One-step production process of water electret melt-blown cloth

A production process, the technology of melt-blown cloth, which is applied in the field of one-step production process of water-electret melt-blown cloth, can solve the problems that water-electret melt-blown cloth is not easy to dry, high production cost, and fast static decay, etc. Prolong electrostatic adsorption time, reduce production cost and improve filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

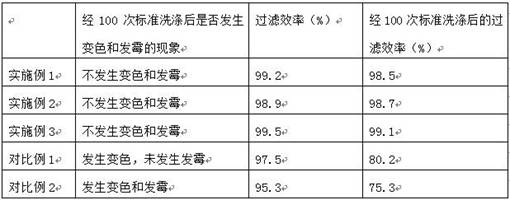

Examples

Embodiment 1

[0029] A raw material for water electret meltblown cloth, in parts by weight, comprising: 120 parts of polypropylene resin, 3 parts of zirconia powder, 1 part of light calcium carbonate, 0.5 part of polyvinylamine, 5 parts of anionic polyacrylamide , 3 parts of oxidized polyethylene wax, 2 parts of volcanic stone powder.

[0030] Among them, according to the GB / T 3682.1-2018 standard, the heating temperature is set to 230°C, and the rated load is set to 2.16kg to normally detect the melt flow rate of the sample to be tested. The measured melt flow rate of the polypropylene resin is 1500g / 10min.

[0031] The particle size of the zirconium dioxide powder is 20 μm.

[0032] The particle size of the light calcium carbonate is 100nm.

[0033] The polyvinylamine is a white powder with a content of 75% and a particle size of 50 μm.

[0034] The anionic polyacrylamide has a solid content ≥ 88%, a molecular weight of 8-20 million, a degree of hydrolysis of 10-80%, and a particle si...

Embodiment 2

[0043] A raw material for water electret melt-blown cloth, in parts by weight, comprising: 125 parts of polypropylene resin, 4 parts of zirconia powder, 1.5 parts of light calcium carbonate, 0.7 part of polyvinylamine, 6 parts of anionic polyacrylamide , 4 parts of oxidized polyethylene wax, 3 parts of volcanic stone powder.

[0044]Among them, according to the GB / T 3682.1-2018 standard, the heating temperature is set to 230°C, and the rated load is set to 2.16kg to normally detect the melt flow rate of the sample to be tested. The measured melt flow rate of the polypropylene resin is 1500g / 10min.

[0045] The particle size of the zirconium dioxide powder is 25 μm.

[0046] The particle size of the light calcium carbonate is 700nm.

[0047] The polyvinylamine is a white powder with a content of 78% and a particle size of 70 μm.

[0048] The anionic polyacrylamide has a solid content ≥ 88%, a molecular weight of 8-20 million, a degree of hydrolysis of 10-80%, and a particle...

Embodiment 3

[0057] A raw material for water electret meltblown cloth, in parts by weight, including: 130 parts of polypropylene resin, 5 parts of zirconia powder, 2 parts of light calcium carbonate, 1 part of polyvinylamine, 7 parts of anionic polyacrylamide , 5 parts of oxidized polyethylene wax, 4 parts of volcanic stone powder.

[0058] Among them, according to the GB / T 3682.1-2018 standard, the heating temperature is set to 230°C, and the rated load is set to 2.16kg to normally detect the melt flow rate of the sample to be tested. The measured melt flow rate of the polypropylene resin is 1500g / 10min.

[0059] The particle size of the zirconia powder is 30 μm.

[0060] The particle size of the light calcium carbonate is 1000nm.

[0061] The polyvinylamine is a white powder with a content of 81% and a particle size of 90 μm.

[0062] The anionic polyacrylamide has a solid content ≥ 88%, a molecular weight of 8-20 million, a degree of hydrolysis of 10-80%, and a particle size of 60-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com