Material sampling inspection method based on flexible detection technology

A detection technology and material technology, applied in the field of warehouse material quality detection, can solve problems such as poor flexibility, difficulty in upgrading, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

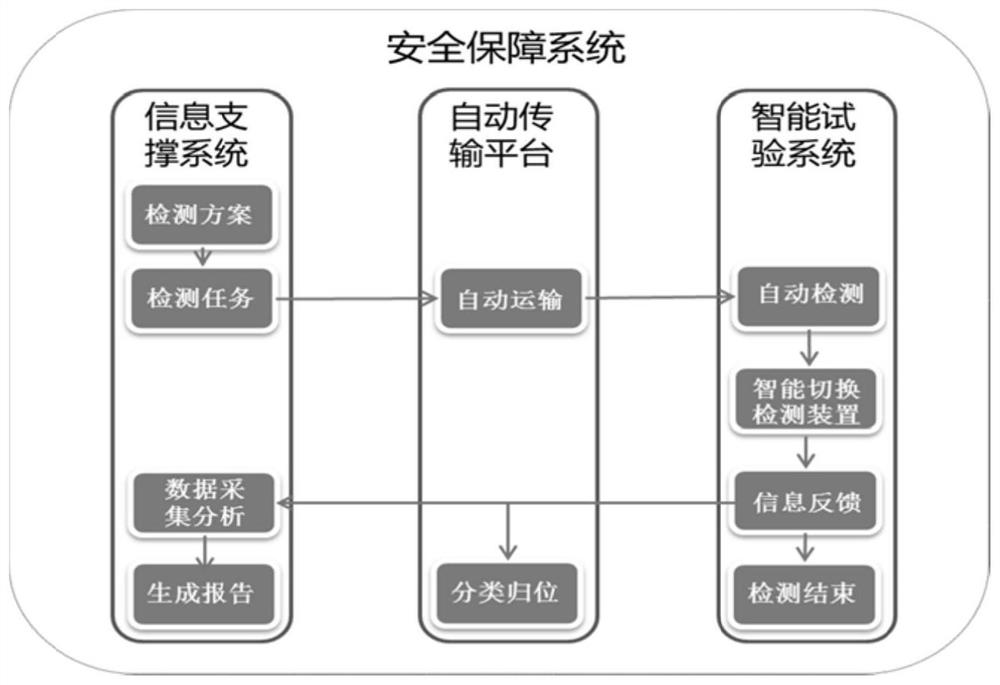

[0031] figure 1 Among them, the technical solution of the present invention provides a method for random inspection of materials based on flexible detection technology, and its invention points are:

[0032] 1) After the detection object arrives in the warehouse, according to the arrival information and detection plan collected online by the Internet of Things, the random inspection task is obtained online, and the detection task combination detection module is automatically established;

[0033] 2) Scan the QR code of the inspected equipment, then scan the QR code of the tray, automatically identify the test product, and send the sealed sample to the waiting area to automatically transport the test product to the station for testing;

[0034] 3) After the control system receives the order, it will carry out the automatic detection operation, and adopt the means of au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com