Reversion device of cooling equipment for wire rolling

A technology of cooling equipment and wire rod rolling, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., and can solve the problems of affecting the surface quality of products, infringing on the life accuracy, and producing yin and yang surfaces of wire rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

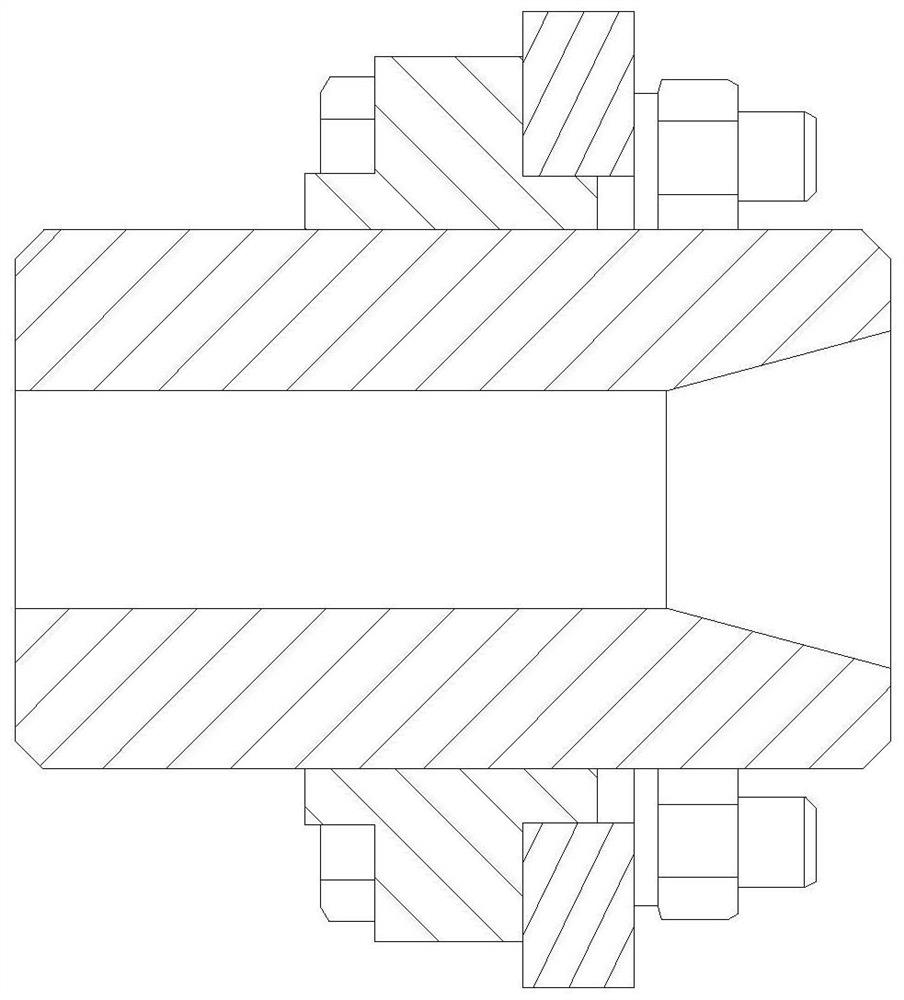

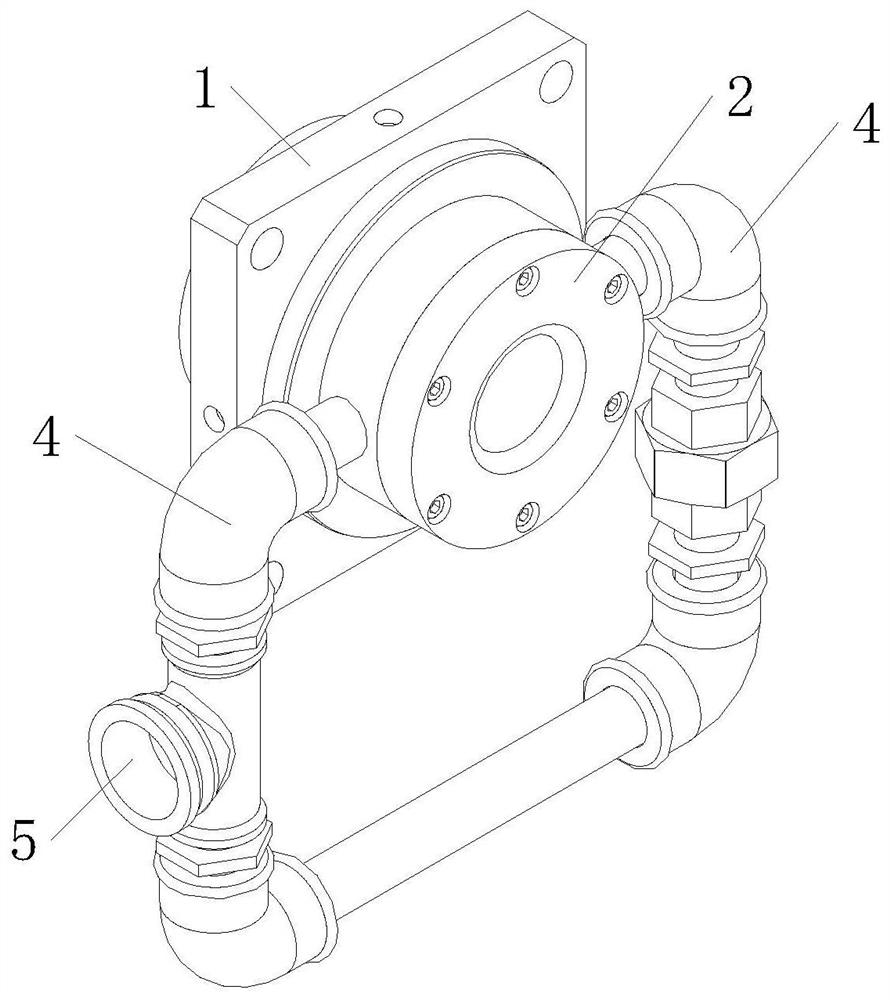

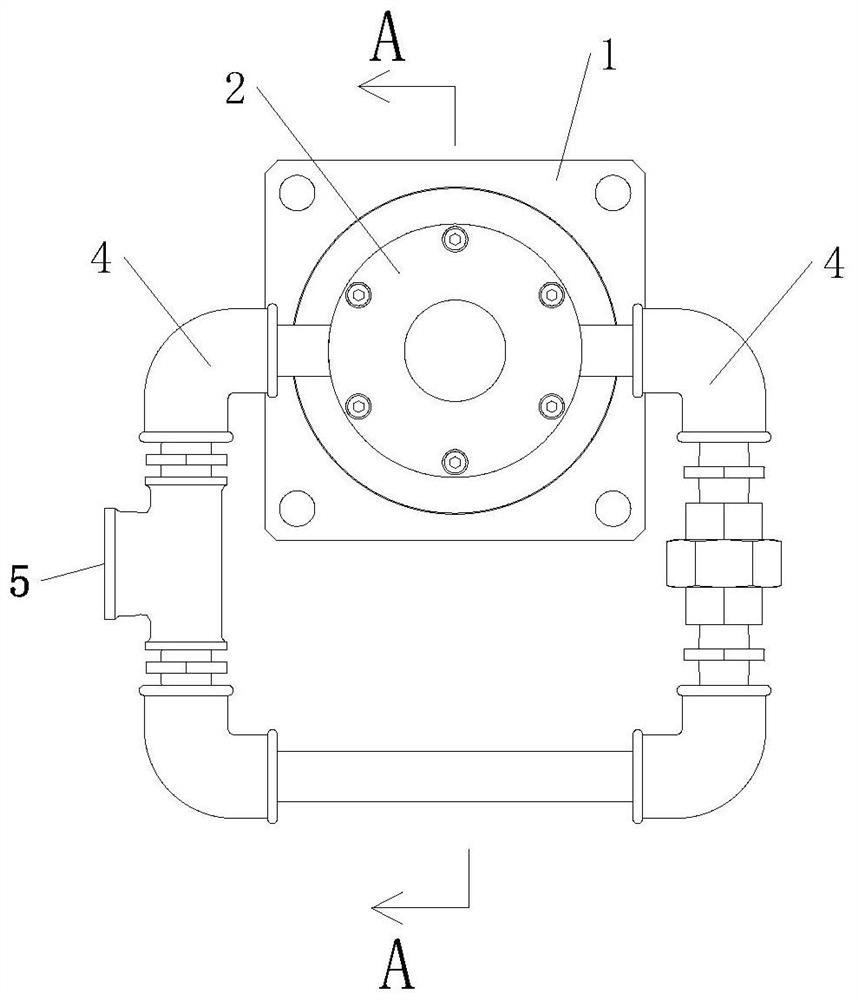

[0025] Such as Figure 2-4 As shown, a counterattack device for cooling equipment for wire rolling includes a mounting plate 1 and a guide pipe 2. There are through holes on the mounting plate 1, and the mounting plate 1 is fixed and sealed at the outlet of the cooling equipment by screws. The device also includes a counterattack sleeve 3, which is sealed and embedded in the central hole of the installation plate 1, one end of the inner hole of the counterattack sleeve 3 is fixed in diameter, and the other end of the counterattack sleeve 3 is a diameter that gradually shrinks. Reduced diameter, diameter reduction is the smallest diameter at the inner hole port of the counterattack sleeve 3, the port diameter of the reduced diameter section 31 of the counterattack sleeve 3 is greater than the inner diameter of the guide tube 2; the outer diameter of the guide tube 2 is greater than The inner diameter of the sizing section 32 of the counterattack sleeve 3, one end of the guide p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap