Low-sliding-rate gear and design method thereof

A slip rate and gear technology, applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of easy wear and high gear slip rate, reduce wear, improve bearing capacity, and optimize lubrication conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to clearly illustrate the technical characteristics of this patent, the present patent will be described in detail below by the specific embodiments and combined with the drawings.

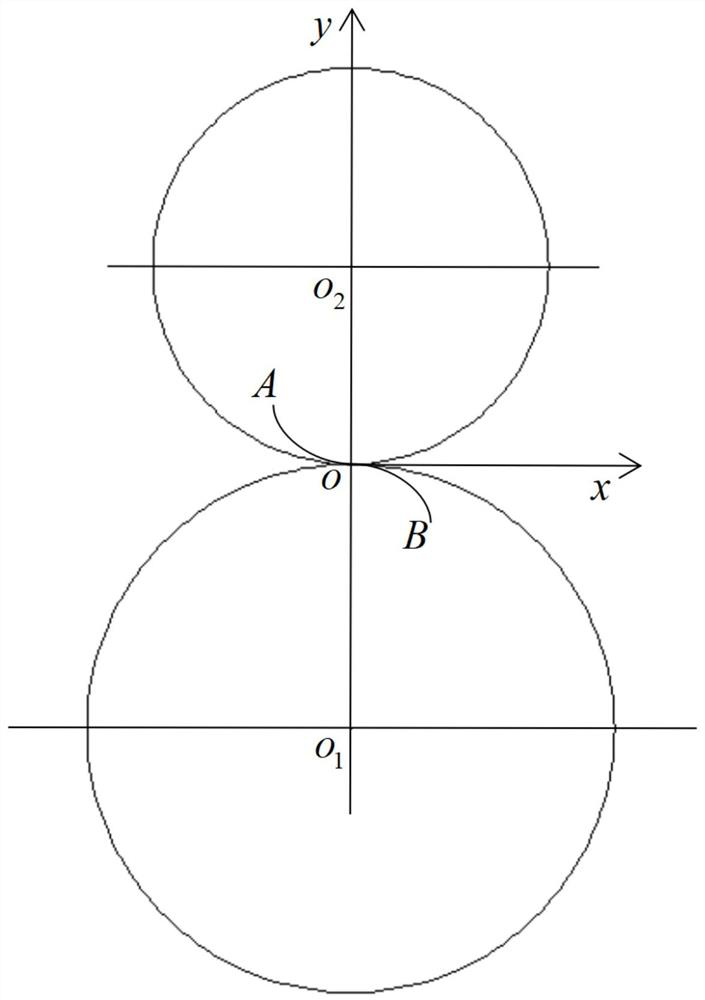

[0029] According to the present invention Figure 1-4 As shown, the low sliding rate gear provided by the present invention is used to design the production of the low slider gear tooth profile to be obtained by establishing a meshing path curve that enables a gear sub-low slide rate. AB equation (in figure 1 The coordinate system XOY is:

[0030] y = a 1 X + a 2 x 3

[0031] Among them, A 1 , A 2 For the general coefficient, X is the argument of the equation, the coordinate is the original point O in the node position, the X axis is a circular criterion, the Y-axis passes two gears 1 , O 2 .

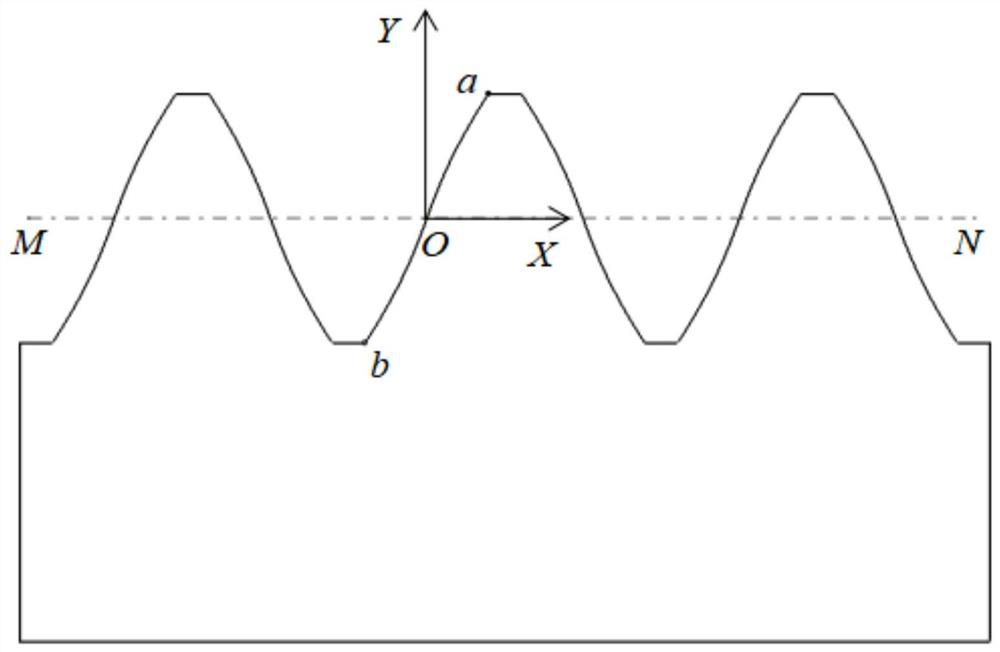

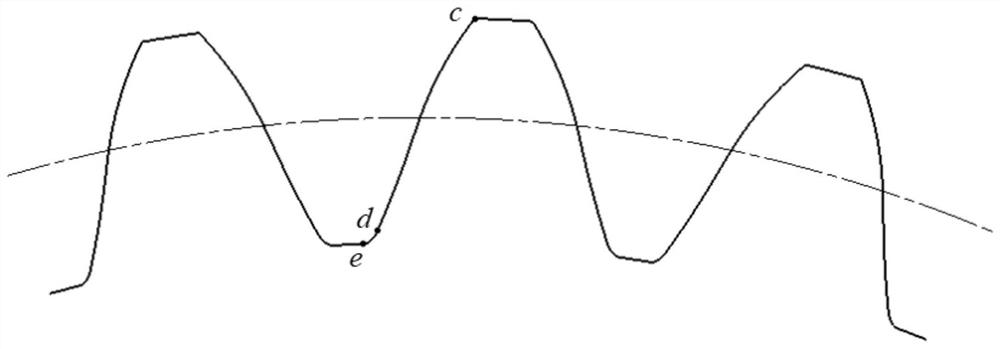

[0032] The low sliding rate gear tooth provided by the present invention is obtained by a low slider, and the rack of the rack of the low slide is obtained, and the rack of the rack of the low s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com