Integrally-cast parallelly-hung integrated wallboard and quick installing type wall structure thereof

A technology that integrates wall panels and wall structures, applied to walls, building components, building structures, etc., to achieve the effects of high construction precision, rapid non-destructive disassembly, and rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

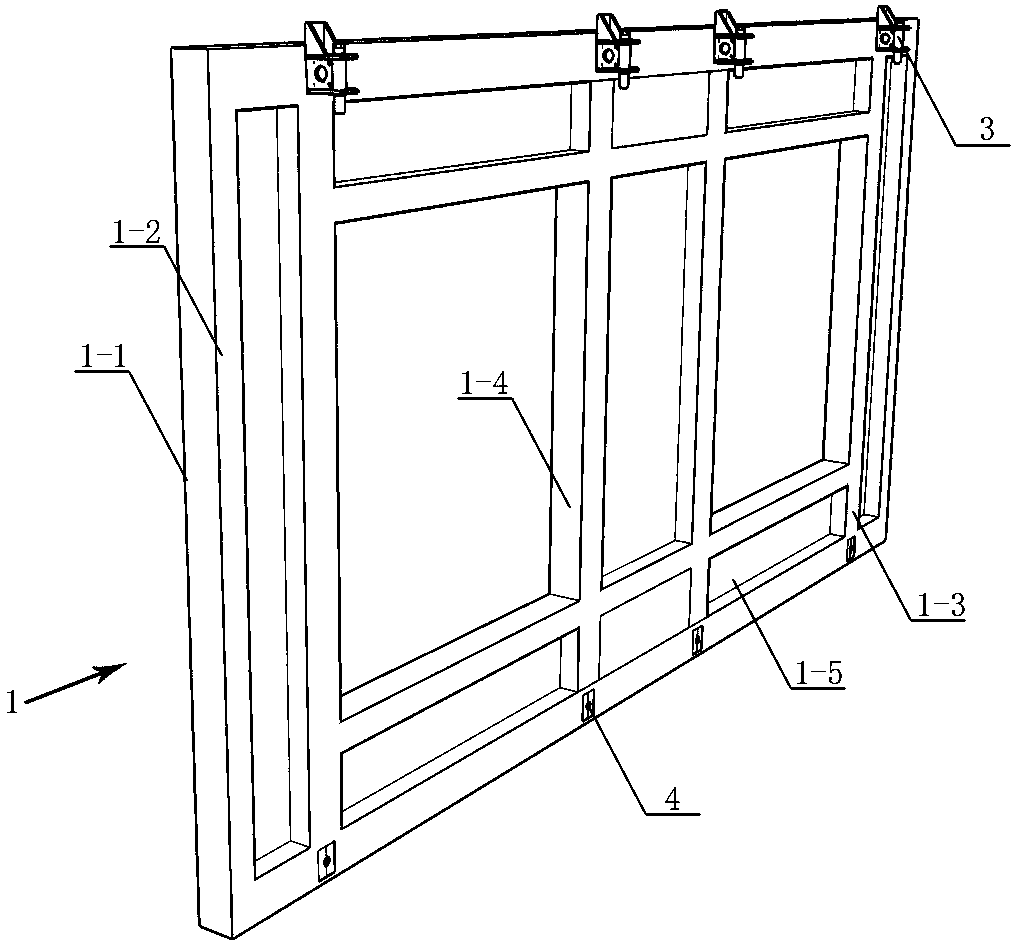

[0046] Examples see figure 1 As shown, the integral cast and hang integrated wall panel 1 is a prefabricated concrete component, at least two parallel hanging parts 3 are pre-embedded in the upper part, and at least two butt joint parts 4 are pre-embedded in the lower part.

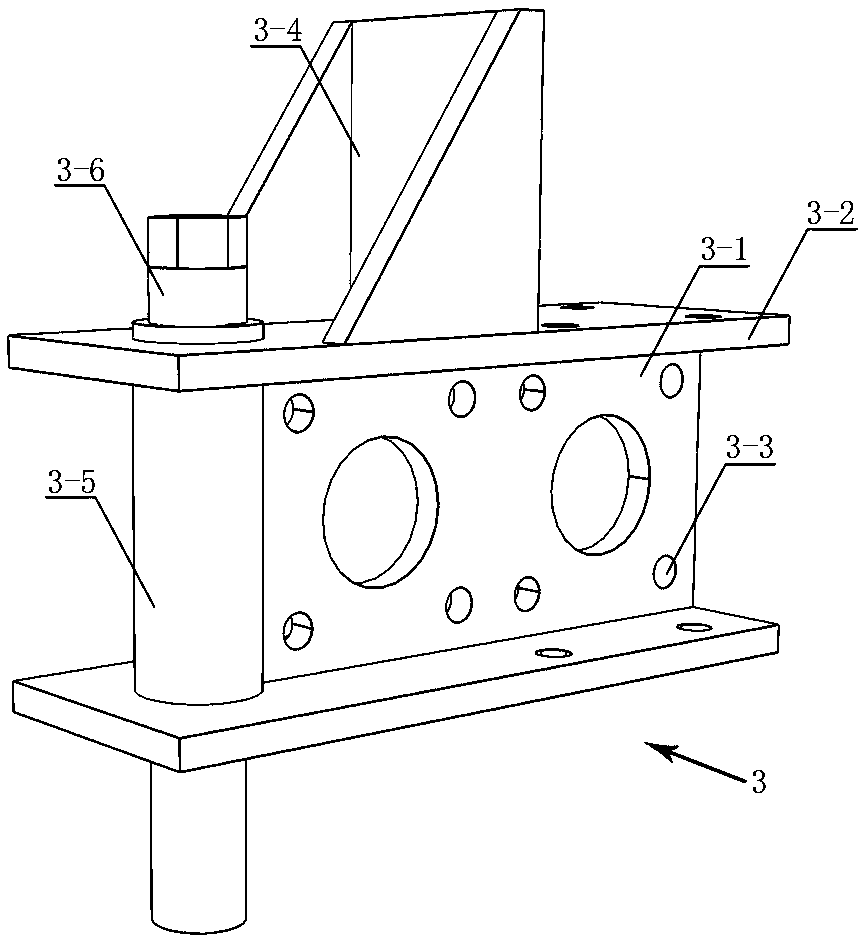

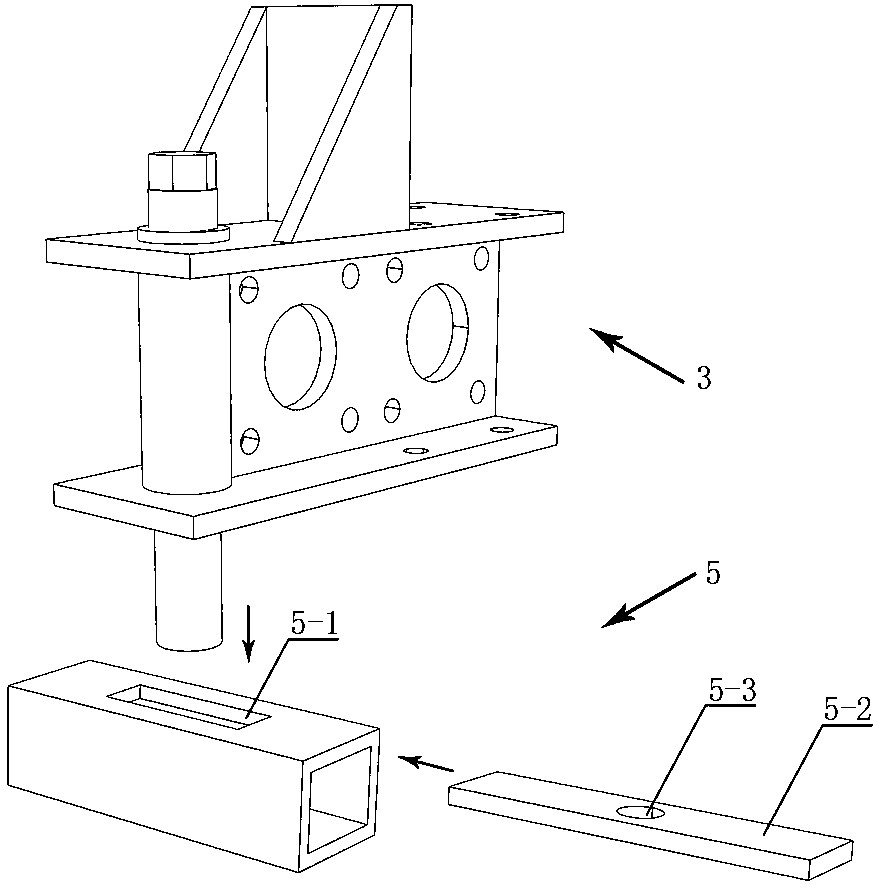

[0047] see figure 2 As shown, the parallel hanger 3 is an H-shaped, T-shaped or square tubular steel embedded part with a transverse parallel flange and a vertical vertical web; the parallel hanger 3-2 There is a connecting plate 3-4 in the middle of the upper surface; the inner end of the connecting part is embedded in the concrete of the wall board, and the outer end protrudes vertically from the inner surface of the integrated wall board; the web 3-1 of the connecting part at the inner end and the The pendant wing plates 3-2 are respectively provided with parallel pendant piercing rib holes 3-3; the parallel pendant penetrating rib holes 3-3 are space dislocation holes; see Figure 6 As shown, horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com