Advanced grouting method

An advanced grouting and grouting technology, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., to reduce the probability of subsidence and facilitate excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

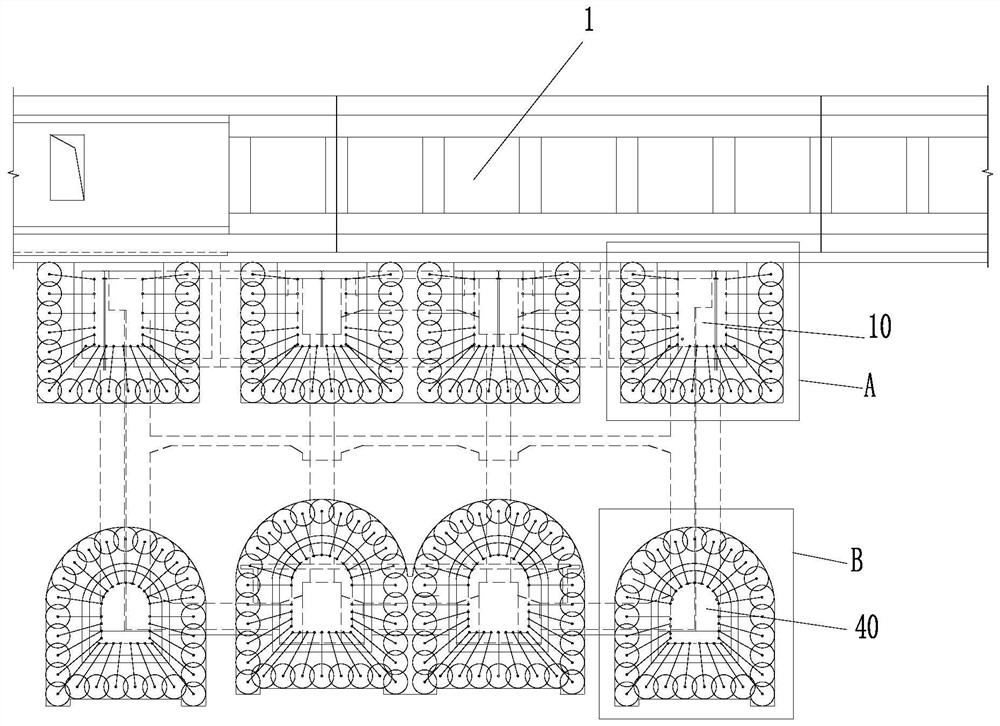

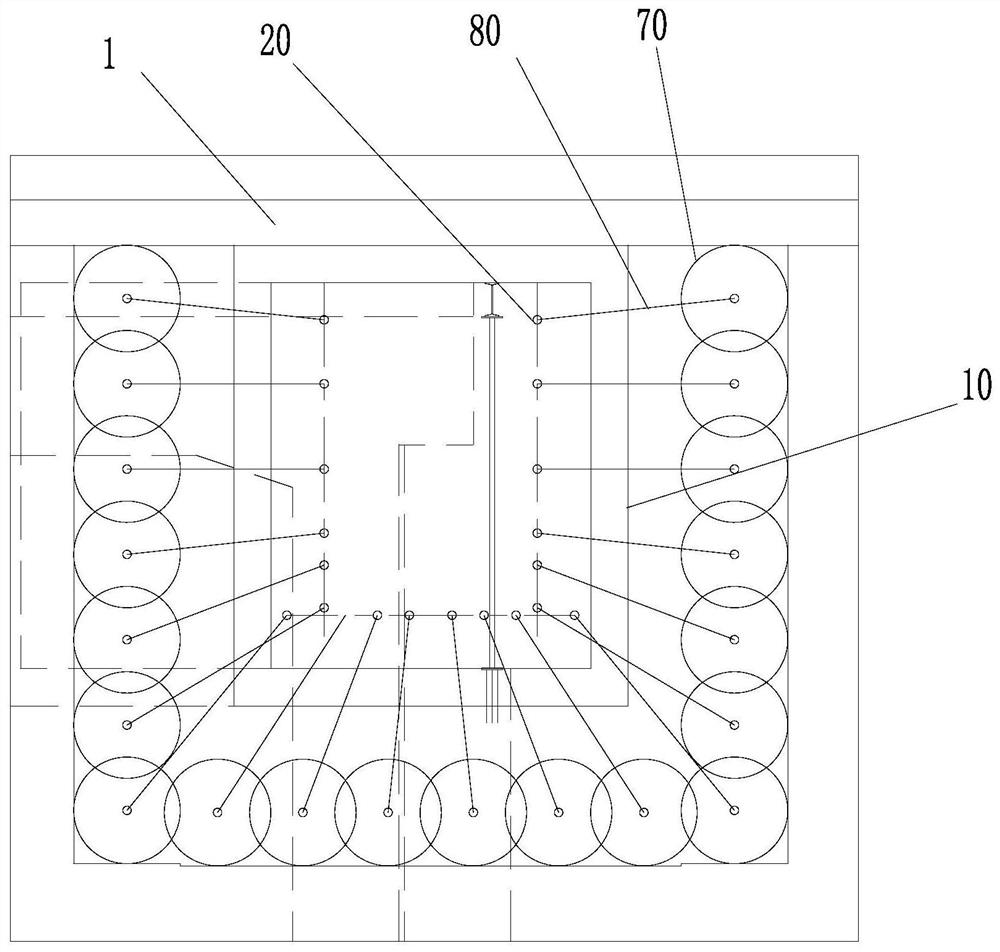

[0030] like Figure 1 to Figure 3 As shown, there is a first pilot tunnel 10 below the existing building 1, and the advanced grouting method of the present embodiment includes:

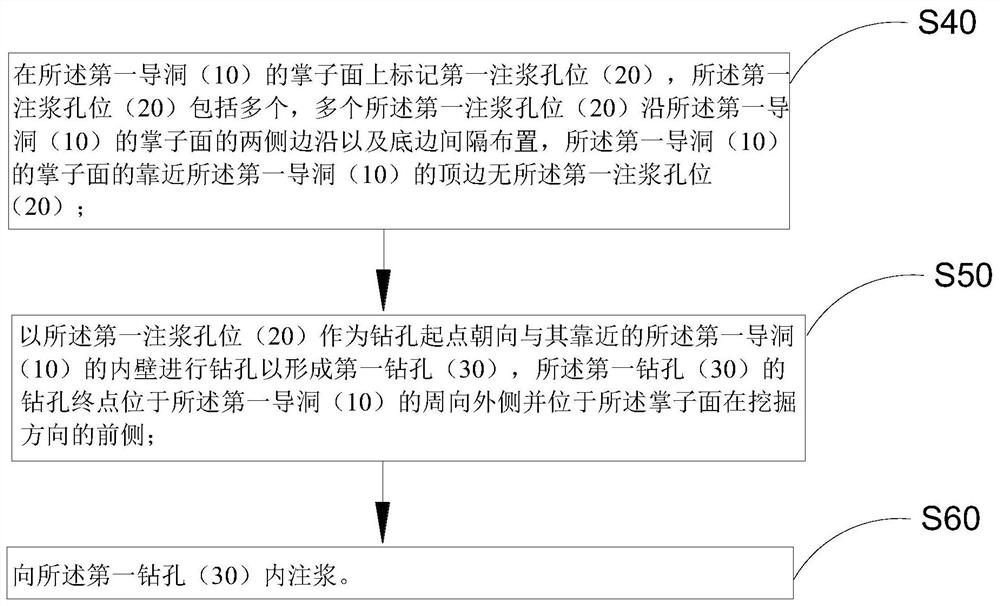

[0031] Step S40: mark the first grouting hole position 20 on the palm surface of the first guide hole 10, the first grouting hole position 20 includes a plurality of first grouting hole positions 20 along the first guide hole 10 The two side edges and the bottom edge of the tunnel surface are arranged at intervals, and there is no first grouting hole position 20 on the tunnel surface of the first pilot hole 10 near the top edge of the first pilot tunnel 10;

[0032] Step S50: take the first grouting hole 20 as the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com