Corrugated flange structure for circumferential connection of corrugated steel pipes and manufacturing method of corrugated flange structure

A technology of corrugated steel pipes and manufacturing methods, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, hoses, etc., can solve problems such as the inability to use corrugated flanges, high welding costs, and difficult control of deformation, and achieve improved Welding quality and welding efficiency, assembly and welding process are easy to implement, and the effect of improving the ability to withstand shock loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

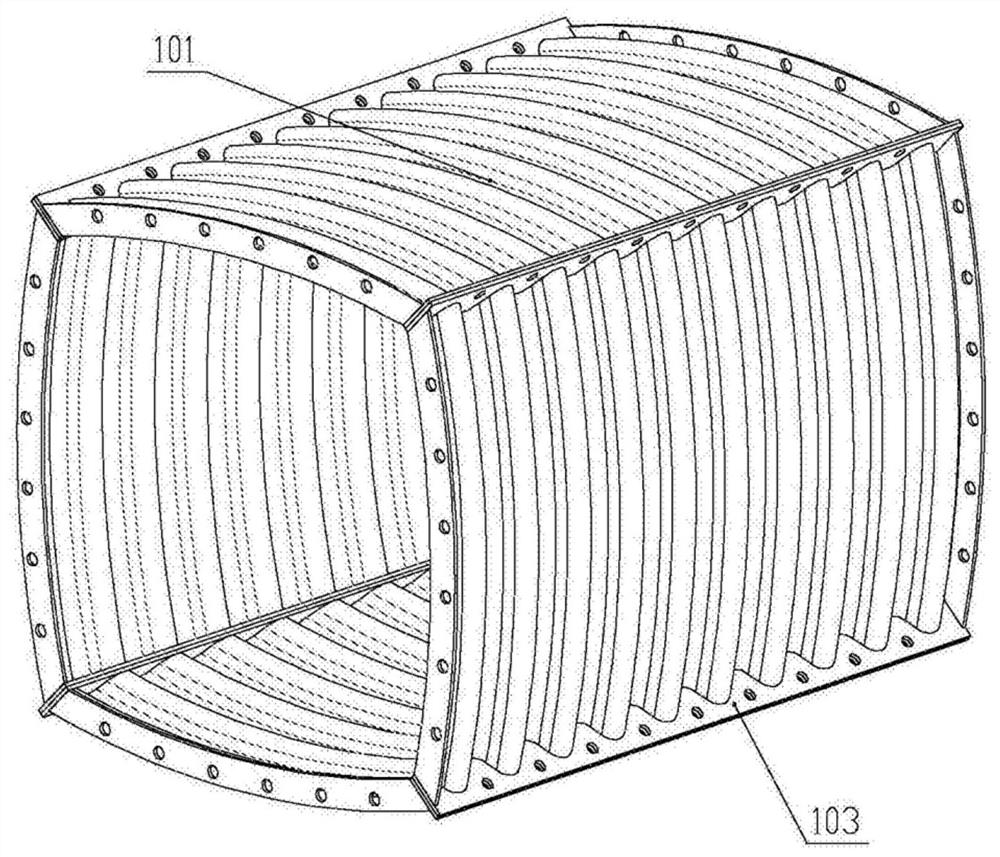

[0039] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0040] In this embodiment, the method for manufacturing the circumferential connecting flange of the corrugated steel pipe includes the following steps:

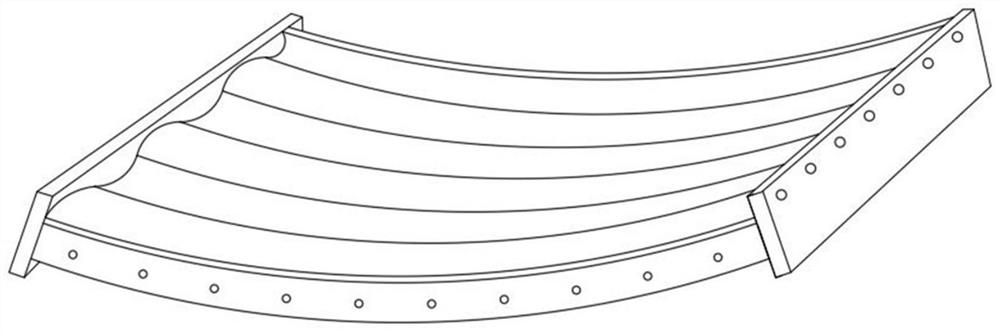

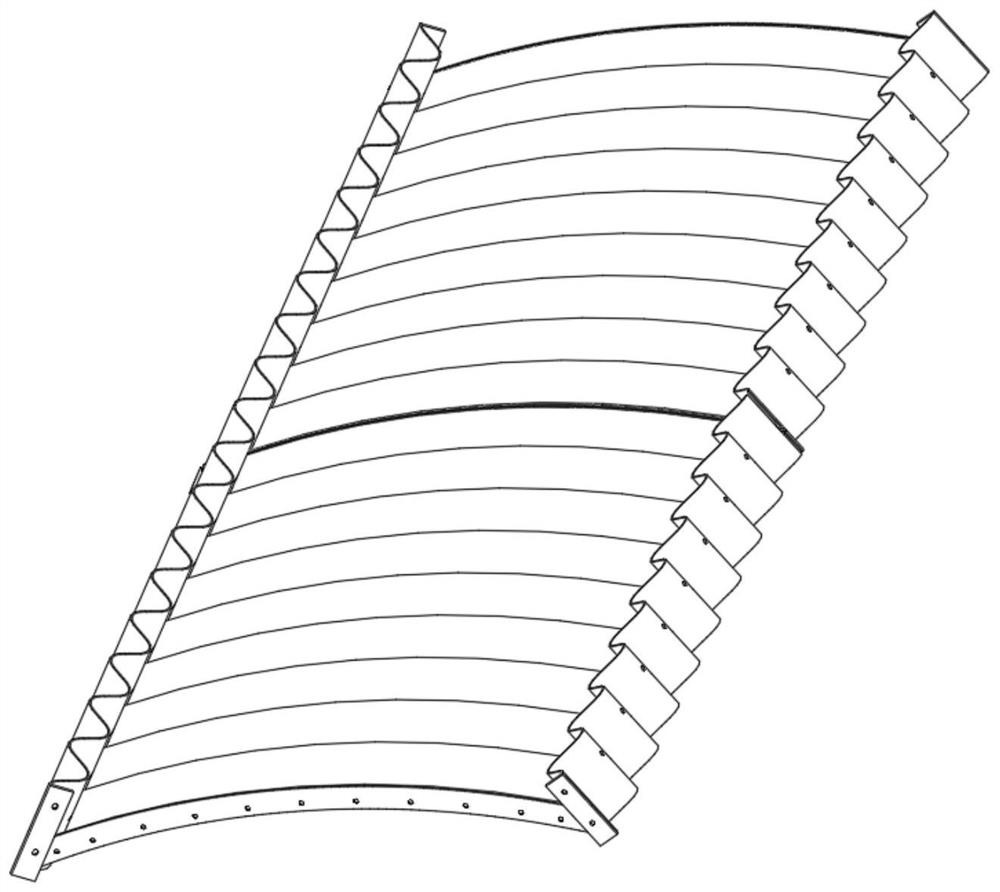

[0041] (1) The reserved section 14 of the corrugated steel plate 1 is cut obliquely from the crest 11 to the end of the wave waist 12, and the trough 13 of the corrugated steel plate 1 is continuous.

[0042] The arc-shaped corrugated steel plate can be arc-shaped corrugation in the form of a sinusoidal curve, including a semicircular-like crest 11 , a wave waist 12 similar to a straight line, and a trough 13 with the same shape as the crest and opposite direction. A section of length is reserved on the corrugated end of the corrugated steel plate (the end is the side perpendicular to the corrugated direction of the corrugated steel plate) as the height of the corrugated flange, and the peak...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap