One-step production process of water electret meltblown cloth

A technology of melt-blown cloth and electret, which is applied in the direction of non-woven fabrics, dry gas arrangement, lighting and heating equipment, etc. It can solve the problems of water-electret melt-blown cloth not easy to dry, high production cost, and fast static decay. , to prolong electrostatic adsorption time, reduce production cost and improve filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

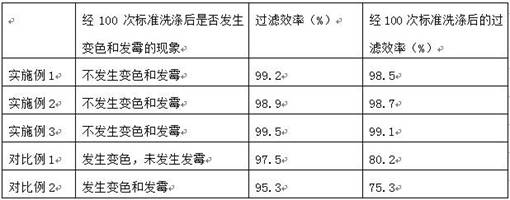

Examples

Embodiment 1

[0031] The particle size of the zirconium dioxide powder is 20 μm.

[0035] The particle size of the oxidized polyethylene wax is 10 μm.

[0036] The particle size of the volcanic rock powder is 150 μm.

Embodiment 2

[0045] The particle size of the zirconium dioxide powder is 25 μm.

[0049] The particle size of the oxidized polyethylene wax is 30 μm.

[0050] The particle size of the volcanic rock powder is 160 μm.

Embodiment 3

[0059] The particle size of the zirconium dioxide powder is 30 μm.

[0063] The particle size of the oxidized polyethylene wax is 40 μm.

[0064] The particle size of the volcanic rock powder is 180 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com