Timepiece assembly and manufacturing method thereof

A technology for components, timepieces, used in the field of balance wheels and inertia screws, to manufacture said components, able to solve problems such as stress corrosion of the underlying material, damage to bearing or gripping areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

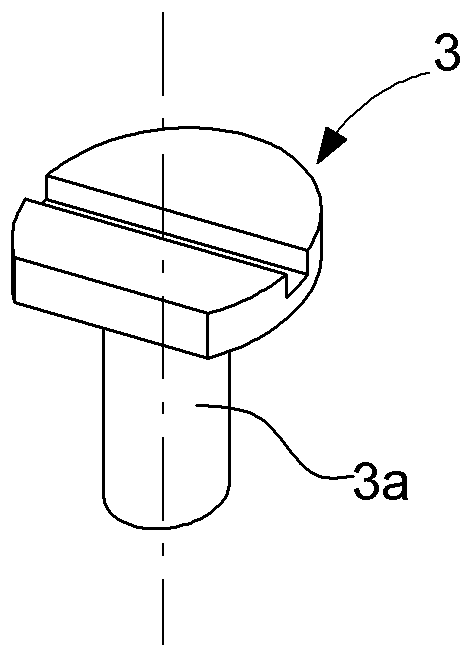

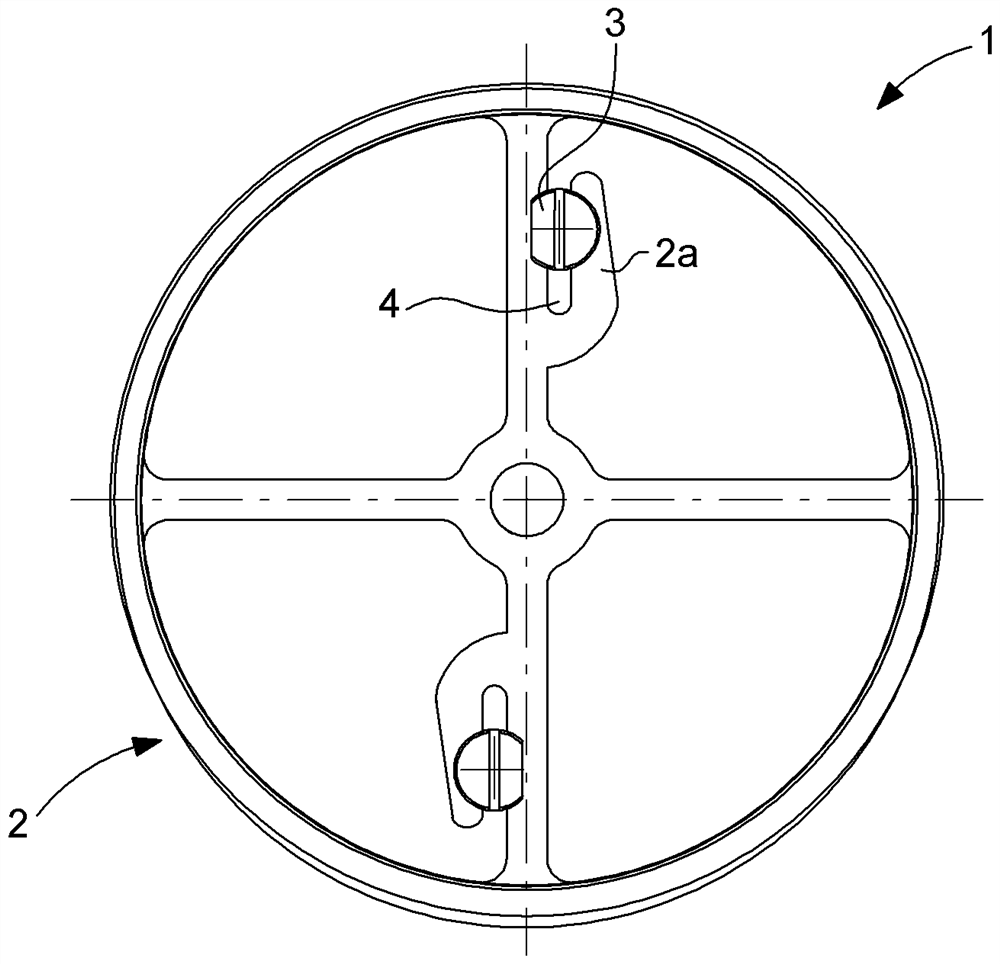

[0014] The invention relates to a timepiece assembly comprising at least two parts assembled under stress. By way of example, as figure 1 , the first part is the balance wheel 2, which includes an elastic arm 2a defining a slot 4 that receives the second part during assembly, the second part being in figure 2 Inertia screw 3 is also visible. It can also be a pressed-in element, such as a shock pin in a plateau or a balance wheel on an axle, etc.

[0015] The components may be made from a material selected from the list including copper, copper alloys such as brass or cupronickel, aluminum, aluminum alloys, titanium, titanium alloys, carbon steel, and ferritic and austenitic stainless steels.

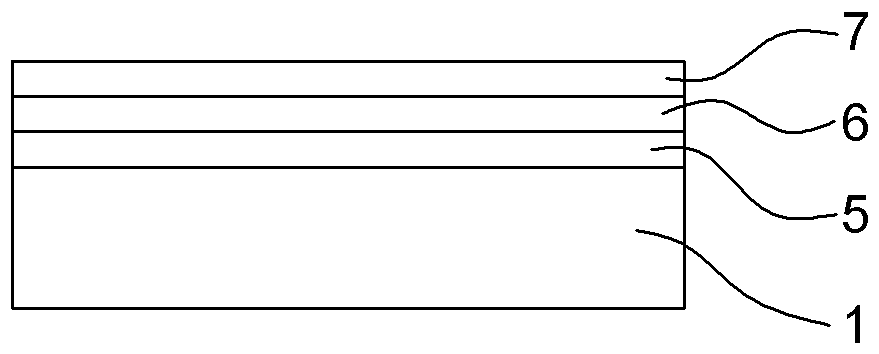

[0016] According to the invention, the timepiece assembly is at least partially coated after assembly with a protective layer intended to cover any defects, such as cracks, incipient cracks, peeling, caused by the assembly process or which may have existed before assembly. Figure 4A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com