Discrete optimization method based on matrix workshop AGV scheduling

An optimization method, discrete technology, applied in the direction of control/regulation system, comprehensive factory control, instruments, etc., can solve the problems of not reducing transportation cost, low number of iterations, and inability to obtain, so as to reduce transportation cost and reduce calculation time. , the effect of increasing the number of iterations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

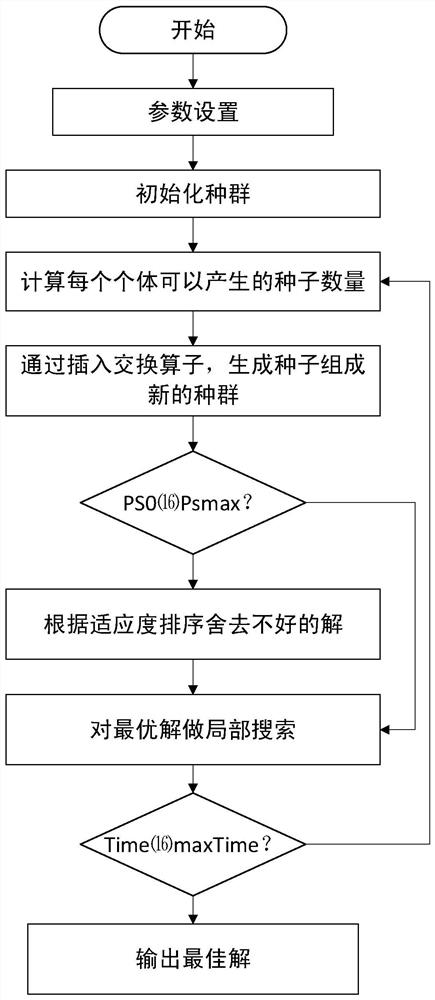

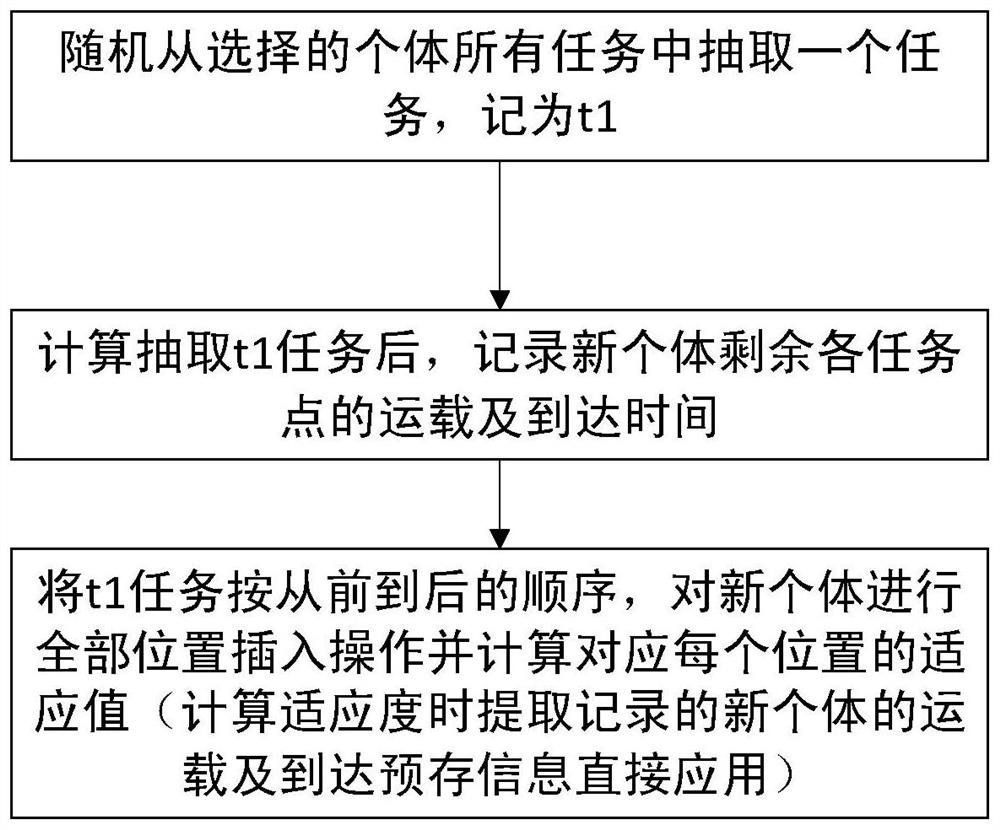

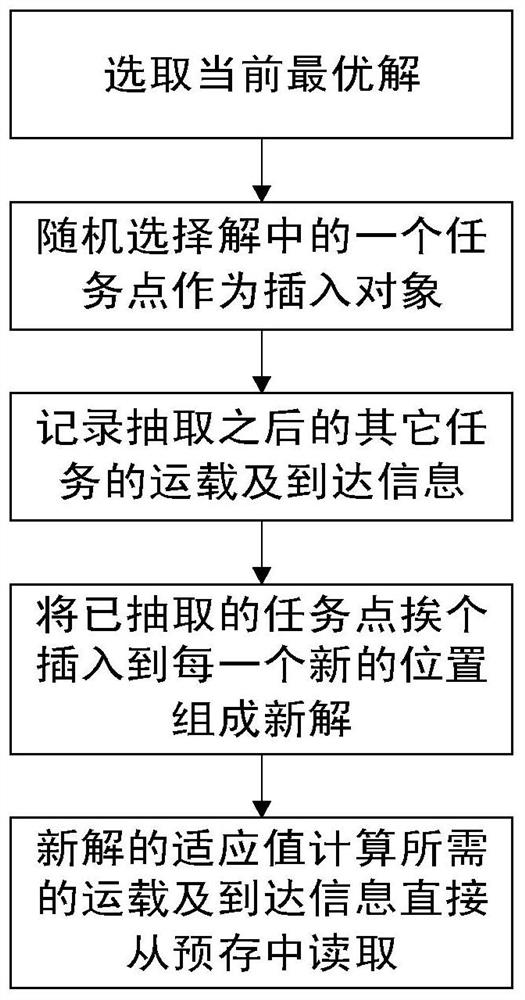

[0030] Such as Figure 1-3 As shown, the discrete optimization method based on matrix workshop AGV scheduling provided by the present invention mainly includes the following implementation process:

[0031] 1. Preset the relevant parameters of the discrete weed optimization algorithm.

[0032] Mainly include: initial population size, maximum population size, minimum seed number and maximum seed number. According to the existing AGV scheduling case of an actual factory, the existing algorithm is calibrated, and the preset value of the algorithm is calibrated by using 30 examples in the actual example to find out the parameter setting suitable for the problem. According to the results of the algorithm operation, the initial population can be set as PS 0 , set the maximum population size to PS max , set the minimum seed number to S 0 , set the maximum number of seeds to S max .

[0033] 2. Initialize the population. In the population-based optimization algorithm, the initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com