Automatic detection system for surface defects of workpieces

A workpiece surface, automatic detection technology, applied in sorting and other directions, can solve the problems of high manual detection cost and insufficient automation level, and achieve the effect of avoiding errors, fully automation, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

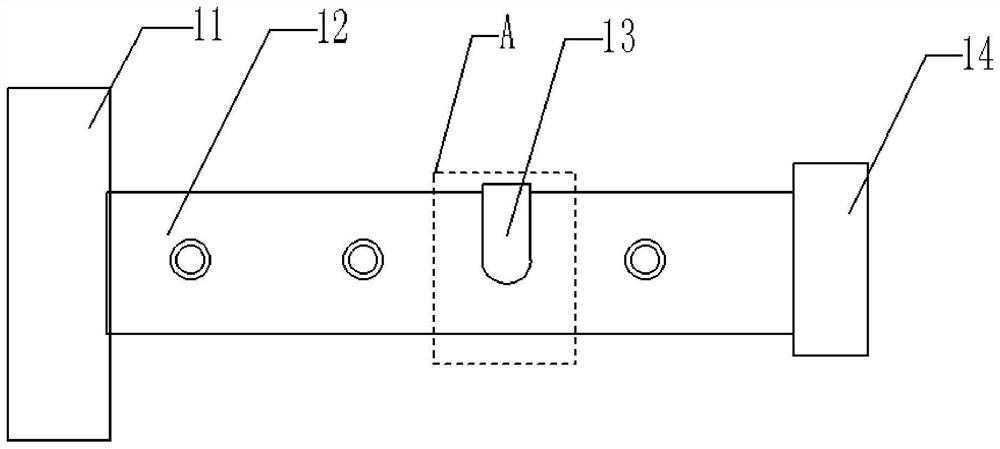

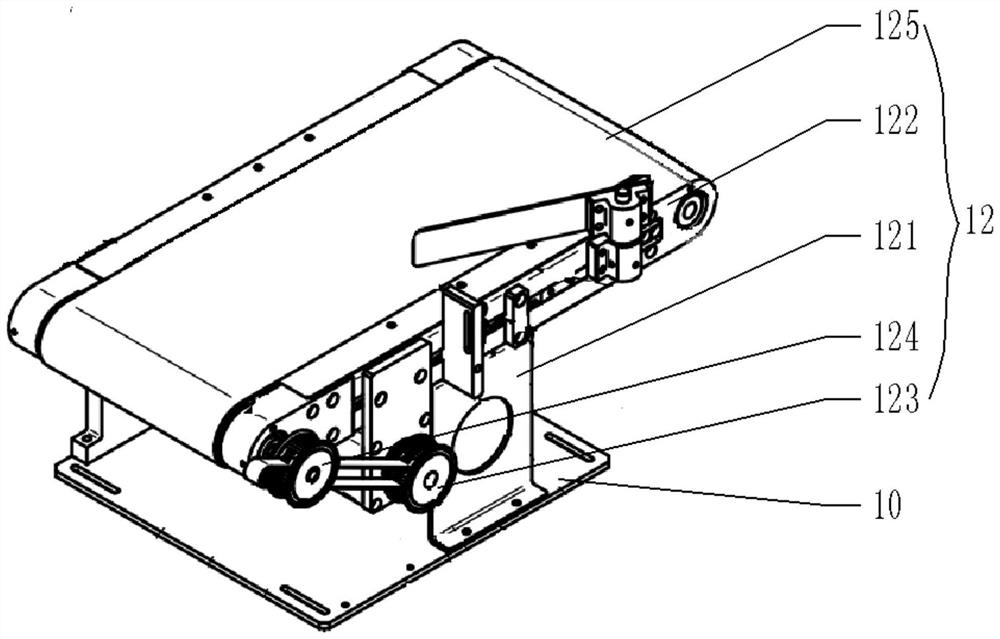

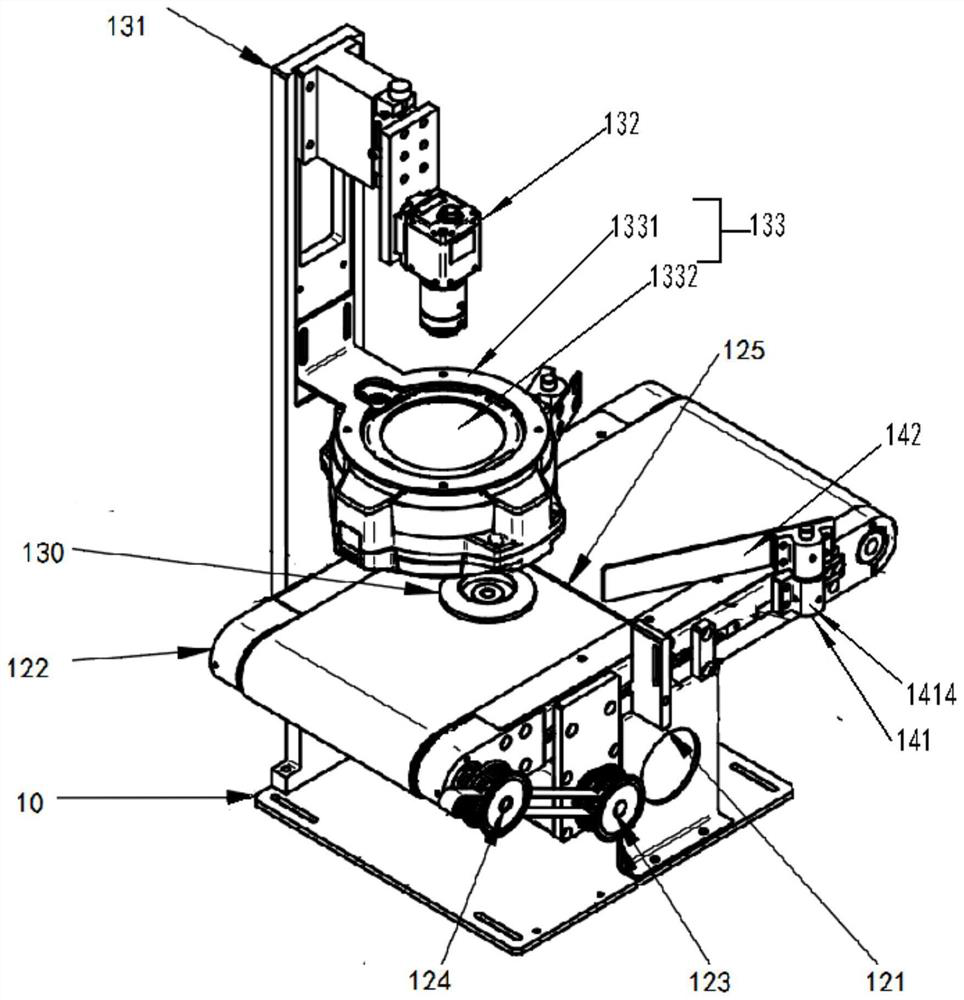

[0047] Such as figure 1As shown, the present invention provides an automatic detection system for workpiece surface defects, which includes a feeding device 11 , a conveying device 12 , an automatic detection device 13 and a sorting device 14 . The feeding device 11 is used for vibrating feeding, and the workpiece is placed on the transmission start end of the transmission device 12; the transmission device 12 is used to transmit the workpiece placed by the feeding device 11 from the transmission start end to the transmission end, And through to the preset area A corresponding to the automatic detection device 13, the preset area A is a preset fixed area on the transmission device 12; the automatic detection device 13 is located above the transmission device 12 for When the workpiece conveyed on the conveying device 12 reaches the preset area A, the workpiece surface flaws are automatically detected on the workpiece, and the defect detection result information is output; the s...

no. 2 approach

[0094] The second embodiment of the present invention provides an automatic detection system for workpiece surface blemishes, such as Figure 6 As shown, the automatic detection system for workpiece surface defects includes a feeding device 21, a first transmission device 22, a first automatic detection device 23, a turning device 24, a second transmission device 25, a second automatic detection device 26 and a sorting device 27 .

[0095] Wherein the structure of the feeding device 21 is the same as that of the first embodiment, the first conveying device 22 is used to transport the workpiece from the conveying starting end (left end) to the conveying end (right end), and the second conveying device 25 is used for The workpiece is transported from the transmission starting end (right end) to the transmission end (left end), the first transmission device 22 is provided with a first preset area A, and the second transmission device 25 is provided with a second preset area B; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com