Quality monitoring method and monitoring system for false-twisted yarn

A quality monitoring and monitoring system technology, applied in the field of textile false-twisted yarn quality monitoring, can solve problems such as inability to monitor in real time, achieve the effects of timely spindle stop, reduce defective rate, and monitor quality accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

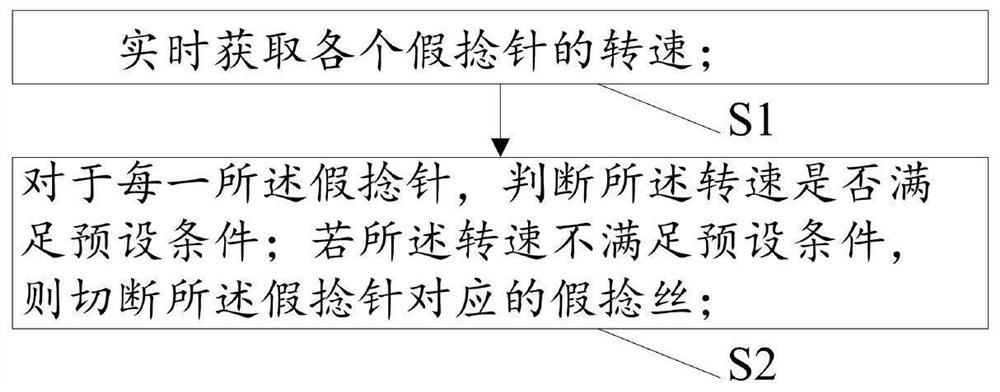

[0025] This embodiment is used to provide a kind of quality monitoring method of false twist yarn, as figure 1 Shown, described monitoring method comprises the steps:

[0026] S1: Obtain the speed of each false twisting needle in real time;

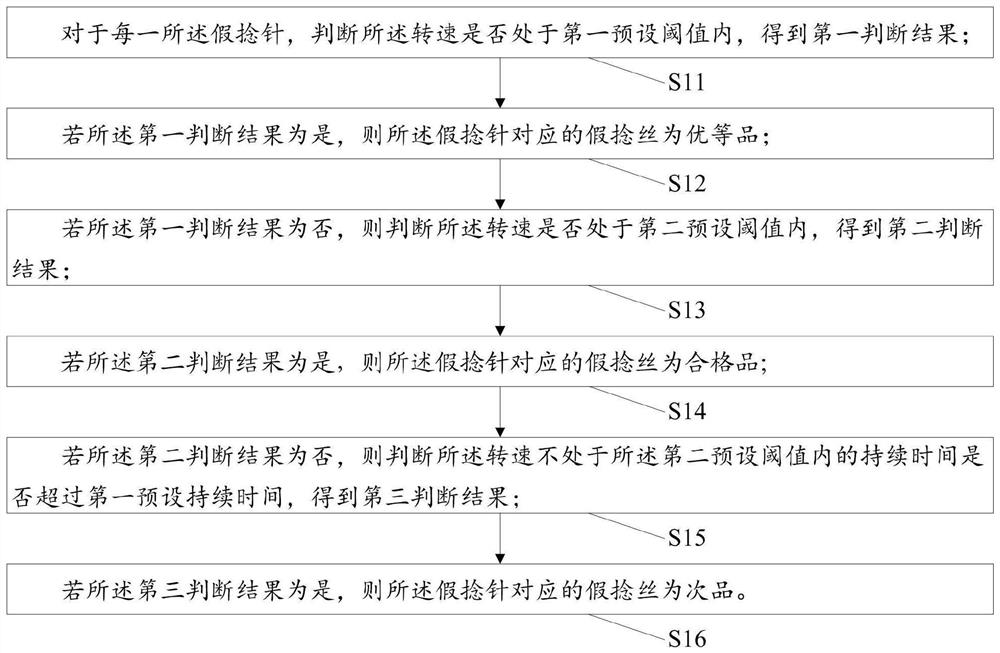

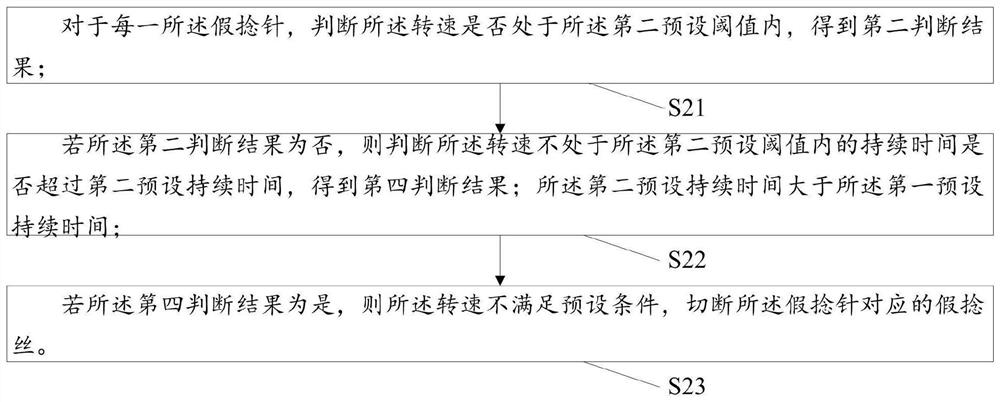

[0027] Since there is a certain correspondence between the twist of the false twisted yarn and the rotational speed of the false twisting needle, the twist value of the false twisted yarn can be calculated according to the rotational speed of the false twisting needle through table lookup and correction coefficient, and then the quality of the false twisted yarn can be obtained. Therefore, after acquiring the rotating speeds of each false twisting needle in real time, the monitoring method of this embodiment also includes judging the quality of the false twisting yarn corresponding to the false twisting needle, such as figure 2 As shown, specific steps may include:

[0028] S11: For each of the false twisting needles, judge whether the...

Embodiment 2

[0044] This embodiment is used to provide a quality monitoring system of false twisted yarn, such as Figure 4 As shown, the monitoring system includes:

[0045] The rotational speed sensor 1 is used to collect the rotational speed signals of each false twisting needle in real time. The rotational speed sensor 1 is fixedly installed near the false twisting needle through a bracket, and the rotational speed sensor 1 can be a photoelectric sensor or a Hall sensor, and the rotational speed sensor 1 can accurately detect the rotational speed signal of the false twisting needle. A monitoring system can include multiple speed sensors 1 at the same time, and can monitor the quality of multiple spindles of false twisted yarn at the same time, greatly saving labor costs.

[0046] The central display control unit 2 is communicatively connected with the rotational speed sensor 1, and is used to judge whether the rotational speed corresponding to the rotational speed signal satisfies the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com