Local color change type numerical control bending machine product crack detection device

A detection device and machine-made technology, which is applied in the direction of optical detection of defects/defects, etc., can solve the problems of lower detection efficiency, outer wall cracks, fractures, etc., and achieve the effect of improving detection efficiency and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

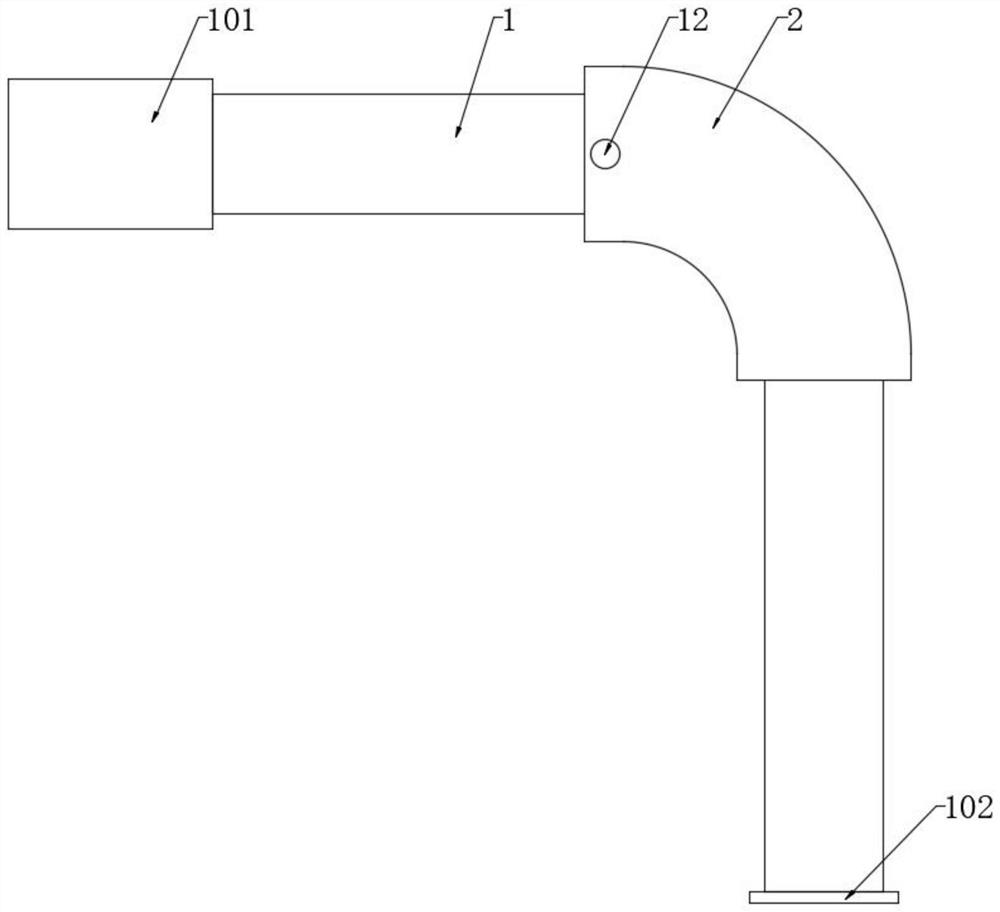

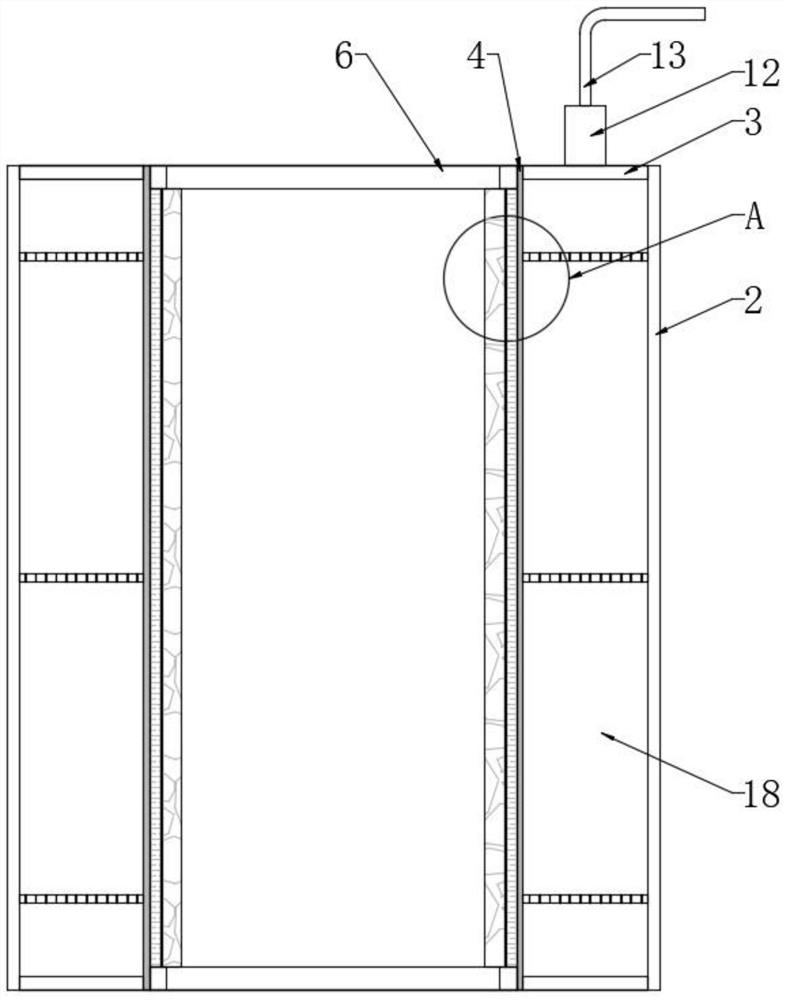

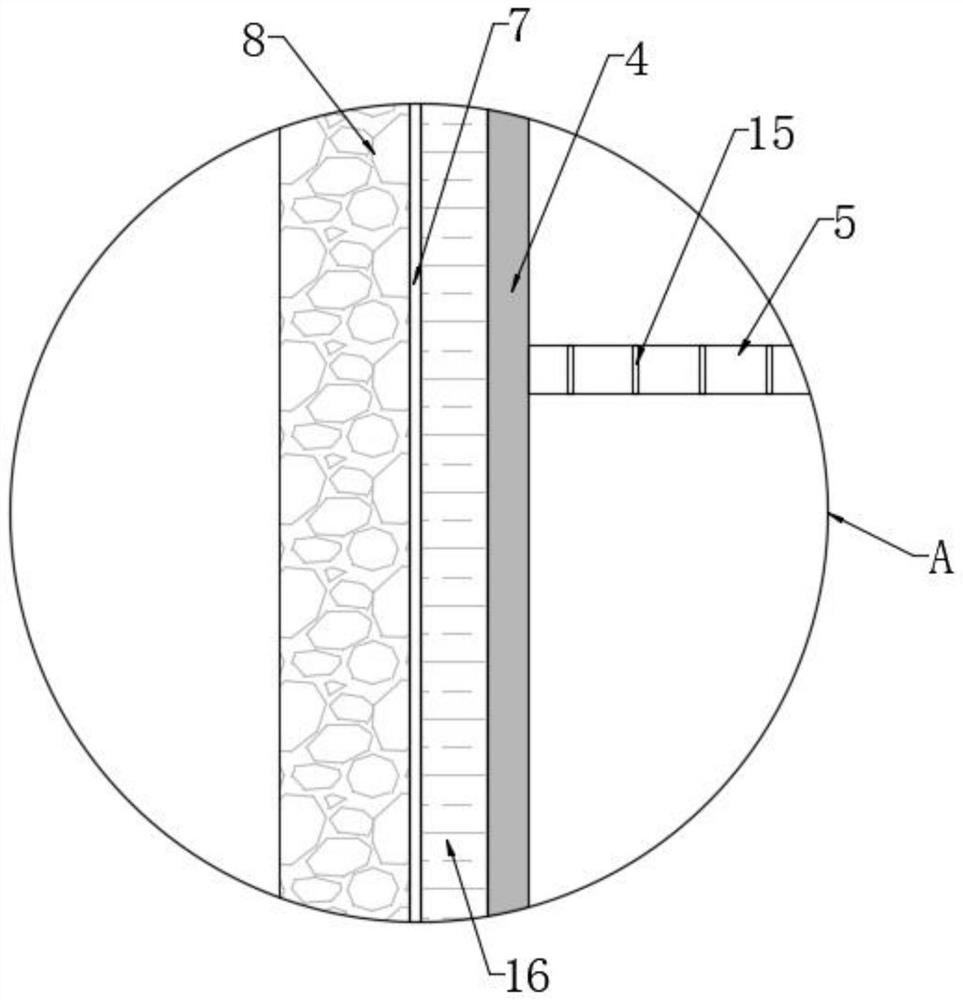

[0043] see Figure 1-6, a crack detection device for local color-changing CNC bending machine products, including a detection workpiece 1, a fan 101 and a sealing sheet 102 installed on the detection workpiece 1, a detection sleeve 2 is set on the detection workpiece 1, and a detection sleeve The upper and lower ends of the tube 2 are fixedly connected with an elastic connecting film 3, and the two elastic connecting films 3 are fixedly connected with the same gas-permeable film 4 on the side wall away from the detection sleeve 2, and the gas-permeable film 4 is fixedly connected with the detection sleeve 2. A plurality of evenly distributed elastic expansion lines 5, the upper and lower ends of the breathable membrane 4 are fixedly connected with a sealing ring 6, between the two sealing rings 6 is fixedly connected with a breathable membrane 7, and the inner wall of the breathable membrane 7 is fixedly connected with a smear cotton 8, Breathable membrane 7 is bonded with sme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com