Ulna coracoid process locking plate

A coronoid and locking plate technology, which is applied in the field of medical devices, can solve the problems of easy failure, loss of fixation strength, and low fixation strength of anchors, so as to facilitate fracture recovery and improve the effect of fracture fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

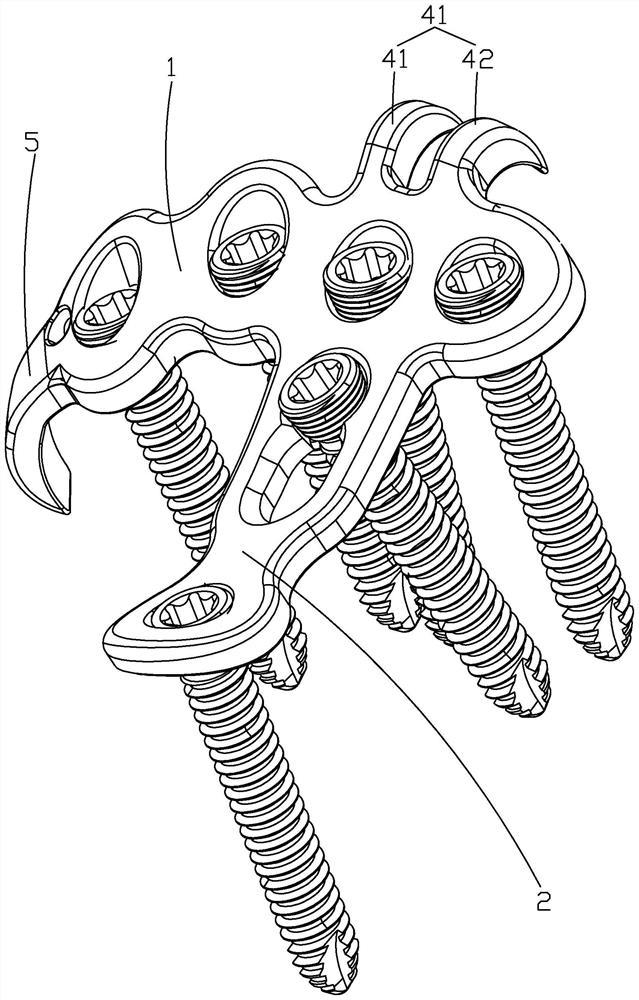

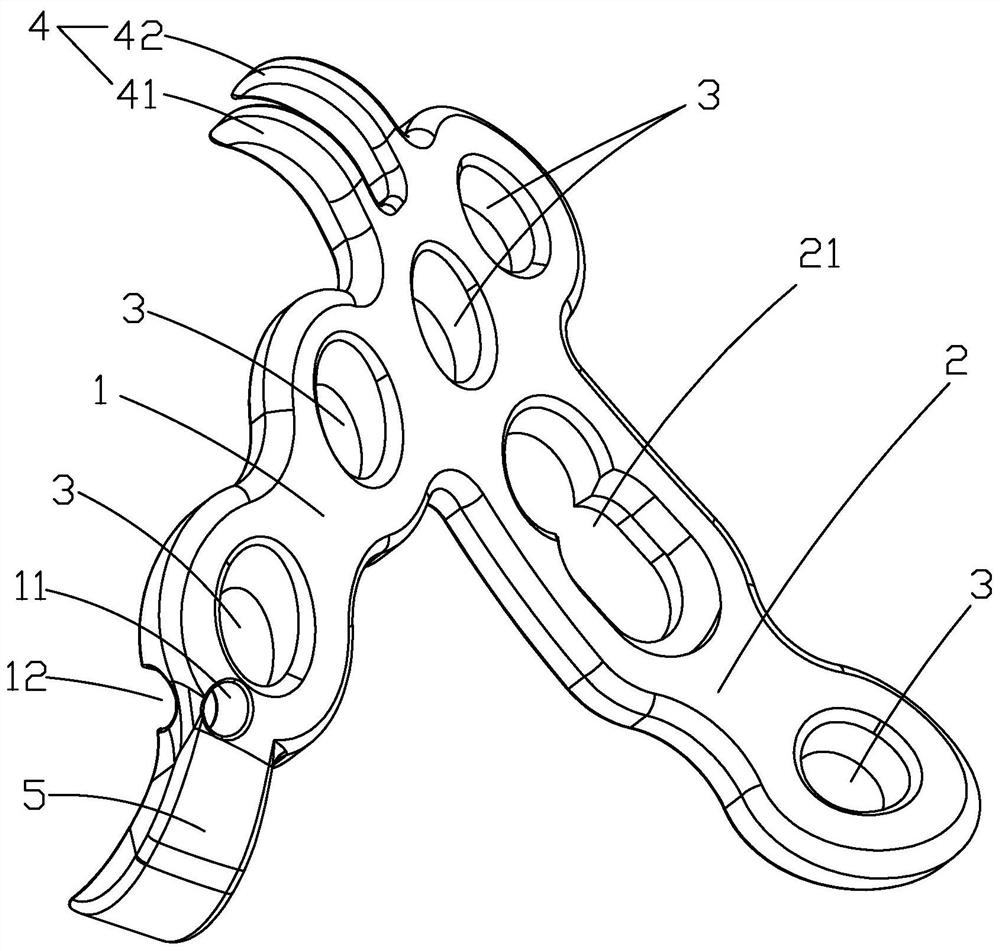

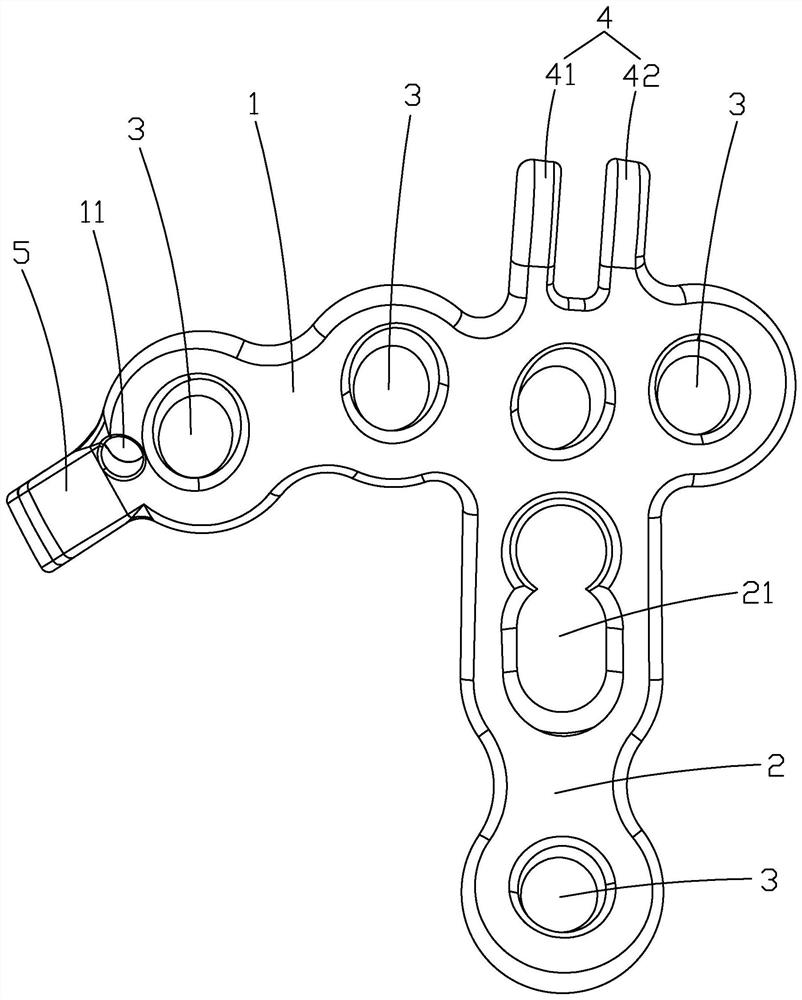

[0028] Please refer to the attached figure 1 To attach Figure 4 , an embodiment of the present invention provides a locking plate for the coronoid process of the ulna, including a transverse locking part 1 and a longitudinal locking part 2 arranged crosswise, and the fitting surface of the transverse locking part 1 is adapted to the transverse anatomical structure of the coronoid The arc-shaped surface structure of the longitudinal locking part 2 is an arc-shaped curved surface structure suitable for the longitudinal anatomical structure of the coronoid process. The transverse locking part 1 and the longitudinal locking part 2 are provided with a number of locking holes 3, and the longitudinal locking The end position of the part 2 is connected with a coronoid hook claw 4 capable of acting on the coronoid tip. It can be understood that in this embodiment, the intersecting transverse locking parts 1 and longitudinal locking parts 2 cooperate with each other to form the main s...

Embodiment 2

[0039] Please refer to the attached Figure 5 The difference between the present embodiment and the first embodiment is only that the setting position of the combination hole 21 on the longitudinal locking part 2 is different. Specifically, in the first embodiment, the setting position of the combination hole 21 on the longitudinal locking part 2 is not in the horizontal direction The vertical and horizontal connection of the locking part 1 and the vertical locking part 2 , and the combination hole 21 in this embodiment is located at the vertical and horizontal connection of the horizontal locking part 1 and the vertical locking part 2 . However, those skilled in the art should understand that in other embodiments, the combination hole 21 may also be set at other positions of the longitudinal locking portion 2, and is not limited to the specific implementation manners disclosed in the first and second embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com