Ink printing method for outer surface of bottle body

An ink printing and outer surface technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of insufficient printing, decreased printing quality, large printing difficulty, etc., to improve printing efficiency, reduce printing difficulty, and shorten the cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

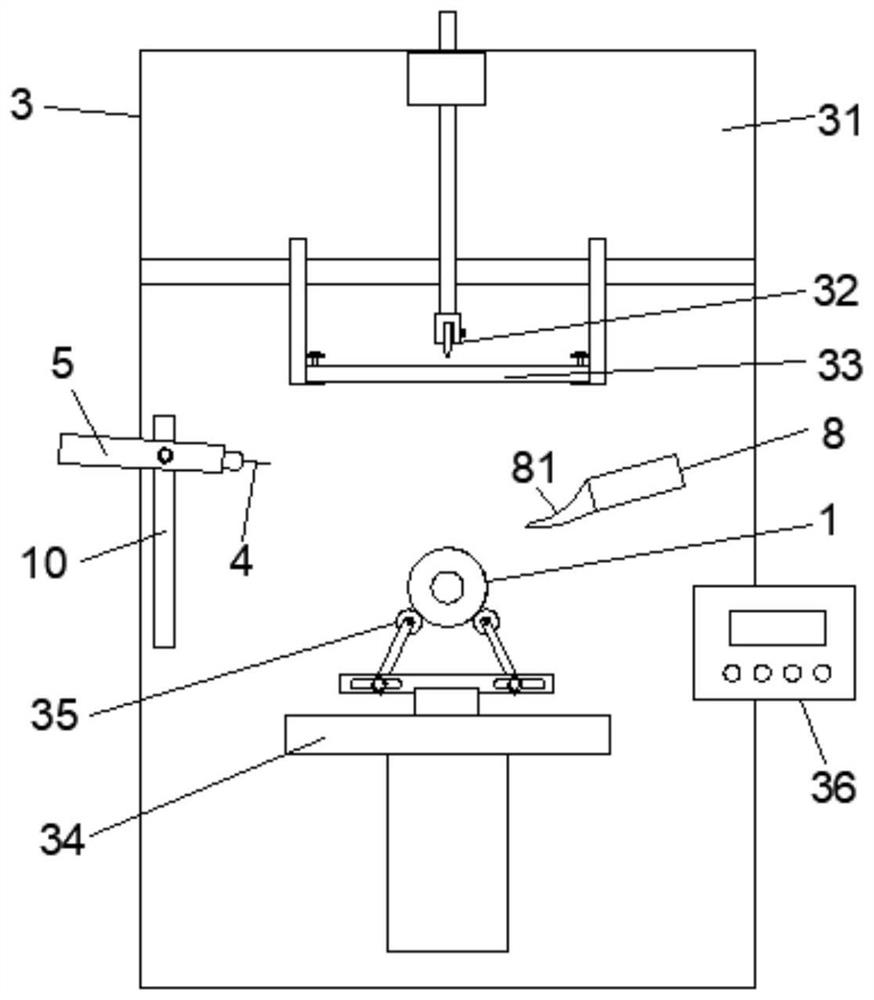

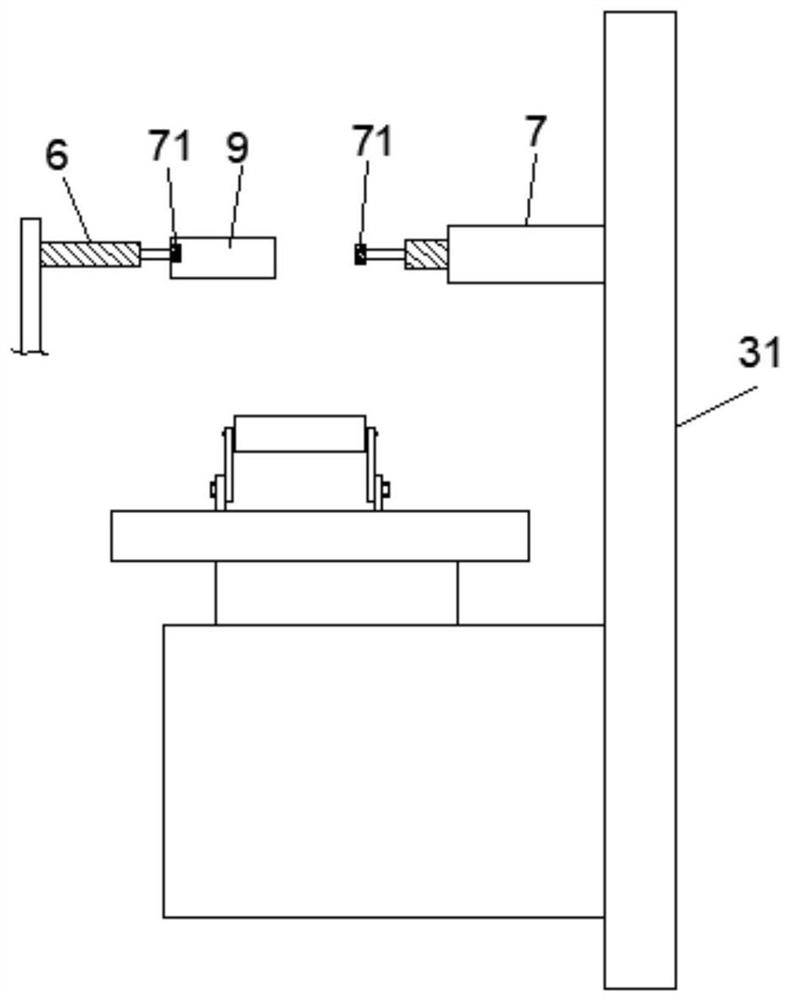

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] Refer to attached Figure 1-12 Shown, a kind of ink printing method to bottle outer surface, described method is used for bottle body 1 outer surface simultaneously has the printing body of multiple printing colors to carry out batch and continuous printing operation, and it comprises the following steps:

[0040] Step 1, reference plane printing, which includes the following processes:

[0041] a. Positioning: place the bottle body 1 with the printing paper 2 on the surface on the monochrome printing machine 3, and perform the first positioning of the reference plane printing on the bottle body 1. Wherein, the reference plane is defined as the ink printing surface occupied by fonts or patterns of the same c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com