A kind of low slip rate gear and its design method

A sliding rate and gear technology, applied in the direction of belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of easy wear and high sliding rate of gears, reduce wear, increase bearing capacity, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

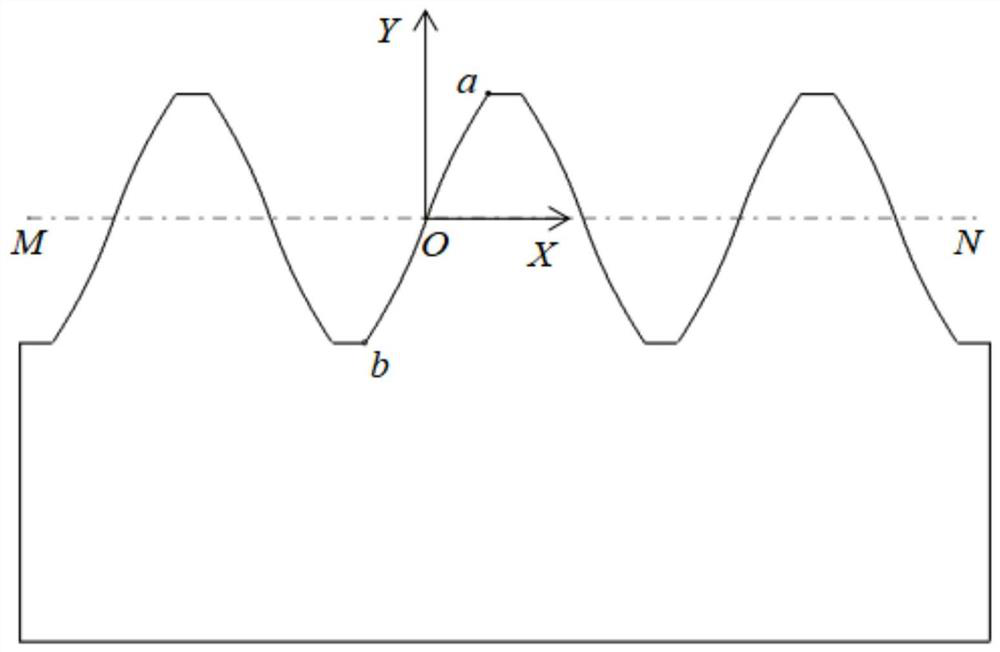

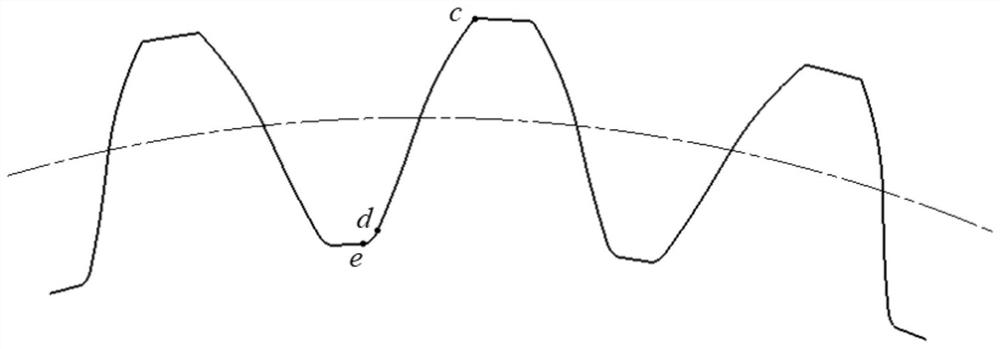

[0028] In order to clearly illustrate the technical features of the present patent, the present patent will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

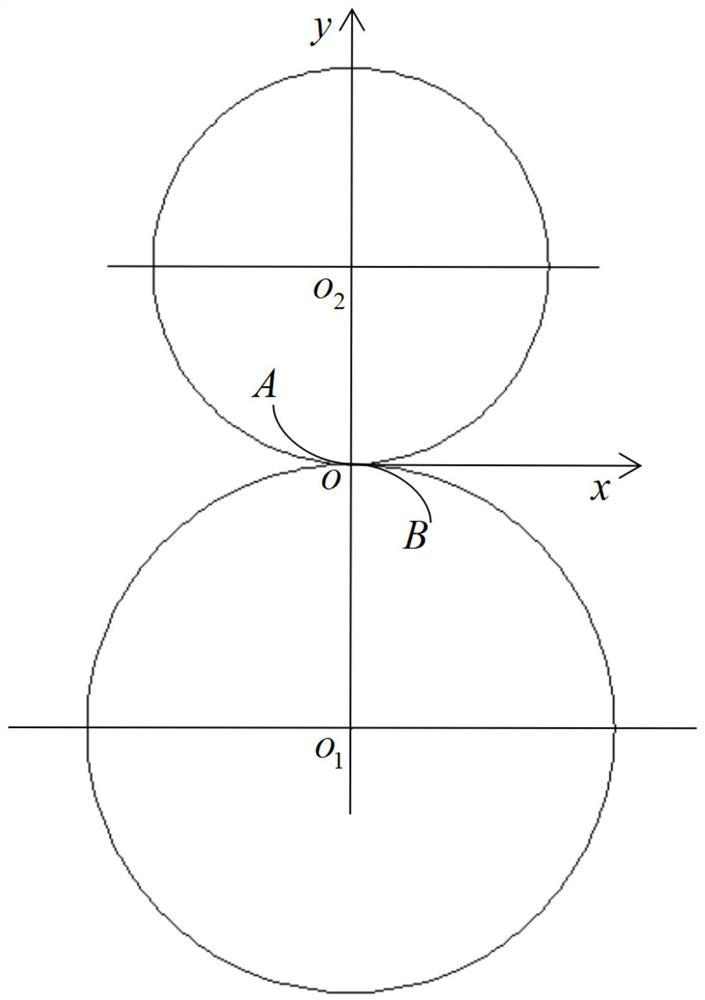

[0029] The present invention is as Figure 1-4 As shown, in the low-slip ratio gear provided by the present invention, the shaped rack used for designing the tooth profile of the low-slip ratio gear is obtained by establishing a meshing path curve that can realize a low slip ratio of the gear pair, and the meshing path curve AB equation (in figure 1 in the coordinate system xoy) is:

[0030] y=a 1 x+a 2 x 3

[0031] Among them, a 1 , a 2 is the general coefficient, x is the independent variable of the equation, the origin o of the coordinate system is at the node position, the x-axis is the common tangent of the pitch circle, and the y-axis passes through the center of the two gears o 1 , o 2 .

[0032] The low-slip rate gear tooth profile provided by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com