Reinforcing structure for non-flush joints of outer vertical face of concrete frame structure

A frame structure and reinforcement structure technology, which is applied in the direction of building construction, construction, building maintenance, etc., can solve the problems of automatic reinforcement, no clamping position, and inability to assist cross-bar connection, etc., to achieve enhanced fixing effect and stable fixed installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

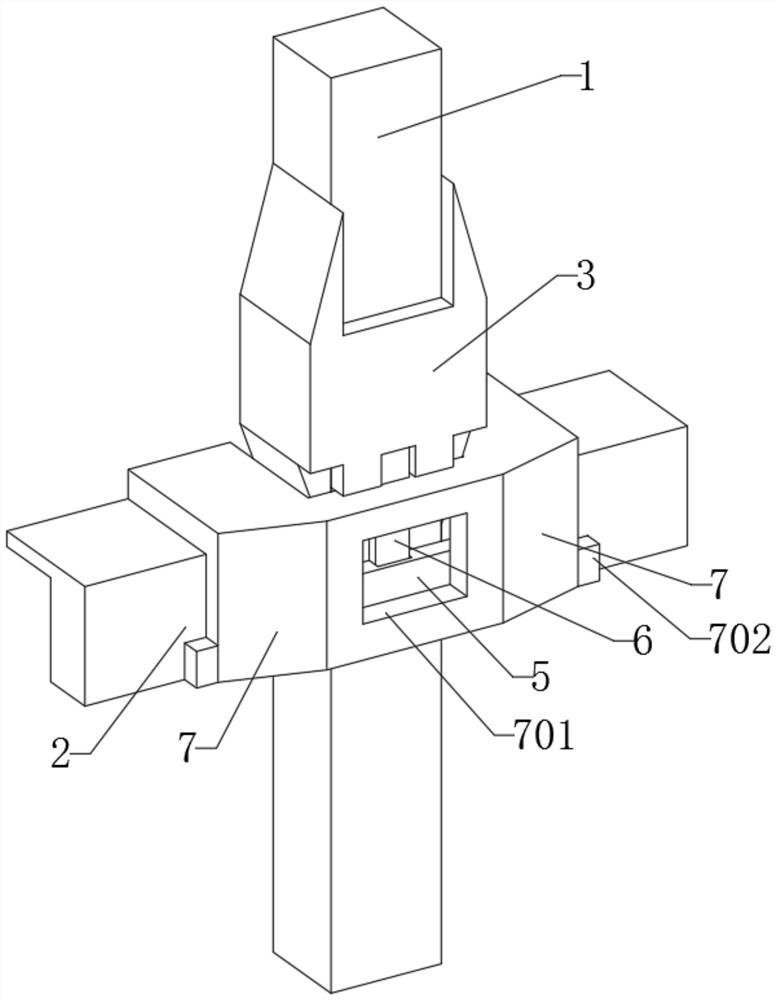

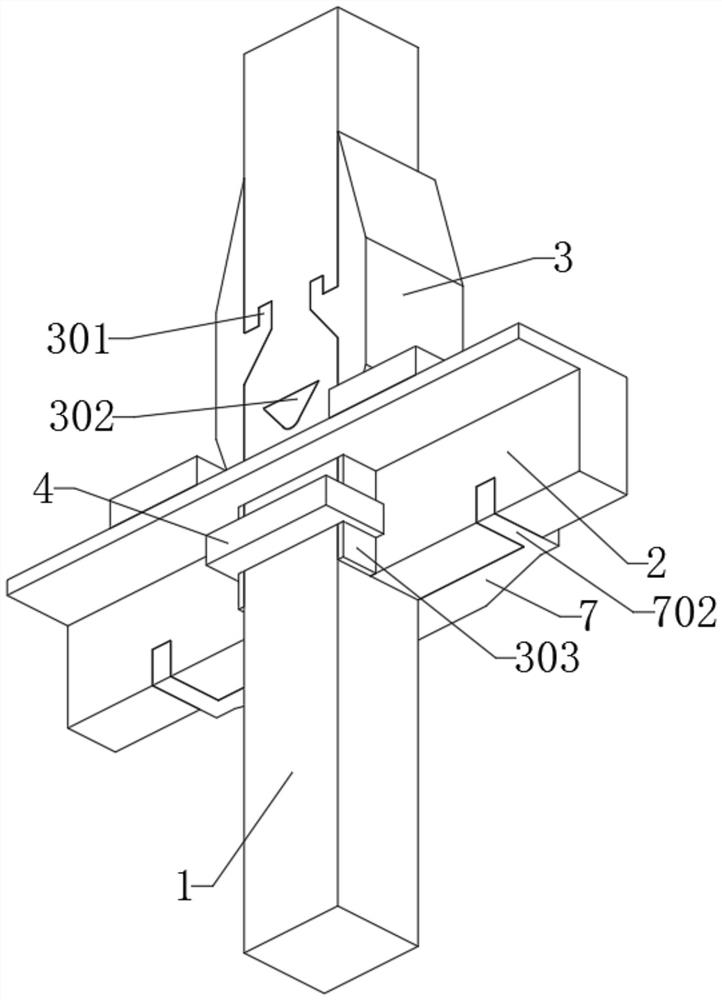

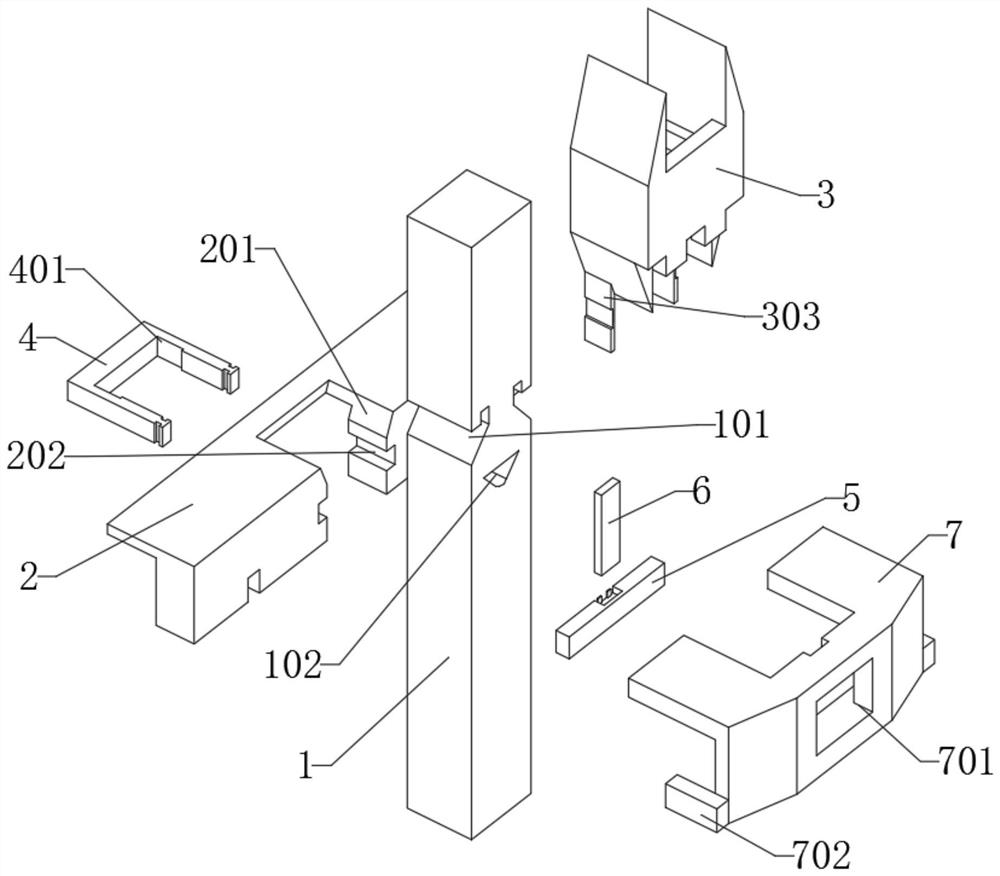

[0034] like Figure 1-Figure 8 As shown, the present invention is used for the reinforced structure of uneven joints on the facade of concrete frame structure, which is composed of main body 1, beam 2, force-bearing member 3, connector 4, fixing plate 5, control plate 6 and reinforcing member 7.

[0035] The main body 1 is a rectangular strip structure made of concrete material, and the main body 1 is embedded in the installation groove 201 of the beam 2 . The connecting piece 4 is inserted and installed inside the fixing groove 202 of the crossbeam 2 , at the middle position outside the connecting plate 303 of the force receiving member 3 . The top of the control board 6 is inserted into the rectangular groove of the force receiving member 3 , the bottom is inserted into the inner groove 502 of the fixed plate 5 , and a rectangular board is inserted into the control groove 601 of the control board 6 . The reinforcing piece 7 is set on the front end of the crossbeam 2 , the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com