Mixing system for thermal insulation boards

A thermal insulation board and thermal insulation board technology, applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of being unable to adapt to the special feeding and unloading characteristics of light materials, small volume and low density of monomers, and achieve The effect of shortening the waiting time for feeding materials, reasonable space allocation, and compact design and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

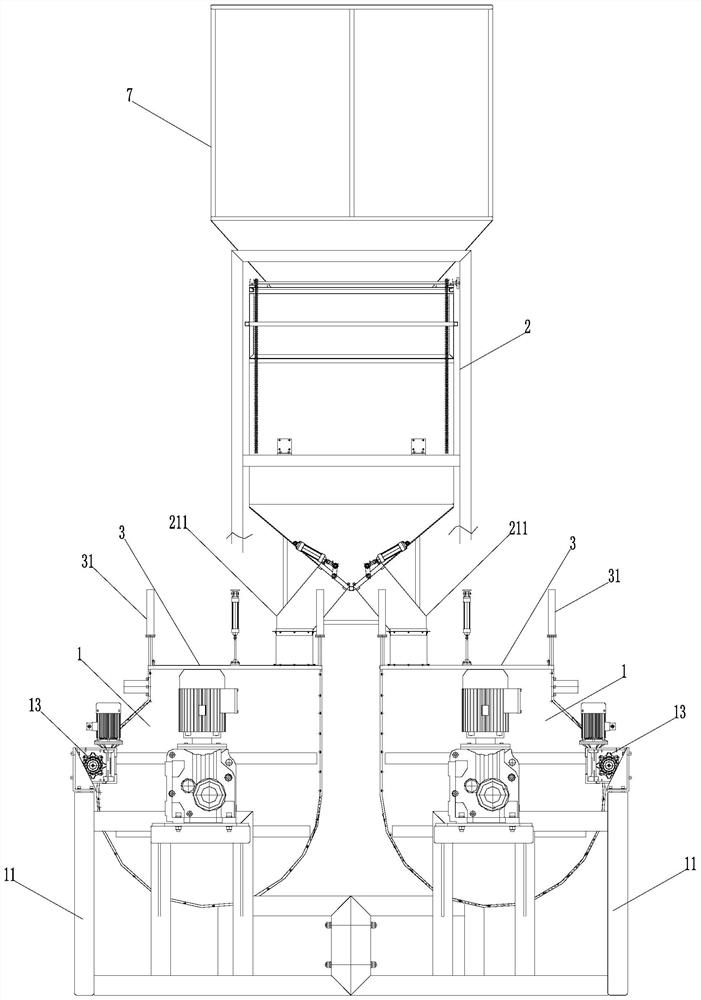

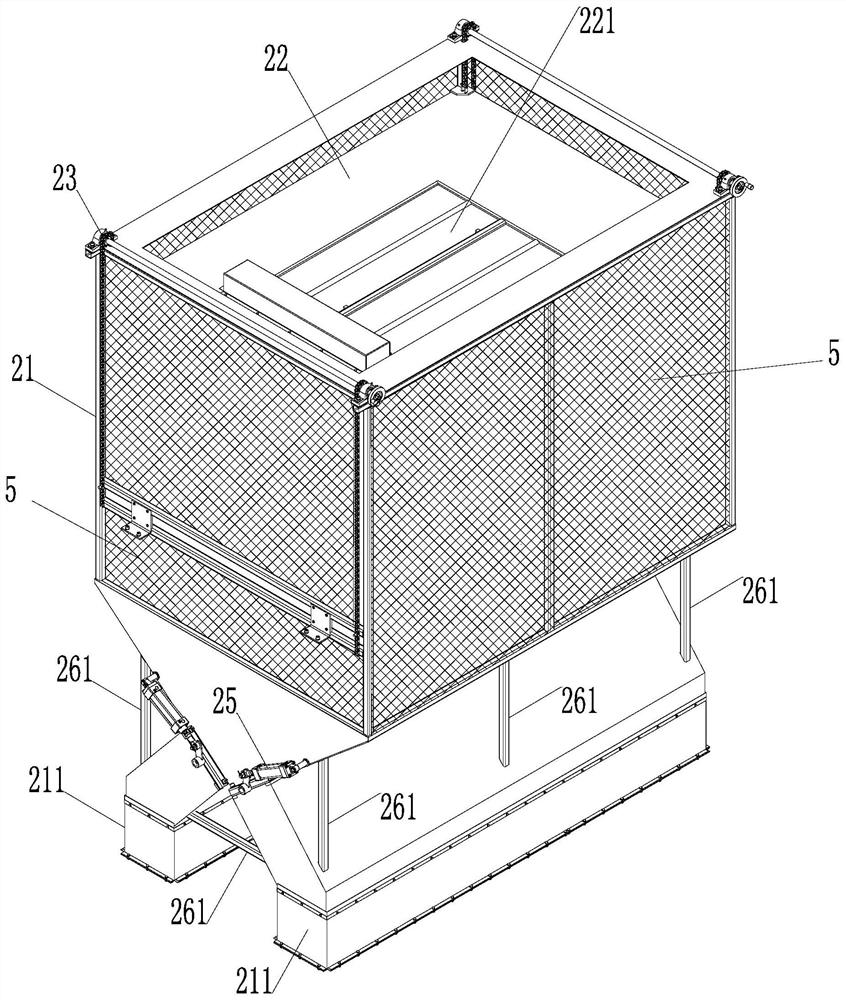

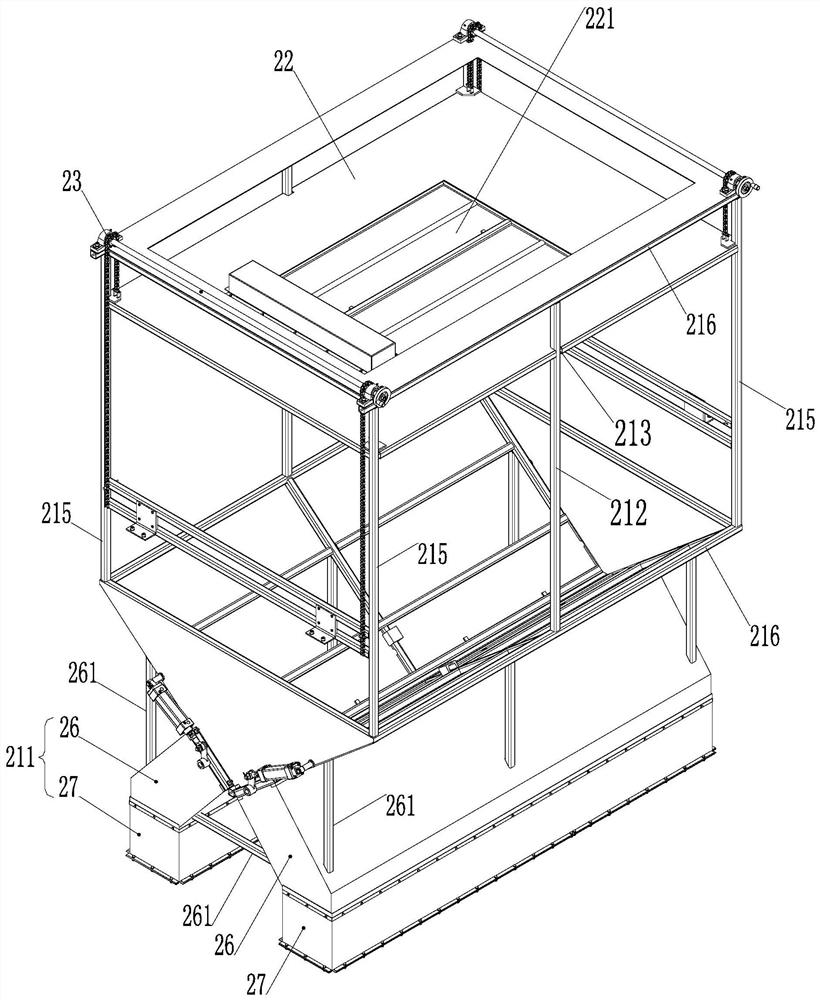

[0090] As shown in the figure, this embodiment discloses a material mixing system for thermal insulation boards, which includes a material stirring device 1 and a material metering device 2 for metering materials; Metering, the metered material is discharged through the discharge port 211 of the material metering device 2 and enters the material stirring device 1 for stirring. After the material is stirred in the material stirring device 1, it is discharged through the feed port 122 of the material stirring device 1.

[0091] Preferably, see attached Figures 2 to 4 , The material metering device 2 measures the material by volumetric metering. Light granular materials have low density and high bulkiness. The traditional gravity measurement method is cumbersome to operate and requires high equipment, which is not conducive to improving production speed.

[0092] preferred, see figure 1 , 10 As shown in 11 and 11, the material mixing system of the thermal insulation board inc...

Embodiment 2

[0146] Refer to attached Figures 1 to 22 In this embodiment, a method of using the "mixing system for thermal insulation boards" disclosed in the present invention is exemplified. This method is just an example of the many ways to use it.

[0147] When in use, the mixing system of the insulation board is fixedly installed and placed in the production system of the insulation board. Below the material mixing system of the insulation board: a material transfer device for the lower production process is arranged at a position corresponding to the relief port 111 . Above the mixing system of the thermal insulation board: a storage bin 7 is arranged corresponding to the position of the feed inlet 221 of the dividing plate (that is, the storage bin 7 is erected above the material metering device 2 through a bracket).

[0148] When the mixing system of the insulation board is self-assembled: above the material stirring device 1: the cover plate 3 is fixedly installed at the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com