Ultra-shallow-buried shed cover underground excavation station construction method

A construction method and shed cover technology, applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve problems such as poor support effect, achieve the effects of reducing the distance of settlement, improving support effect, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following is attached Figure 1-8 The application is described in further detail.

[0053] The embodiment of the present application discloses a construction method for an ultra-shallow buried cover excavation station.

[0054] The construction method of ultra-shallow buried cover excavation station includes the following specific construction steps:

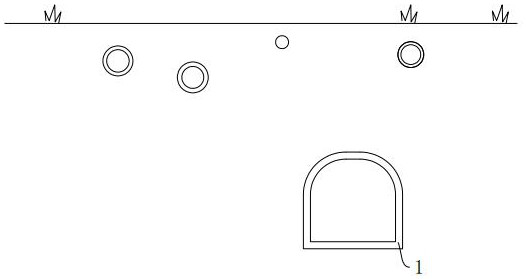

[0055] refer to figure 1 , S1. Preliminary measurement preparations are carried out, the depth and position of the pipeline are calculated, the shaft construction is carried out and the transverse passage is dug.

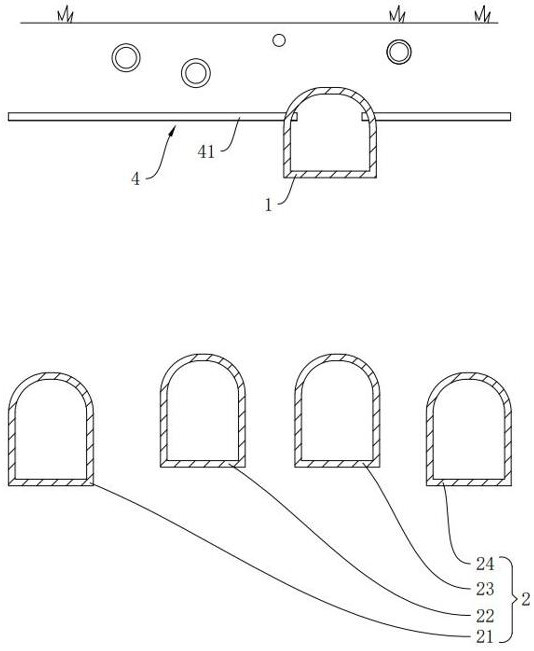

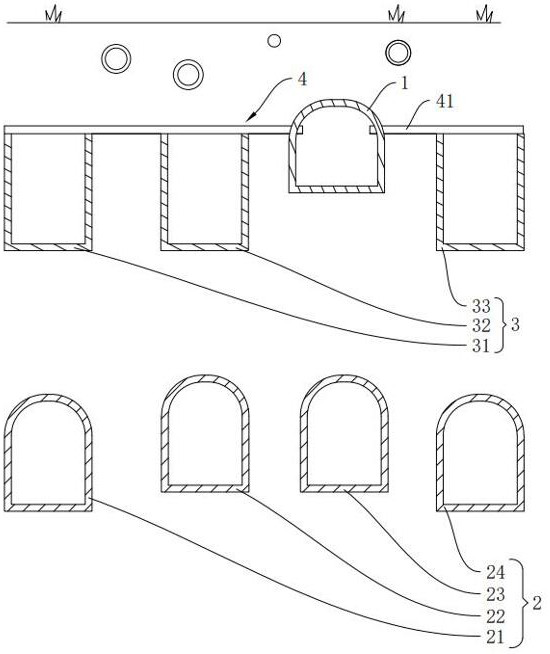

[0056] combine figure 2 , S2. Use the step method to dig out the leading pilot tunnel 1. The length of the steps used is 2-5m. After the top of the leading pilot tunnel 1 is closed to form a raised ring, timely carry out grouting reinforcement, and if necessary, carry out secondary grouting.

[0057] Then adopt the hydrostatic jacking method to insert the supporting steel pipe 41 perpendicular to the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com