General-purpose aircraft engine disassembly and assembly vehicle

A technology for aircraft engines and disassembly racks, applied in aircraft parts, ground devices, transportation and packaging, etc., can solve problems such as poor versatility, and achieve the effect of saving manufacturing and improving the degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

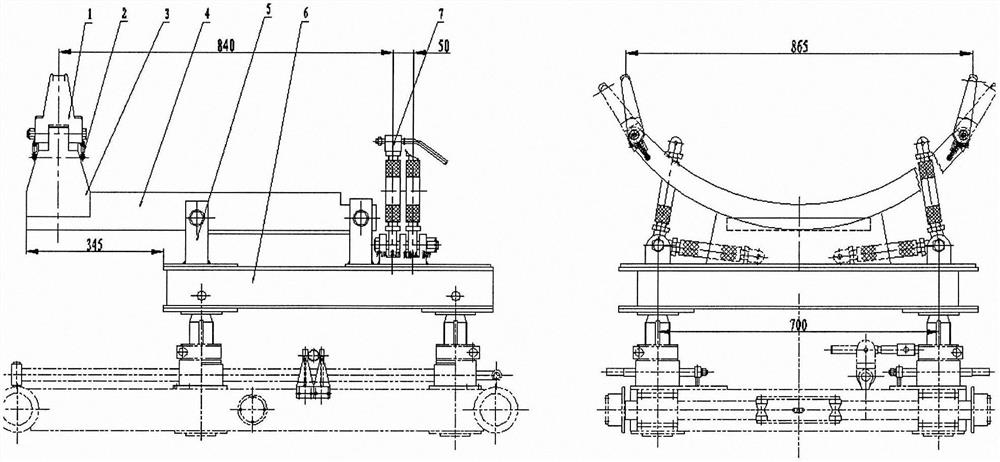

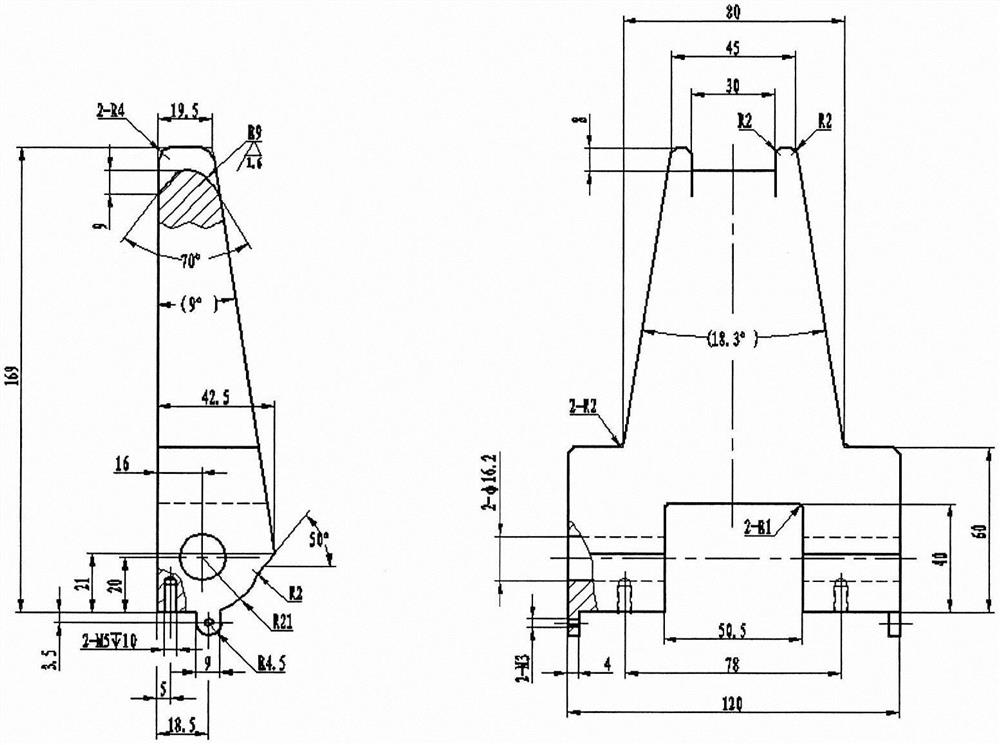

[0015] A generalized aircraft engine disassembly and assembly vehicle of the present invention is composed of two parts: the original engine disassembly and assembly vehicle and the newly designed mounting frame trolley. The mounting bracket trolley (see figure 2 ), consisting of two lugs 1, two floating support mechanisms 2, a supporting plate 3, an arc-shaped plate 4, a support plate 5, a transition base 6, and two tie rods 7, see Figure 3-Figure 8 . .

[0016] The support plate 5 of the mounting frame trolley and the transition base 6 are connected by welding, and the rest are connected by bolts. The connection between the original engine disassembly frame car and the installation frame trolley is connected together through the roller and the positioning guide rail mechanism.

[0017] When in use, the lugs are installed at both ends of the supporting plate to support the front support of the engine. The supporting plate and the arc-shaped plate are connected by 8 count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com