Antibacterial degradable medical suture

A technology of suture and antibacterial agent, applied in the field of antibacterial and degradable medical suture, can solve the problems of good absorbability and antibacterial performance, unfavorable antibacterial durability wound tissue healing, etc., to achieve the ability to promote tissue healing, high antibacterial and anti-inflammatory activity, The effect of promoting tissue healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

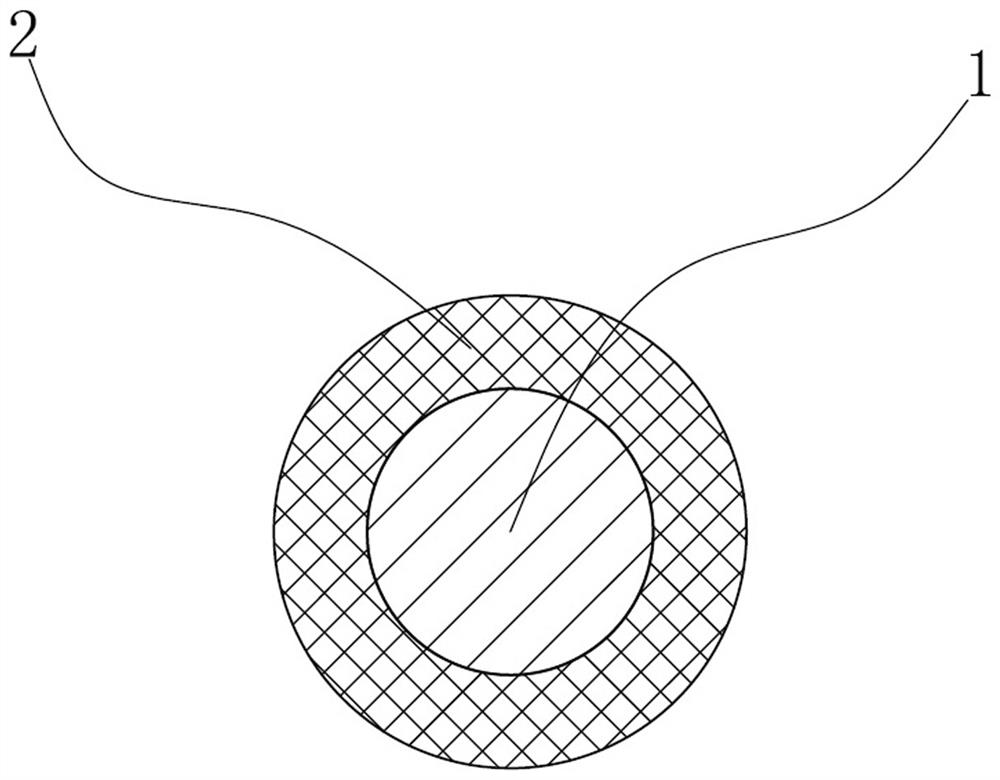

[0028] The antibacterial and degradable medical suture thread of this embodiment includes a core thread 1 made of degradable polylactic acid fiber thread and a braided thread layer 2 wrapped around the core thread. The braided thread layer is mainly composed of absorbable suture thread and degradable suture thread. The degradable suture is spun from degradable polylactic acid fiber, and the absorbable suture is mainly made of the following raw materials by weight:

[0029] Collagen: 10; chitosan oligosaccharide: 20; γ-polyglutamic acid: 4.0; seaweed selenium polysaccharide: 1.0; silk fibroin: 3.0; γ-polyglutamic acid loaded with medical antibacterial agent chitosan quaternary ammonium salt , the mass percentage of chitosan quaternary ammonium salt of γ-polyglutamic acid is 2%.

[0030] The specific processing method of the suture thread and the specific spinning processing method can all be conventional processing methods in the art.

Embodiment 2

[0032] The antibacterial and degradable medical suture thread of this embodiment includes a core thread 1 made of degradable polylactic acid fiber thread and a braided thread layer 2 wrapped around the core thread. The braided thread layer is mainly composed of absorbable suture thread and degradable suture thread. The degradable suture is spun from degradable polylactic acid fiber, and the absorbable suture is mainly made of the following raw materials by weight:

[0033] Collagen: 15; Chitosan Oligosaccharide: 18; β-Polyglutamic Acid: 2.0; Dextran Selenite: 0.8; Silk Fibroin: 2.0; The mass percentage of β-polyglutamic acid is 2.5%.

Embodiment 3

[0035] The antibacterial and degradable medical suture thread of this embodiment includes a core thread 1 made of degradable polylactic acid fiber thread and a braided thread layer 2 wrapped around the core thread. The braided thread layer is mainly composed of absorbable suture thread and degradable suture thread. The degradable suture is spun from degradable polylactic acid fiber, and the absorbable suture is mainly made of the following raw materials by weight:

[0036] Collagen: 13; chitosan oligosaccharide: 15; γ-polyglutamic acid: 3.0; arabinoxylan selenite: 0.9; silk fibroin: 2.5; Chitosan quaternary ammonium salt, the mass percentage of chitosan quaternary ammonium salt in γ-polyglutamic acid is 3.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com