Injection mold device for automobile sealing parts

A technology for injection molds and seals, which is applied in the field of injection mold devices for automotive seals, can solve problems such as stress indentation at the injection port, impact on production quality, and easy material stuck in the injection port, so as to achieve stability and ensure sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

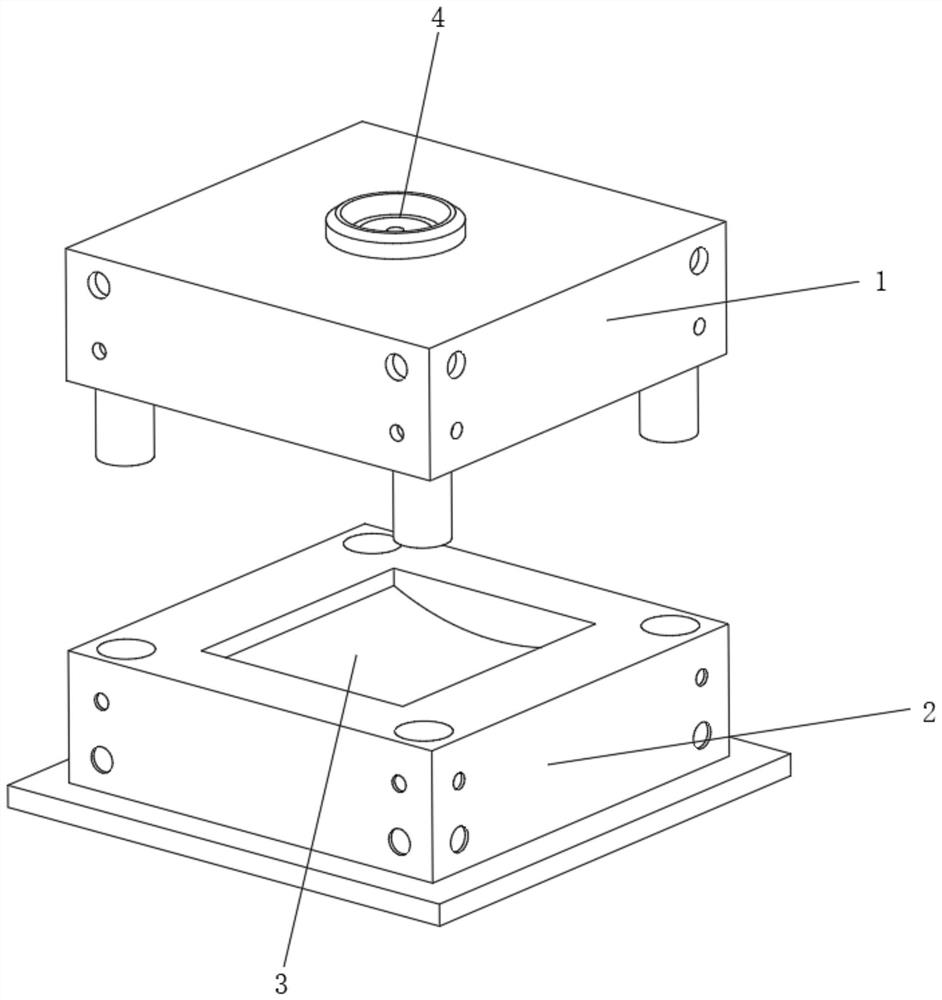

[0039] Such as Figure 1-4 As shown, the present invention provides a technical solution: an injection mold device for automotive seals, including an upper mold base 1, a lower mold base 2 corresponding to the upper mold base 1, and the upper mold base 1 and the lower mold base 2. Die grooves 3 are provided inside, injection port 4 is provided above the upper mold base 1, a connection stabilization mechanism 5 is provided on the outside of the top of the injection port 4, and a movable swing groove 6 is arranged near the bottom of the injection port 4, and the movable swing groove The top inside of 6 is evenly and fixedly connected with a material guide limiting mechanism 7, and the inside of the inner wall of the injection port 4 and below the movable swing groove 6 is provided with a separating shoveling mechanism 8;

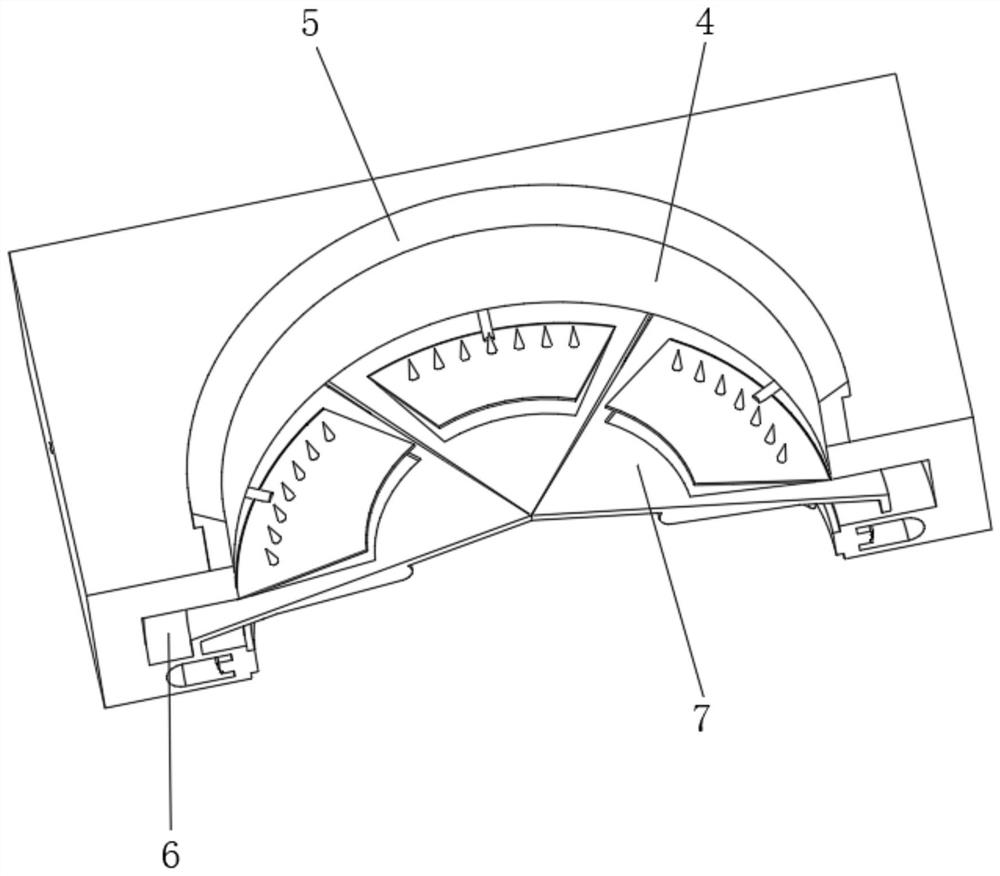

[0040] The material guide limiting mechanism 7 is spliced by several adjusting sealing plates 71, and the top of each adjusting sealing plate 71 is provided...

Embodiment 2

[0044] Such as Figure 5-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: an injection mold device for automobile seals. Fixedly connected, the output end at the bottom of the conduction cone 731 communicates with the one-way air guide piston rod 75 , and the input end of the conduction cone 731 is fixedly connected with a drag reducing contact tube 732 . The tightness of the conductive structure can be guaranteed without air bubbles.

[0045] The input end of the drag reducing contact tube 732 is fixedly connected with a material guide contact plate 733, elastic swing doors 734 are arranged on the left and right sides of the material guide contact plate 733, and the inner surface of the conduction tapered tube 731 is uniformly provided with a blocking fan 735. Realize the cleaning of air bubbles in the material, and at the same time, block the fan 735 from blocking the circulation of the injected material, reducing the outflow ph...

Embodiment 3

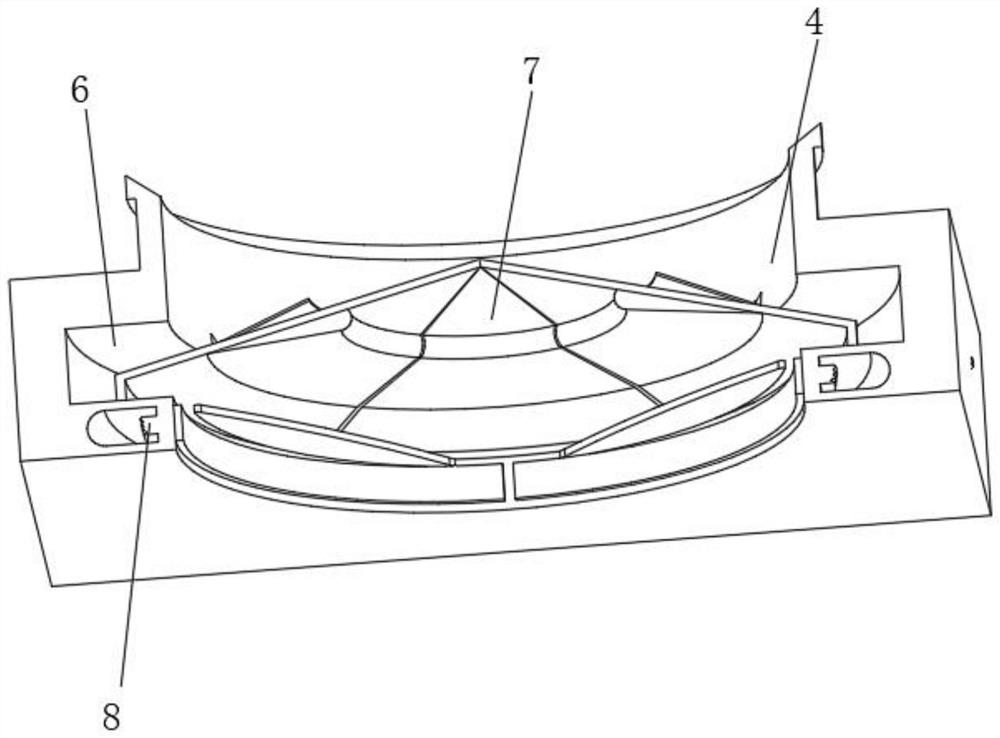

[0047] Such as Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: an injection mold device for automobile seals, the partition shoveling mechanism 8 includes a storage heat absorption groove 81, and the storage heat absorption groove 81 is set Inside the inner wall of the injection port 4, one side of the storage heat absorption groove 81 is fixedly connected with an extension drive block 82, and the inside of the extension drive block 82 is fixedly connected with a heat conduction bump 83, and the heat conduction bump 83 extends to the side of the storage heat absorption groove 81. internal.

[0048] The inner wall of the injection port 4 is rotationally connected with a cutting knife plate 84 above the extension drive block 82 , the top of the material cutting knife plate 84 is arranged correspondingly to the contact bump 76 , and the bottom of the material cutting knife plate 84 is corresponding to the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com