Construction waste garbage cleaning mechanism with recycling structure

A construction waste and garbage cleaning technology, which is applied in grain processing, mechanical equipment, springs/shock absorbers, etc., can solve the problems affecting the collection efficiency of steel bars and the inability to collect steel bars, etc., to facilitate the treatment of concrete slag, improve the service life, and quickly The effect of dealing with concrete slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

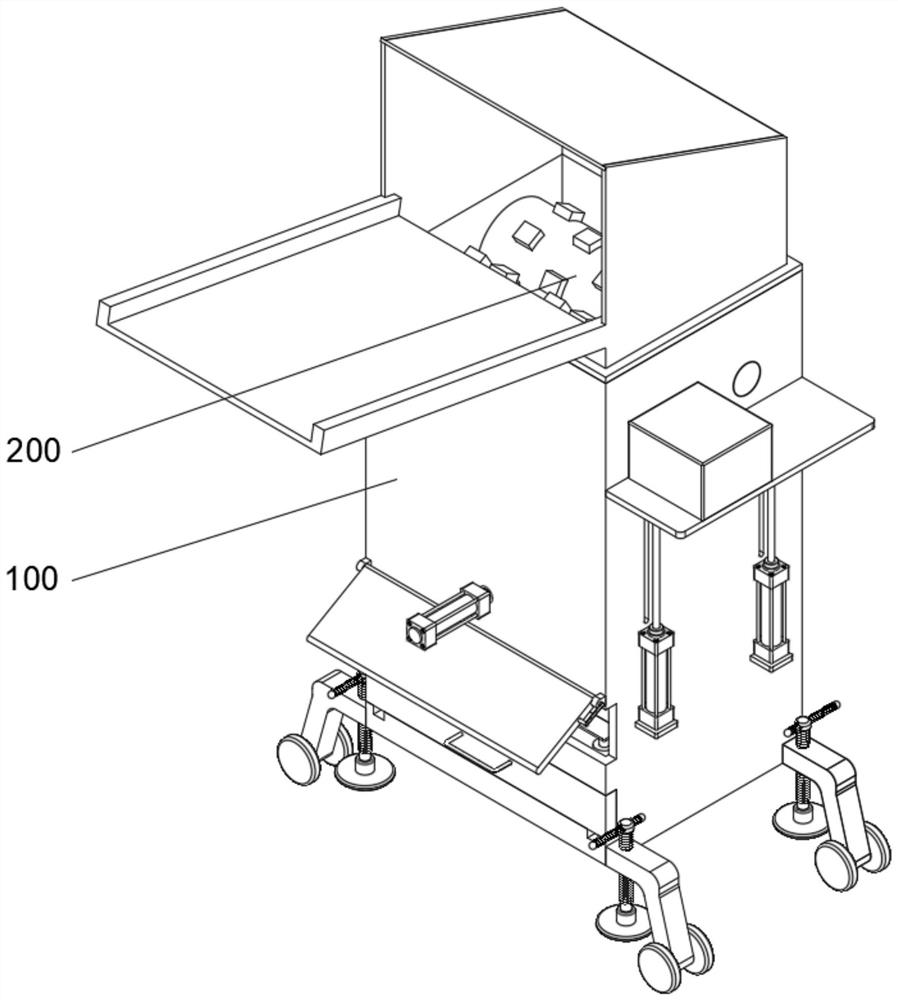

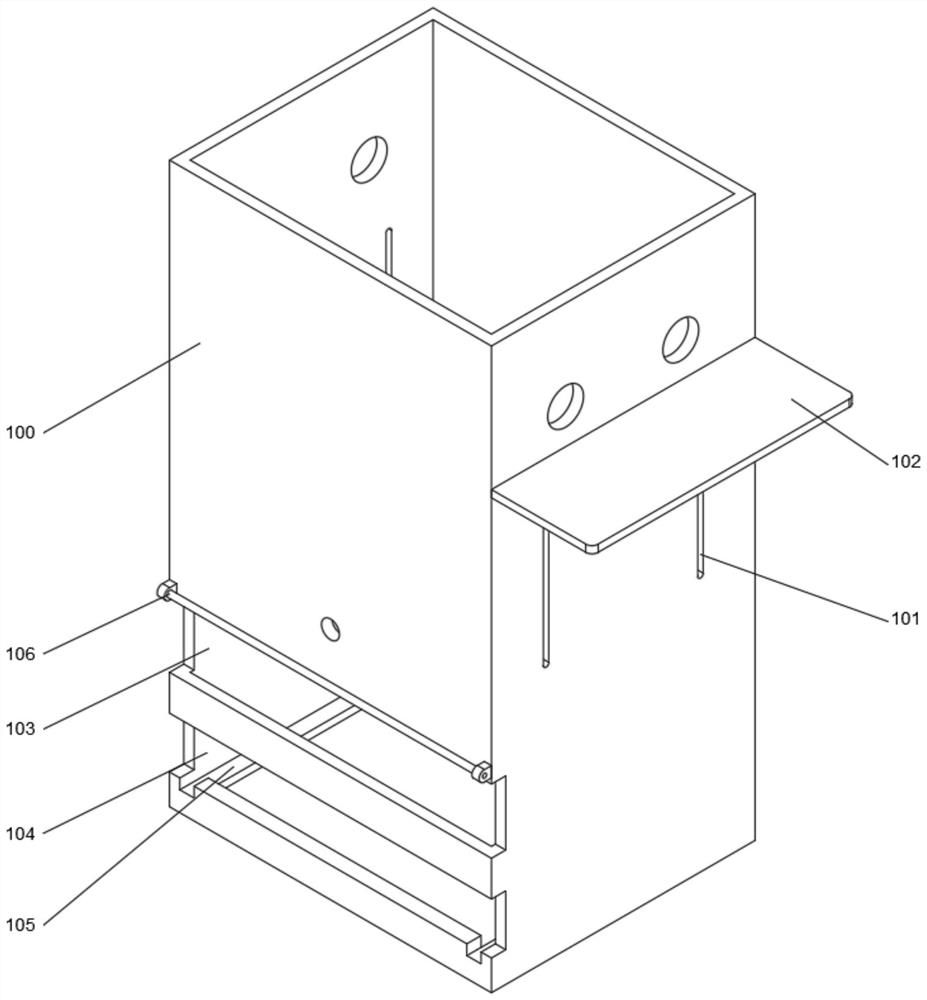

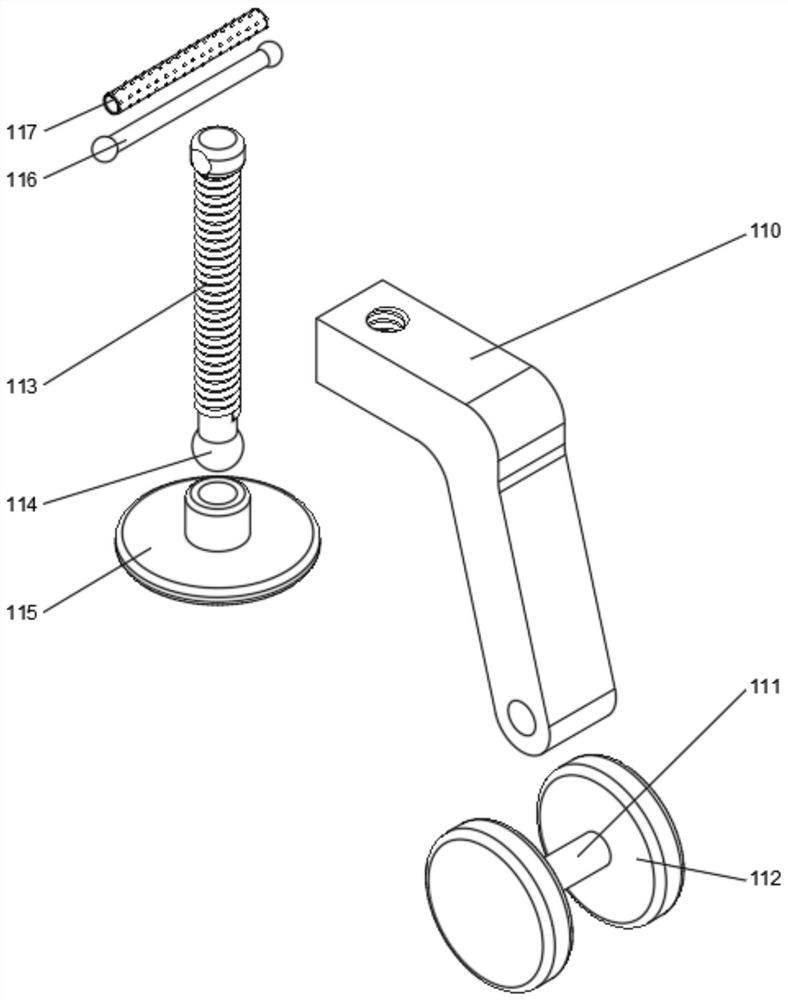

[0054] see Figure 1-Figure 14 As shown, a construction waste garbage cleaning mechanism with a recycling structure is provided, including a housing 100 and a crushing device 200 installed inside the housing 100. Slideways 101 are provided at both ends of the outer walls on both sides of the housing 100. One side of the housing 100 The first mounting plate 102 is fixedly connected, and the crushing device 200 at least includes:

[0055] Pulverizing mechanism 210, pulverizing mechanism 210 comprises rotating roller 211, and rotating roller 211 is connected to the inner wall of housing 100 both sides in rotation, and one end of two rotating rollers 211 is all fixedly connected with gear 212, meshes between two gears 212, the first installation A motor 213 is installed on the surface of the plate 102, and one end of the output shaft of the motor 213 passes through the side of the housing 100 and is fixedly connected to one end of one of the rotating rollers 211;

[0056] The col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com