technology, which is applied in the field of chip-absorbing nut tapping devices, can solve the problems of metal chips, nut positioning influence, influence on tapping accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

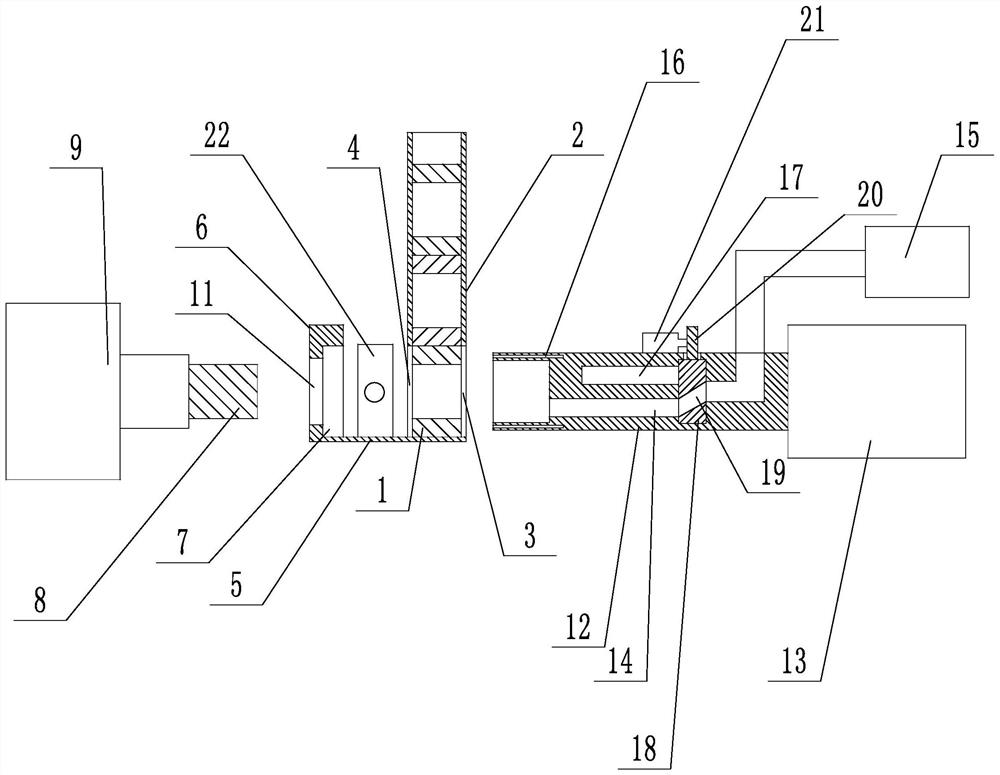

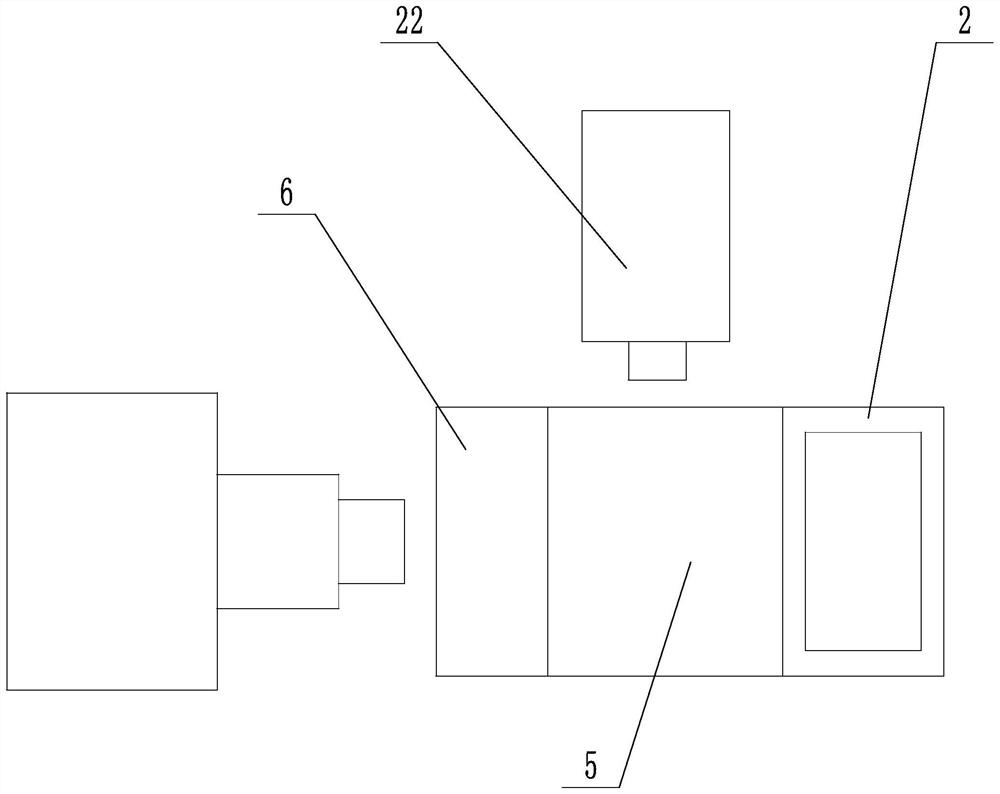

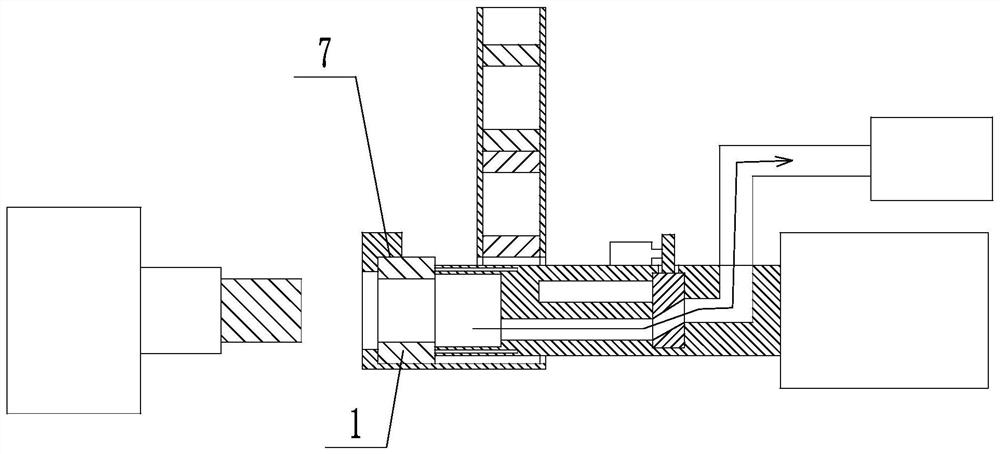

[0018] see Figure 1 to Figure 4 , a chip suction type nut tapping device, including a drop tube 2 for stacking nuts 1, a through hole 3 located on one side of the lower end of the drop tube 2, a discharge port 4 located on the other side of the lower end of the drop tube 2, and a The slide plate 5 for the nut 1 to slide on the lower end side of the drop tube 2, the support seat 6 fixedly connected to the slide plate 5, and the limit groove 7 located on the support seat 6 are used to push the nut 1 out of the discharge port through the through hole 3 4. Then press the nut 1 into the clamping mechanism in the limit groove 7, and the tapping mechanism located on the side of the support seat 6 away from the drop tube 2;

[0019] The tapping mechanism includes a screw tap 8, a motor 9 for rotating the screw tap 8, and a drive cylinder for driving the motor 9 to move to the support seat 6;

[0020] The bottom of the limiting groove 7 is provided with a second via hole 11 for avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com