Actively-driven ankle joint artificial limb

An active drive, ankle joint technology, applied in the field of prosthetics, can solve the problems of complex, high cost and large volume of active ankle joints, and achieve the effects of light weight, light use and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

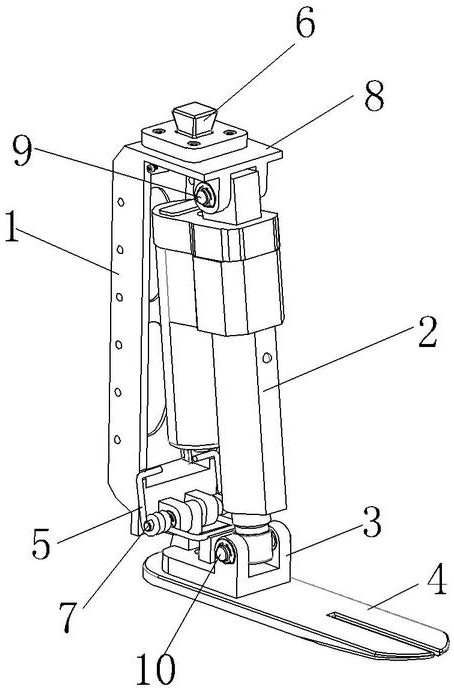

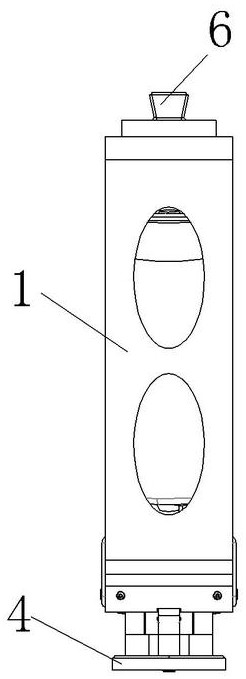

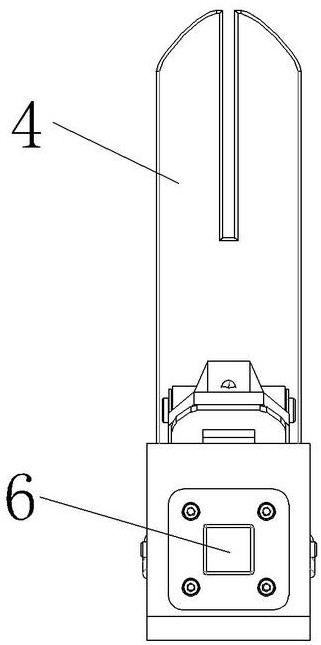

[0019] see Figure 1 to Figure 8 As shown, an actively driven ankle joint prosthesis includes a main frame 1, an electric linear driver 2, a foot plate connecting frame 3, a foot plate 4, a torsion spring 5 and a square platform 6; the foot plate connecting frame 3 is fixed on the upper surface of the foot plate 4 The bottom of the main frame 1 is hinged with the rear end of the foot plate connecting frame 3 through the ankle joint rotating shaft 7, the top of the main frame 1 extends forward with a platform 8, and a square platform 6 is installed on the platform 8, and the square platform 6 is used for Connected with the leg structure; the top of the electric linear driver 2 is hinged with the front lower part of the platform 8 through the first rotating shaft 9, and the lower end of the electric linear driver 2 is hinged with the front of the foot plate connecting frame 3 through the second rotating shaft 10; the ankle joint The rotating shaft 7 is sleeved with a torsion spr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap