Preparation method and application of a flexible self-supporting silicon/carbon nanotube film composite electrode

A carbon nanotube film and composite electrode technology, which is applied in electrode manufacturing, electrode rolling/calendering, nanotechnology, etc., can solve the problems of loose film structure, poor bending resistance, and cumbersome steps, and achieve good flexibility and Improvement of bending resistance, specific capacity and cycle performance, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of modified silicon powder 1. Weigh 4.85g of commercial silicon powder, 0.15g of expanded graphite and pour it into a ball mill jar, and then add an appropriate amount of ethanol. Put the ball mill into the ball mill for 2~4h. After the ball milling is completed, the suspension liquid is poured into a beaker, transferred to an 80 °C oven to dry for 12 h, and the modified silicon powder is obtained after grinding into a powder.

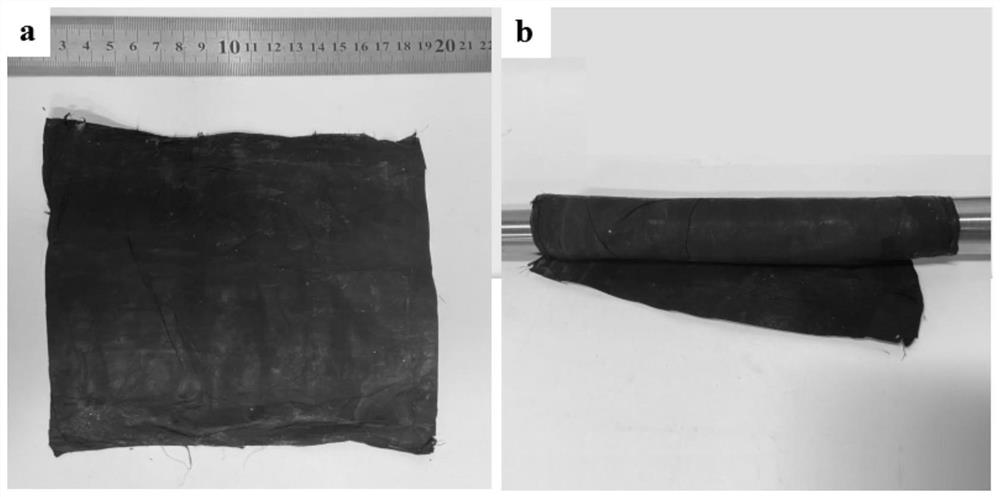

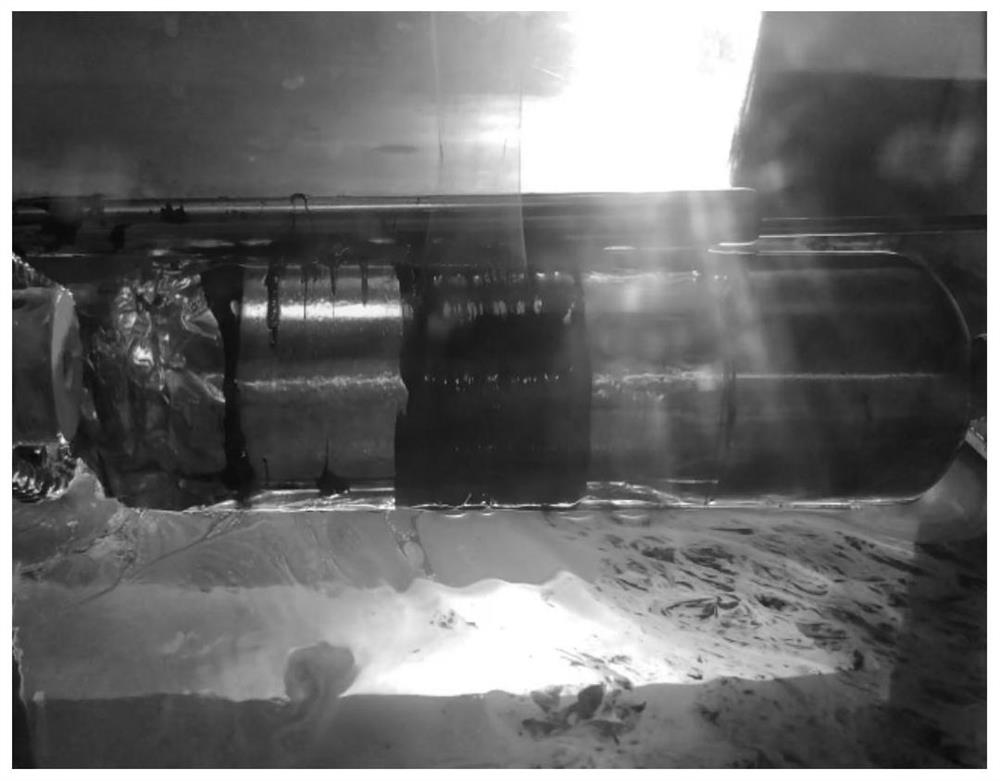

[0027] (2) Preparation of flexible silicon / carbon nanotube composite film. Weigh 0.987 g of ferrocene and 0.49 g of thiophene and pour 50 ml of ethanol into an ultrasound for 30 min. Draw all the mixed solution into the syringe and set aside. Vertical tubular furnace in argon atmosphere heating up to 1150 ~ 1190 °C, at a speed of 900sccm into hydrogen, 100sccm speed into argon, maintain more than 5min, under this condition, with a micro-syringe pump in the intake end of the ultrasonic good solution at a rate of 15ml / h injection int...

Embodiment 2

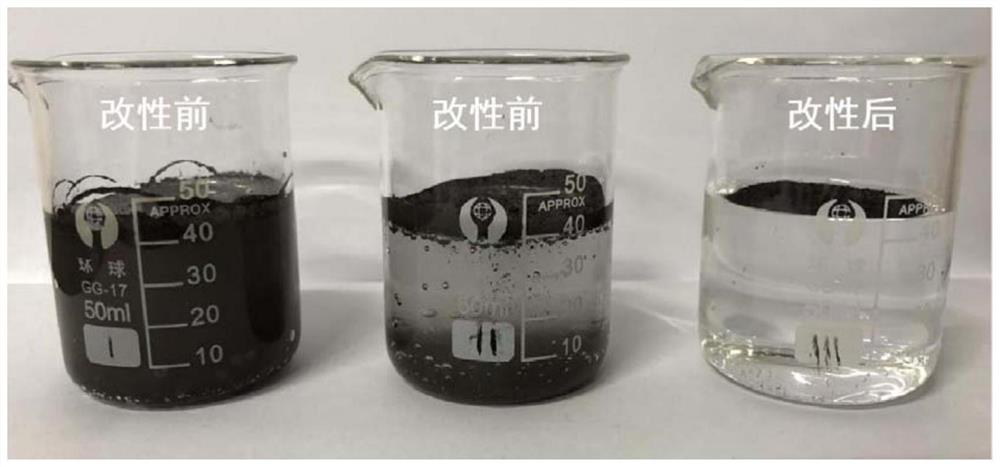

[0032] (1) Preparation of modified silicon powder 2. Add 80ml of ethanol in a beaker, heat to 40 °C and hold, turn on magnetic stirring, slowly add 0.25g CTAB (cetyltrimethylammonium bromide) powder, completely dissolved, add 5g of nano silicon powder, magnetic stirring for 2h, drying, grinding, to obtain a modified silicon powder that can float on the surface of the water without settling.

[0033] (2) Preparation of flexible silicon / carbon nanotube composite film. This step is the same as step (2) in Example 1.

[0034] (3) Preparation of flexible electrodes. This step is the same as step (3) in Example 1, after weighing comparison, the load amount of silicon is 45%.

[0035] (4) Battery encapsulation. This step is the same as step (4) in Example 1.

[0036] (5) Performance test. The test conditions are the same as in Example 1. The test results show that the discharge capacity for the first time can reach 2530mAh / g, the specific capacity of the second turn is reduced to 1076mAh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap