A self-stabilizing prefabricated formwork support system and its construction method

A formwork support and assembly technology, which is applied in the preparation of pillars and building components on site, and the processing of building materials, etc., can solve the problem of formwork support being difficult to stabilize, and achieve the effect of improving the support force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

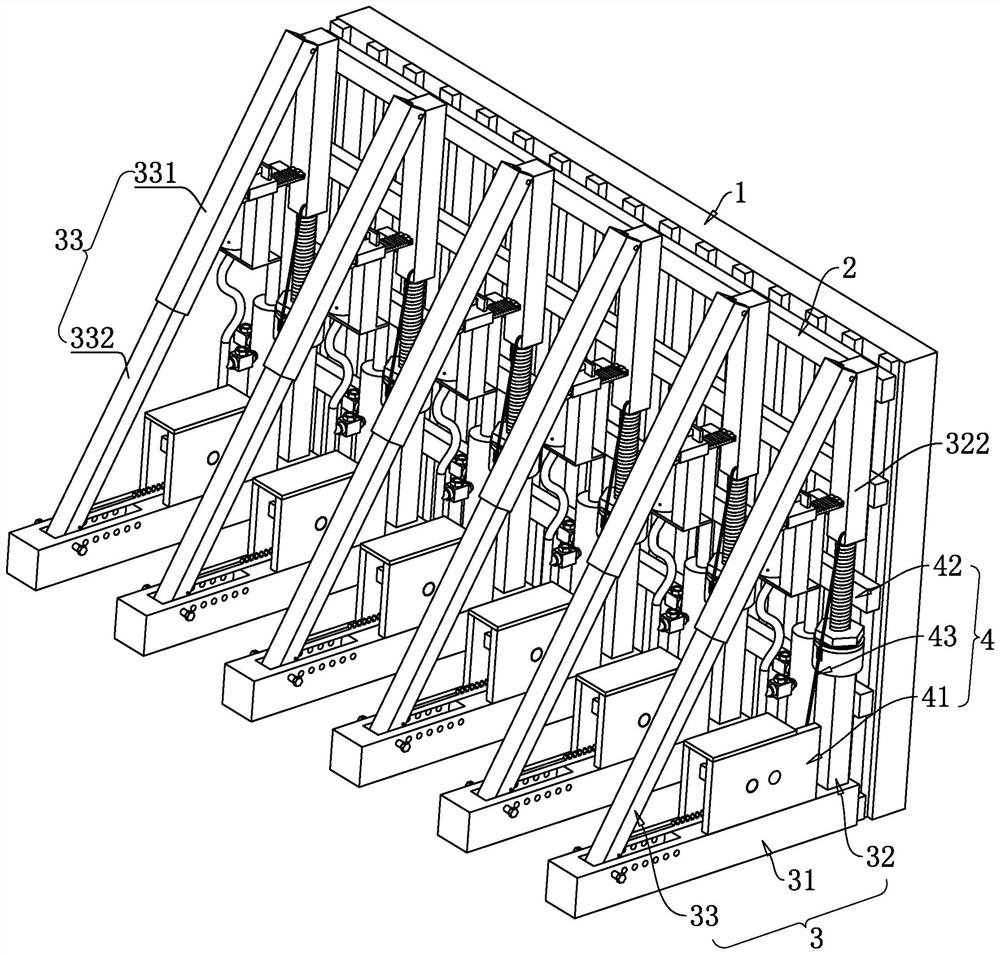

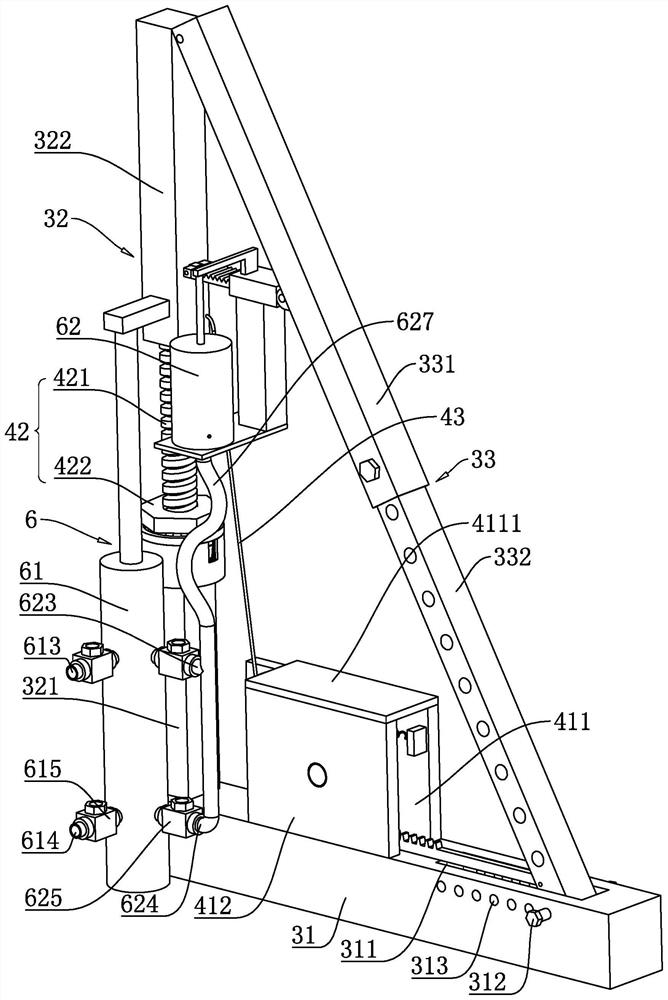

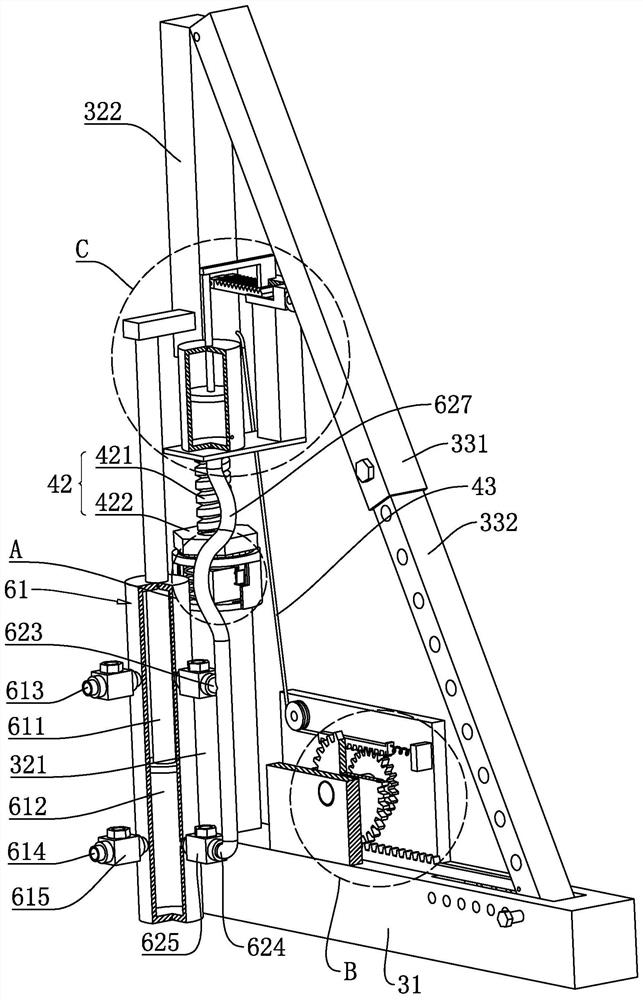

[0049] Attached to the following Figure 1-6 This application will be described in further detail.

[0050] The embodiment of the present application discloses a self-stabilizing assembled formwork support system. refer to figure 1 , a self-stabilizing assembled formwork support system, comprising a formwork 2 and a triangular truss body 3, the formwork 2 and the wall 1 are fitted and arranged, and the triangular truss body 3 includes a truss vertical rod 32, a truss diagonal rod 33 and a truss connected end-to-end Bottom bar 31. The truss vertical rod 32 is attached to the side of the formwork 2 away from the wall 1, the truss diagonal rod 33 is hinged with the truss vertical rod 32, the truss bottom rod 31 is fixed on the ground, and the truss bottom rod 31 slides with the ends of the truss diagonal rod 33 connect. A vertical and horizontal adjustment device 4 is arranged on the triangular truss 3. The vertical and horizontal adjustment device 4 includes a height adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com