Diesel engine oil complexing agent and preparation method thereof

A compounding agent and diesel engine technology, applied in the field of lubricating oil, can solve the problems of uneven technical level, lack of data support and practical verification, etc., and achieve the effect of good energy saving, control of deposit formation and fuel saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

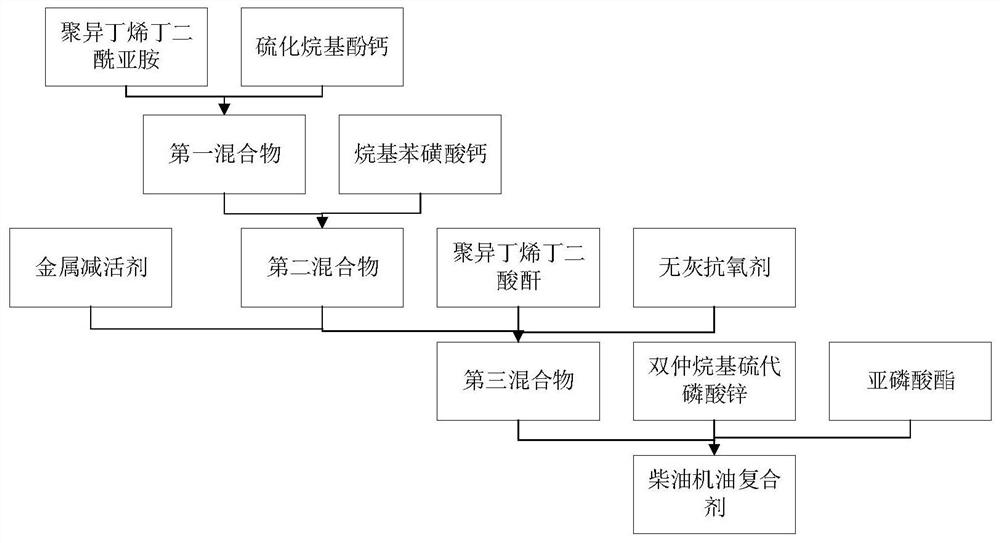

[0027] Please refer to figure 1 , the embodiment of the present invention provides a kind of preparation method of diesel engine oil compounding agent, comprises the following steps:

[0028] Step S1: Add 50%-60% polyisobutylene succinimide and 9%-15% sulfurized calcium alkylphenate to the container in order by mass percentage, heat up to 70-80°C while stirring, and stir for 60 minutes. The first mixture is obtained; the sulfurized alkyl phenate calcium is selected from a high alkali value sulfurized alkyl phenate calcium with a base value of 250-280mgKOH / g or a low base value sulfurized alkyl phenate calcium with a base value of 150-170mgKOH / g; The diimide is selected from high molecular weight polyisobutylene succinimide with a molecular weight of 2000-3000 or boronated polyisobutylene succinimide with a molecular weight of 1500-2000;

[0029] Step S2: Add 10%-25% calcium alkylbenzenesulfonate to the first mixture by mass percentage, keep stirring at 70-80°C for 60 minutes ...

Embodiment 1

[0034] In terms of mass percentage, add 50% of high molecular weight polyisobutylene succinimide with a molecular weight of 2000-3000 and 9% of low-basic value sulfurized alkylphenate calcium with a basic value of 150-170 mgKOH / g to the container, stirring While raising the temperature to 70°C, stir for 60 minutes to obtain the first mixture; add 24% calcium alkylbenzenesulfonate with a base value of 20-30mgKOH / g to the first mixture, and keep stirring at 70°C 60min, the second mixture was obtained; in the second mixture, 0.5% polyisobutylene succinic anhydride, 8.0% nonyl diphenylamine and 0.7% benzotriazole were added successively, and stirred for 60min to obtain the third mixture; In terms of percentages, 7% bis-n-propanol zinc thiophosphate and 0.8% phosphite were added to the third mixture, and blended for 60 minutes to obtain the diesel engine oil compounding agent.

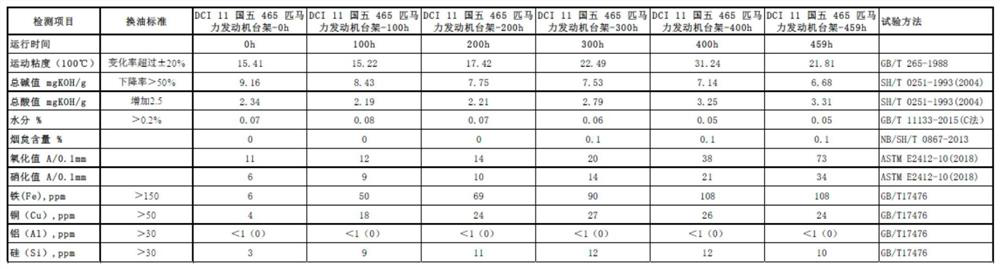

[0035] The diesel engine oil compound prepared in Example 1 was sampled and analyzed. During the analysi...

Embodiment 2

[0043]In terms of mass percentage, add 58% of high molecular weight polyisobutylene succinimide with a molecular weight of 2000-3000 and 10% of low-basic value sulfurized alkylphenate calcium with a basic value of 150-170mgKOH / g in the container, stirring While raising the temperature to 75°C, stir for 60 minutes to obtain the first mixture; add 15% calcium alkylbenzenesulfonate with a base value of 20-30 mgKOH / g to the first mixture, and keep stirring at 75°C 60min to obtain the second mixture; by mass percentage, sequentially add 0.8% polyisobutylene succinic anhydride, 5.2% nonyl diphenylamine and 0.4% thiadiazole to the second mixture, stir for 60min to obtain the third mixture; In percentage terms, 10% bis-n-propanol zinc thiophosphate and 0.6% phosphite were added to the third mixture, and blended for 60 minutes to obtain the diesel engine oil compounding agent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap