Method and device for in situ process monitoring

A process monitoring and in-situ technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of tedious calculation and data analysis, impossible and limited continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

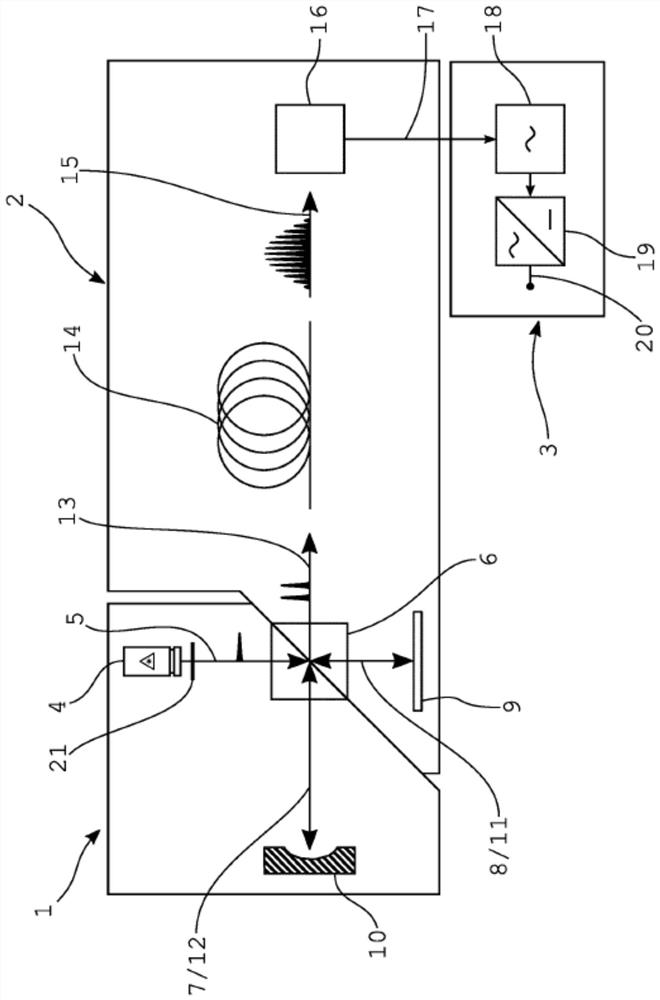

[0054] figure 1 The overall operation of the invention is provided and key elements of a method for enabling in situ process monitoring during laser processing and / or ablation are shown. A technical implementation of this method is also shown.

[0055] In principle, the overall application consists of three parts: material handling unit 1, measurement unit 2 and control unit 3.

[0056] The material handling unit 1 provides an operating beam which processes a target object 10 . An ultrashort pulse laser beam 5 is emitted by an ultrashort pulse laser 4 .

[0057] The ultrashort pulse laser 4 can emit pulses at a pulse interval which is longer than the duration of the tensile measurement signal of the interference beam 15 . In this case, the pulse interval is in the range of about 1 ns to 20 ns.

[0058] In another embodiment, the ultrashort pulse laser 4 emits equidistant laser pulses.

[0059] In one advantageous application, the pulse duration is in the range of nanoseco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com