PtIn-coated MFI catalyst as well as preparation method and application thereof

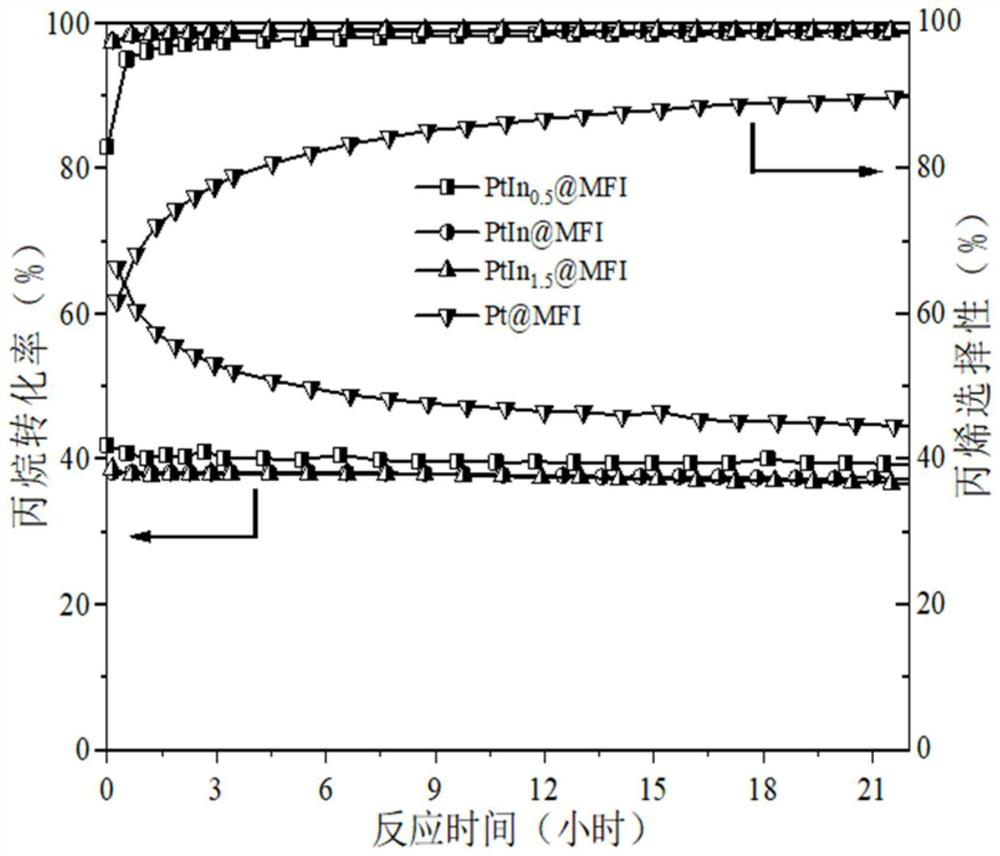

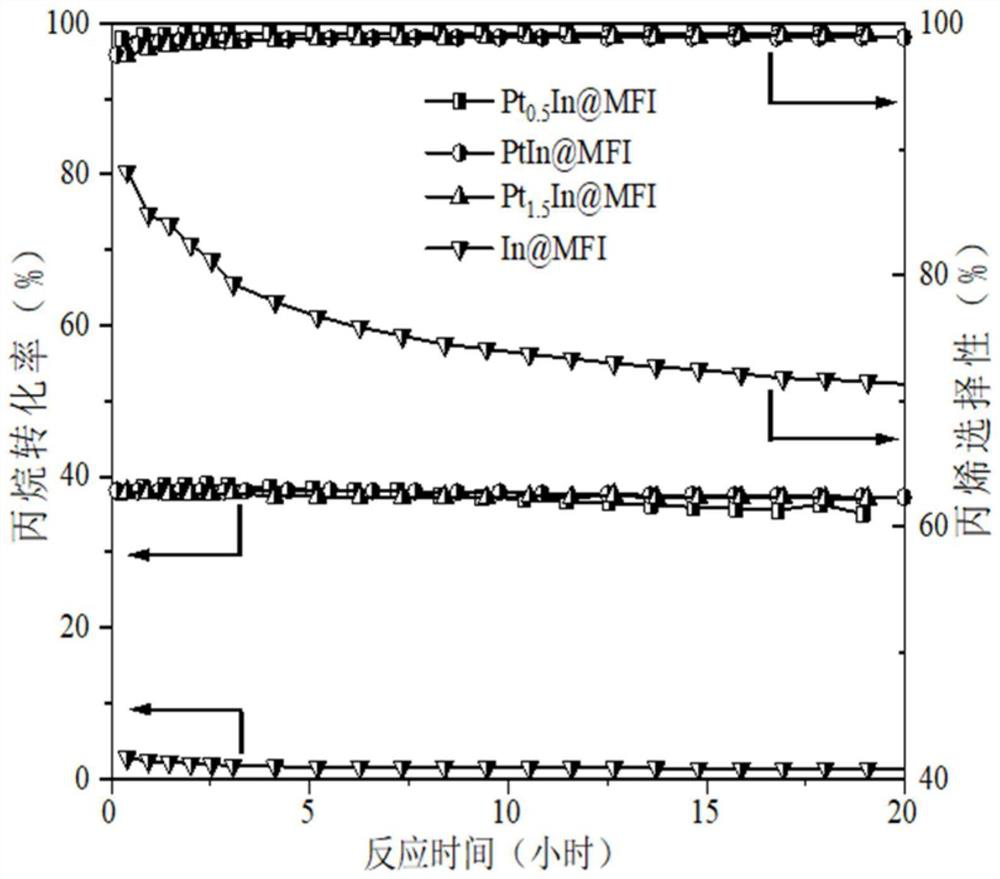

A catalyst, pt-in technology, applied in the field of PtIn@MFI catalyst and its preparation, can solve the problems of easy coking and deactivation, high price, unfriendly environment, etc., achieve high catalytic activity and stability, less equipment, and easy-to-use products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a method for preparing the PtIn@MFI catalyst described in the above technical solution, comprising:

[0036] Pt(NH 3 ) 4 (NO 3 ) 2 (tetraammineplatinum nitrate) aqueous solution and TPAOH (tetrapropyl ammonium hydroxide) solution are mixed to obtain the first mixed solution;

[0037] TEOS (tetraethyl orthosilicate) is mixed with the first mixed solution to obtain the second mixed solution;

[0038] Will In(NO 3 ) 3 ·xH 2 O (indium nitrate hydrate) solution is mixed with the second mixed solution to obtain the third mixed solution;

[0039] subjecting the third mixed solution to hydrothermal treatment to obtain a treated product;

[0040] The processed product is calcined to obtain a PtIn@MFI catalyst.

[0041] In the present invention, during the preparation of the PtIn@MFI catalyst, SiO 2 , TPAOH, H 2 The molar ratio of O, Pt and In is preferably 1:(0.3~0.5):(30~50):(0.001~0.009):(0.001~0.009), more preferably 1:(0.35~0.45):(35...

Embodiment 1

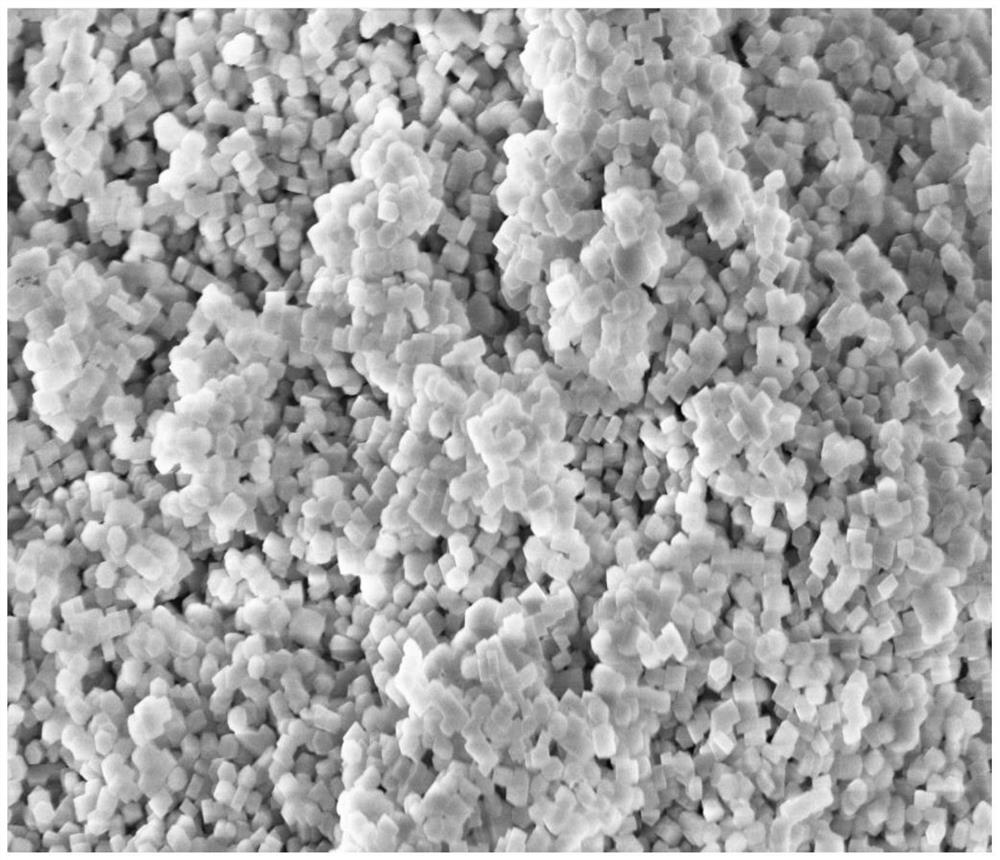

[0073] The preparation of the Pt-In nano-catalyst encapsulated in the MFI molecular sieve of embodiment 1

[0074] 0.27g of In(NO 3 ) 3 ·xH 2 O was dispersed in 10mL of deionized water, stirred at room temperature to form solution A; 13g of TPAOH (mass fraction 25%) was dispersed in 16.5g of deionized water, stirred evenly; then 0.8mL of 0.000225mol / mL of Pt(NH 3 ) 4 (NO 3 ) 2 Aqueous solution, stirred in a water bath at 35°C for 10 minutes; then added 8.32 g of TEOS to it, stirred in a water bath at 35°C for 20 minutes to form solution D; took 1 mL of solution A and added to solution D, stirred in a water bath at 35°C for 9 hours to form a solution E: Transfer the solution E to a hydrothermal kettle for hydrothermal treatment at 180°C for 96 hours.

[0075] The hydrothermally treated product was washed three times by centrifugation with deionized water at a speed of 10,000 rpm for 5 minutes; then dried at 70°C for 12 hours; finally calcined in an air atmosphere at a ca...

Embodiment 2

[0079] The preparation of the Pt-In nano-catalyst encapsulated in the MFI molecular sieve of embodiment 2

[0080] 0.27g of In(NO 3 ) 3 ·xH 2 O was dispersed in 10mL deionized water, and stirred at room temperature to form solution A; 13g of TPAOH (mass fraction 25%) was dispersed in 15.5g of deionized water, stirred evenly; then 0.8mL of 0.000225mol / mL of Pt (NH 3 ) 4 (NO 3 ) 2 Aqueous solution, stirred in a 35°C water bath for 10min; then added 8.32g of TEOS to it, stirred in a 35°C water bath for 20min to form solution D; took 2mL of solution A and added it to solution D, stirred in a 35°C water bath for 9h to form a solution E: Transfer the solution E to a hydrothermal kettle for hydrothermal treatment at 180°C for 96 hours.

[0081] The product after hydrothermal treatment was centrifugally washed with deionized water at a speed of 10,000 rpm for 5 minutes; then dried at 70°C for 12 hours; and finally calcined at a temperature of 550°C for 4 hours in an air atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com