Pipe burying device based on hard land in water conservancy project

A water conservancy project, hard technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of low positioning accuracy and lack of water pipelines, so as to improve the positioning accuracy of operations, avoid internal blockage, and high construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1: See Figure 1 - Figure 6 The present invention is specifically implemented, for example:

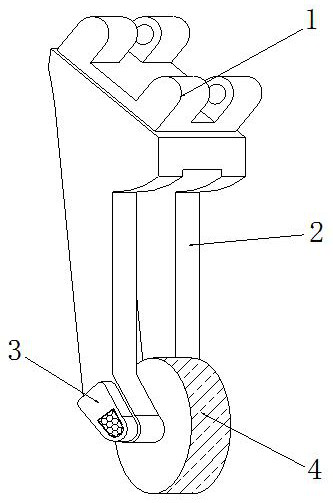

[0027] The present invention provides a bubble device based on hard land in a water conservancy engine, including a hinge block 1, a connecting frame 2, a motor box 3, a tank device 4, and the hinge block 1 is provided on the upper end of the connecting frame 2, and The hinge block 1 is integrated with the connecting frame 2, and an electric machine is disposed inside the motor box 3, the motor box 3 mounted on the left end of the connecting frame 2, the tank device 4 acting engaged in the inner wall of the connecting frame 2.

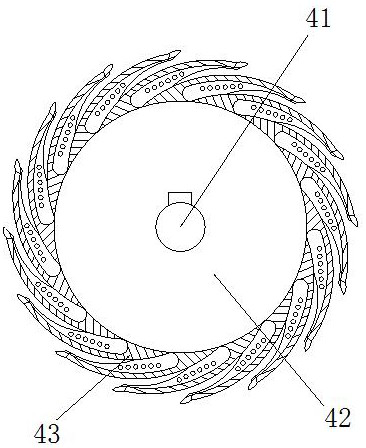

[0028] The tank device 4 is composed of a rotating shaft 41, a turntable 42, a cutter 43, and the rotating shaft 41 is actively engaged in the middle of the turntable 42, the rotating shaft 41 is connected to the motor strip provided in the motor box 3, the digging knife 43 There are a total of sixteen, and the sixteen of the cutter 43 is uniformly w...

Example Embodiment

[0034] Example 2: See Figure 7 - Figure 8 The present invention is specifically implemented, for example:

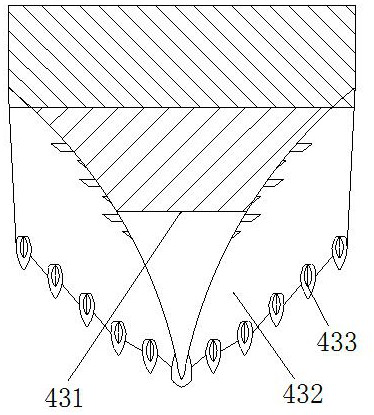

[0035] The present invention provides a buried tube device based on hard land in a water conservancy engine, which is composed of a tapered 331, a broken hammer 332, and a guiding angle 333, and the welding connection of the cone 331 has a broken sole hammer 332. The angle of the guide angle 333 is 70 degrees, and the conductive angle 333 is provided inside the cone 331, and the guiding angle 333 and the taper 331 are integrated structures, and the angle is 70-degree guiding angles 333. Easy to move the earth block to the outside.

[0036]The cutheme 332 is composed of a block 321, a pendulum 322, a fixed shaft 323, a first hammer head 324, and a second hammer head 325, and the lower end of the pendulum 322 is engaged inside the block 321 through the fixed shaft 323. The first hammer head 324 is a semi-circular spherical structure, and the first hammer head 324 is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com