Installation structure and installation method of a prefabricated floor slab

A technology for installing structures and floors, which is applied to floors, building components, building structures, etc., can solve the problems of multiple floors, cumbersome and other problems, and achieve the effect of simple installation and connection process, reduced complexity, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 2-7 The application is described in further detail.

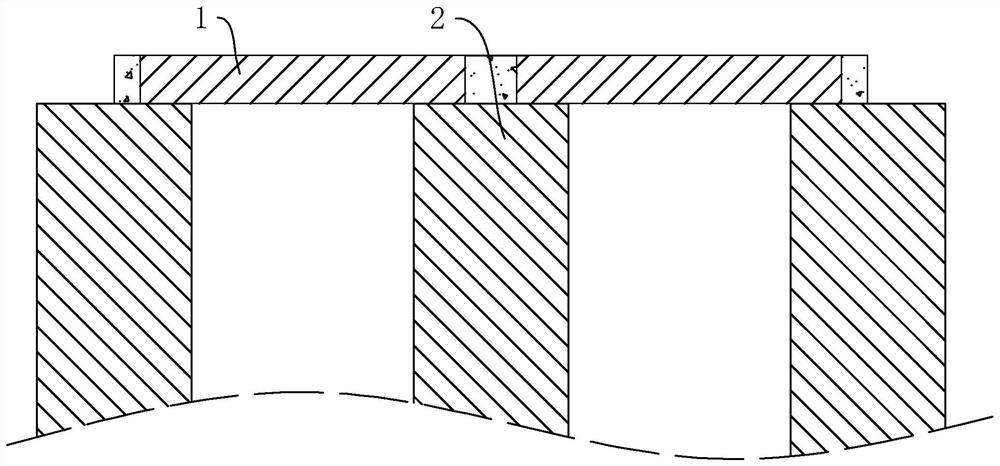

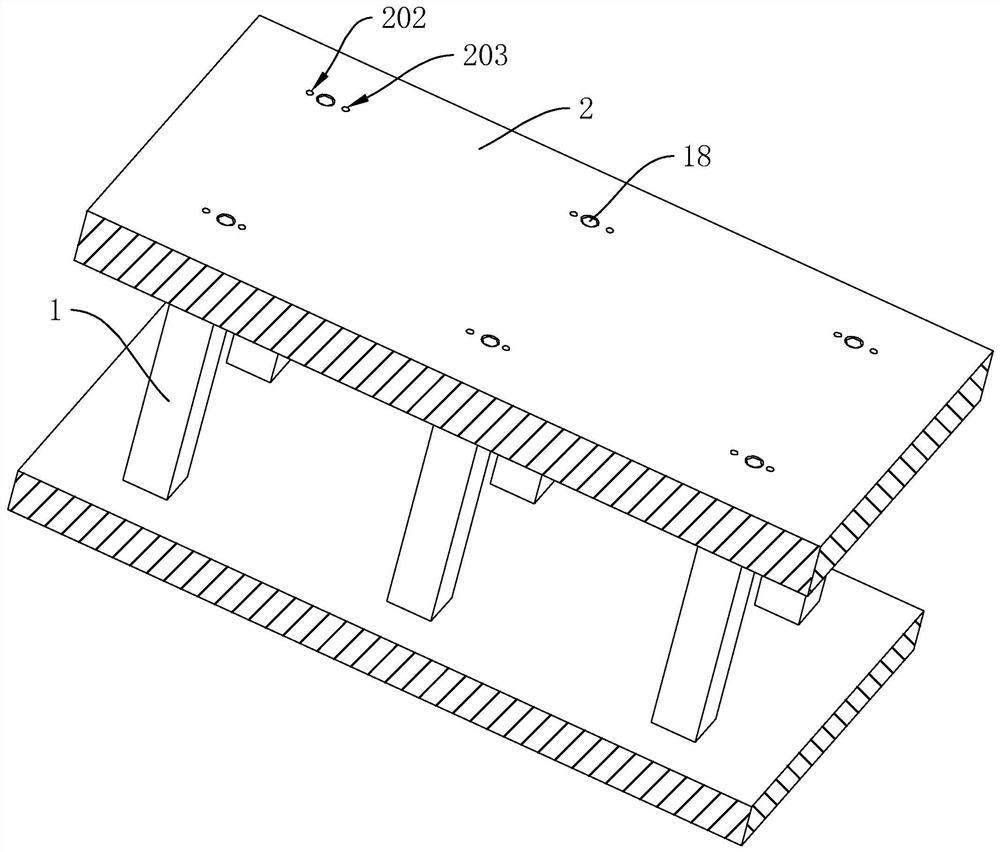

[0041] For the installation structure of a prefabricated floor slab disclosed in the embodiment of the present application, see figure 2 The installation structure of the prefabricated floor slab includes a floor slab 2, and the floor slab 2 is poured with concrete and steel bars to form an integrated prefabricated structure.

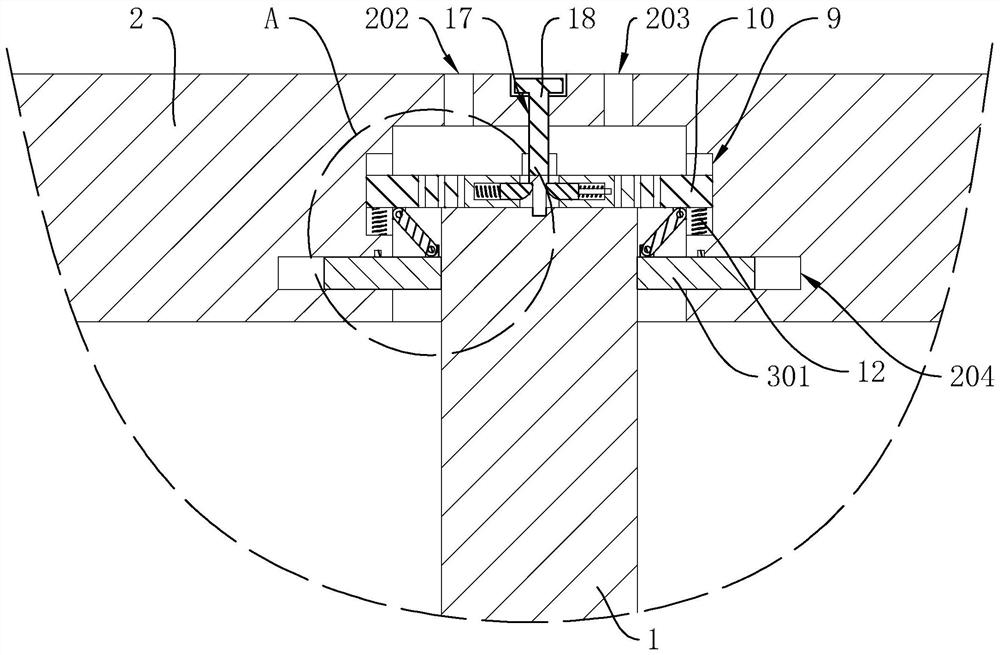

[0042] see image 3 and Figure 4 Before the floor 2 is installed, the support beam 1 is first poured on the floor. In order to facilitate the connection between the floor 2 and the support beam 1, the support beam 1 can adopt a long column structure with a square top end. The bottom of the floor 2 is provided with a plurality of installation slots 201. The slots of the installation slots 201 are square in shape. The size of the slots of the installation slots 201 and the size of the top end surface of the support beam 1 are multiplied. The installation slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com