Drop test frame for testing safety performance of detonator explosive

A technology of safety performance and test stand, which is applied in the direction of impact test, machine/structural component test, measuring device, etc. It can solve the problems of inaccurate control of height and no platform, etc., and achieve the effect of reliable structure and accurate experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred mechanism and motion realization method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

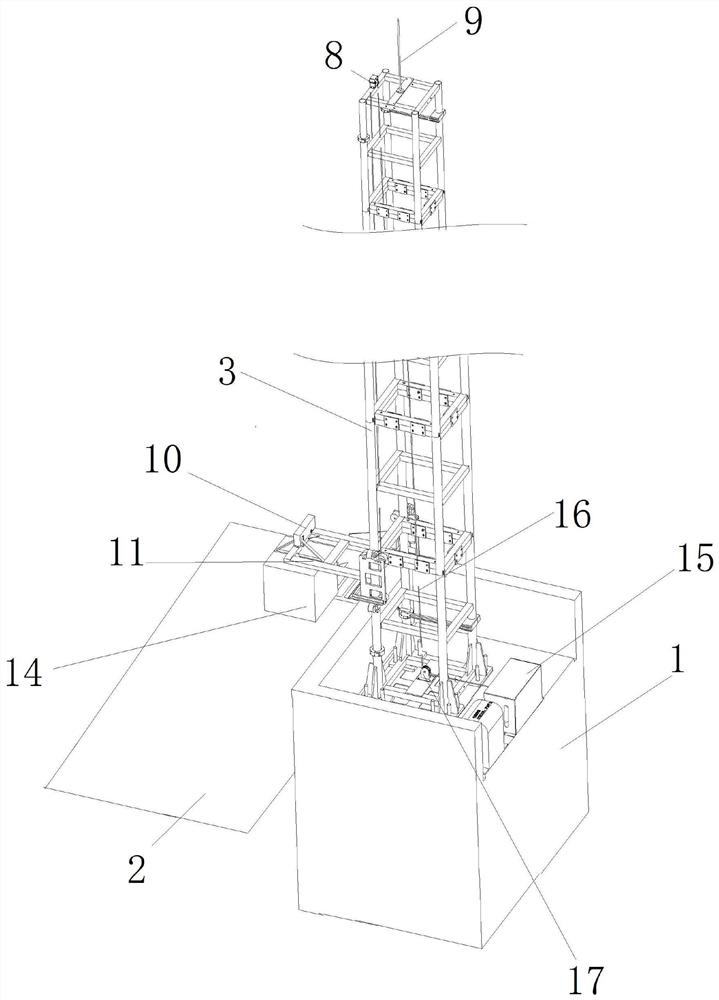

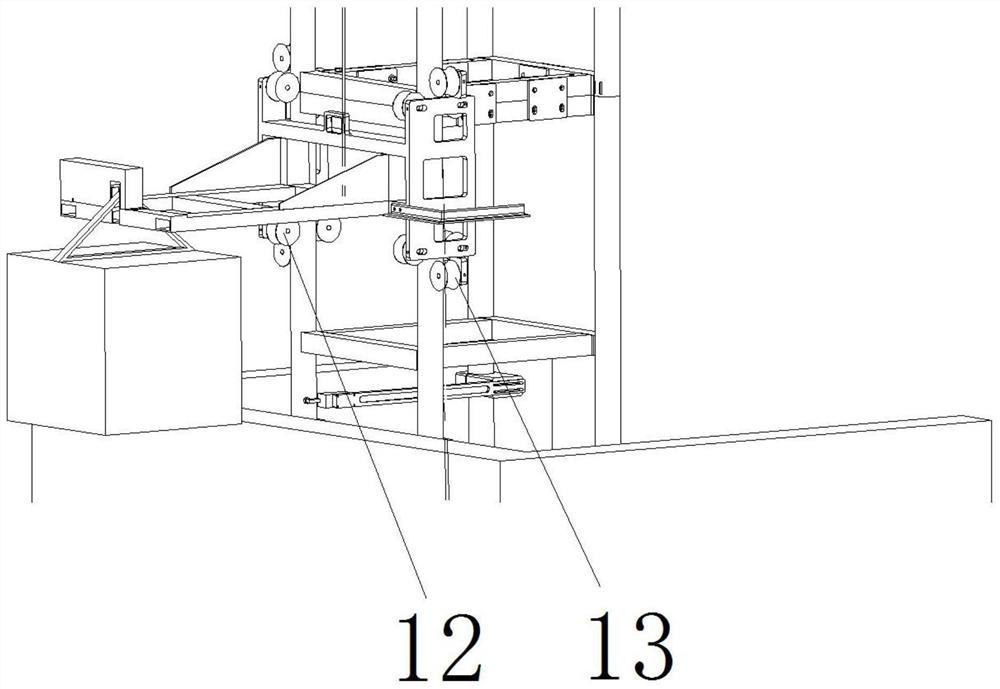

[0022] Such as figure 1 with figure 2 as shown,

[0023] A drop test stand for testing the safety performance of detonator explosives, comprising:

[0024] The bottom base 1; the bottom base 1 is mainly a foundation constructed of reinforced concrete, which generally extends into the ground, leaving only the platform on the ground; similarly, there is a drop receiving platform 2 on the ground, and its main body is also a cement structure , has a certain strength, which is used to undertake the detonator under test;

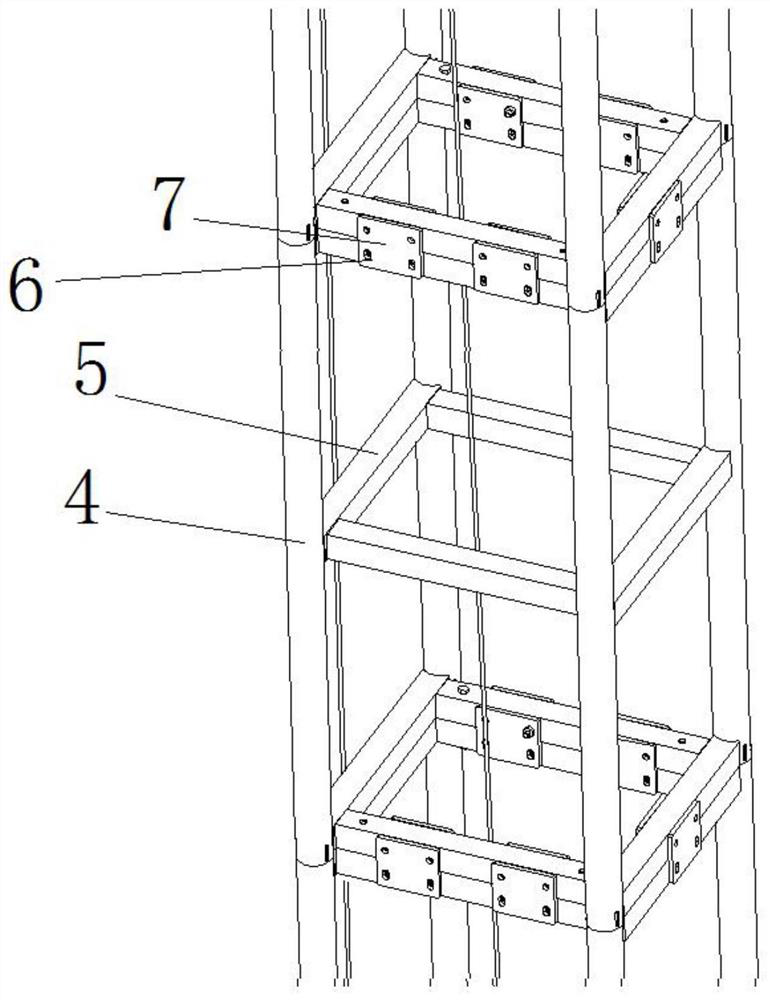

[0025] Vertical fixture 3, described vertical fixture 3 is fixed on the described bottom base 1; As image 3 As shown, the vertical fixed seat 3 is composed of several fixed seat assemblies, each of which has four uprights 4 and fixed beams 5 for fixing the four uprights...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com