Drainage pipe, manufacturing method thereof and drainage pipe unit assembly method

A manufacturing method and technology for drainage pipes, which are applied to water supply devices, sewer pipe systems, waterway systems, etc., can solve problems such as troublesome disassembly operations, reduce construction efficiency, and consume time, and achieve simple assembly or disassembly, excellent construction efficiency, and construction efficiency. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

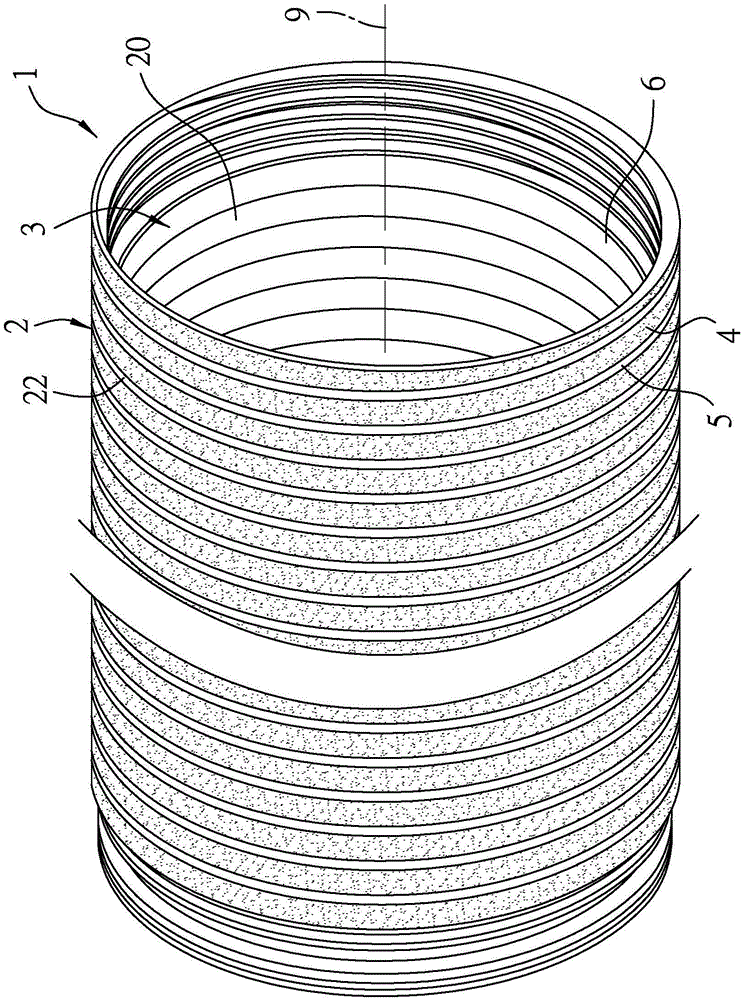

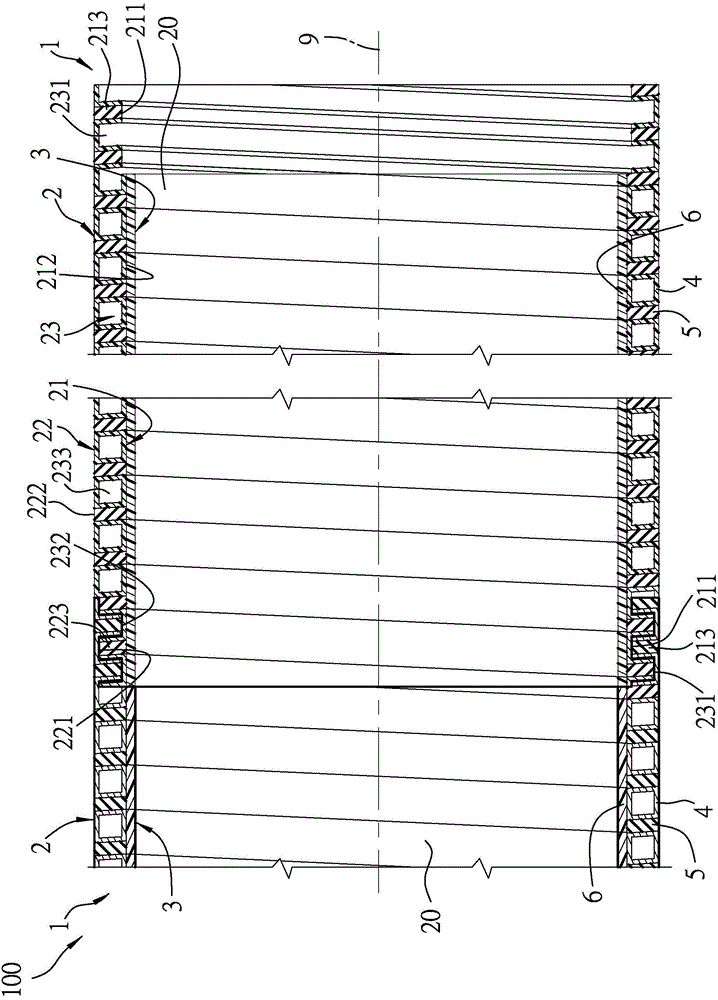

[0030] refer to figure 1 , 2 , 3, a preferred embodiment of the drainpipe 1 of the present invention can be assembled together in a detachable manner in several groups to communicate with each other, thereby forming a drainpipe unit 100, and is suitable for being installed under the ground for general drainage Pipes, for example, are used to collect domestic sewage or industrial waste water so that it can be collected and sent to a sewage treatment plant. The drain pipe 1 includes a pipe wall 2 and a reinforcing wall 3 disposed inside the pipe wall 2 .

[0031] The tube wall 2 of the present embodiment includes an inner tube surface 21 that defines a drainage channel 20 around a central axis 9, an outer tube surface 22 spaced from the inner tube su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com