Vacuum heat insulator and refrigerator

A technology for vacuum insulation and refrigerator, which is applied to household refrigerators, lighting and heating equipment, cooling fluid circulation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the following description, orientations or positional relationships indicated by "front", "rear", "upper", "lower", "left", "right", etc. are orientations based on the refrigerator 200 itself as a reference.

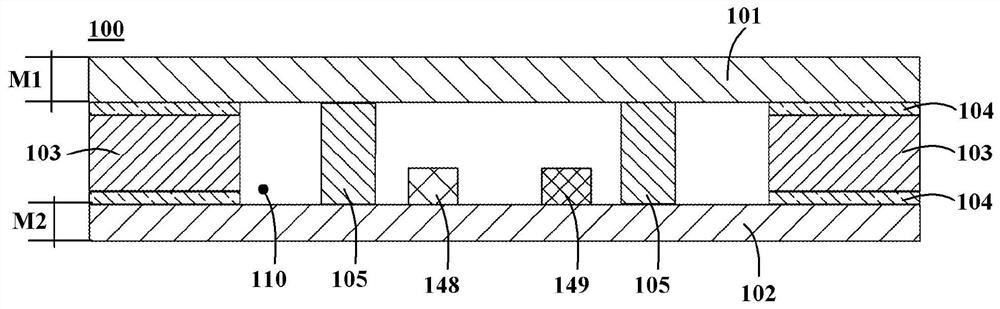

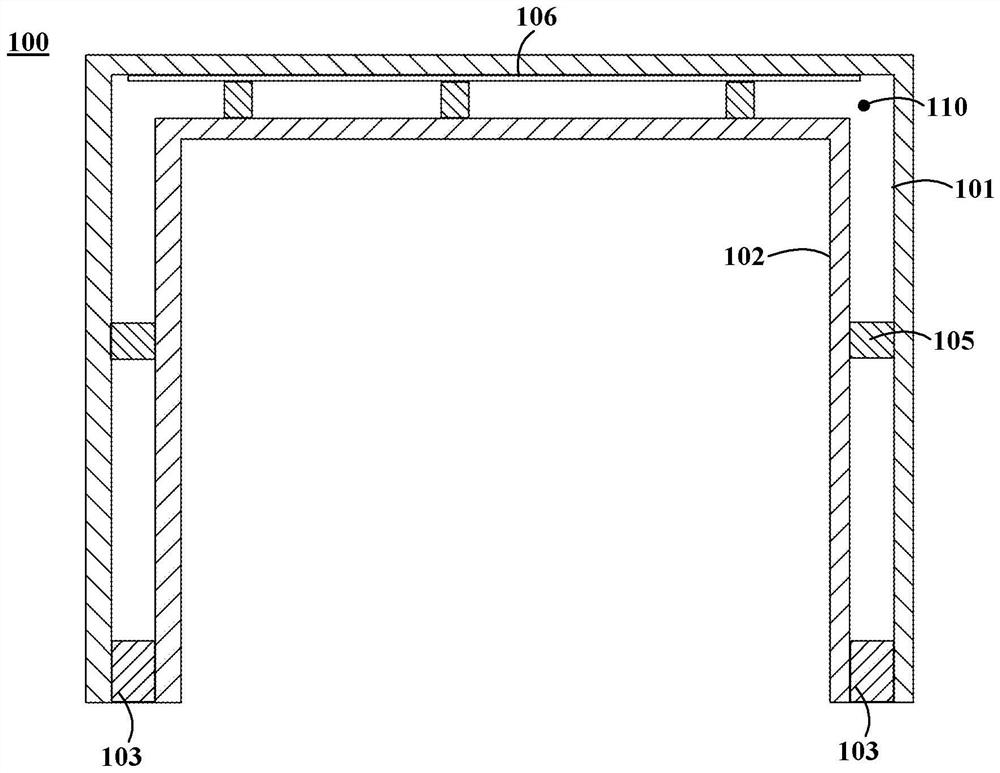

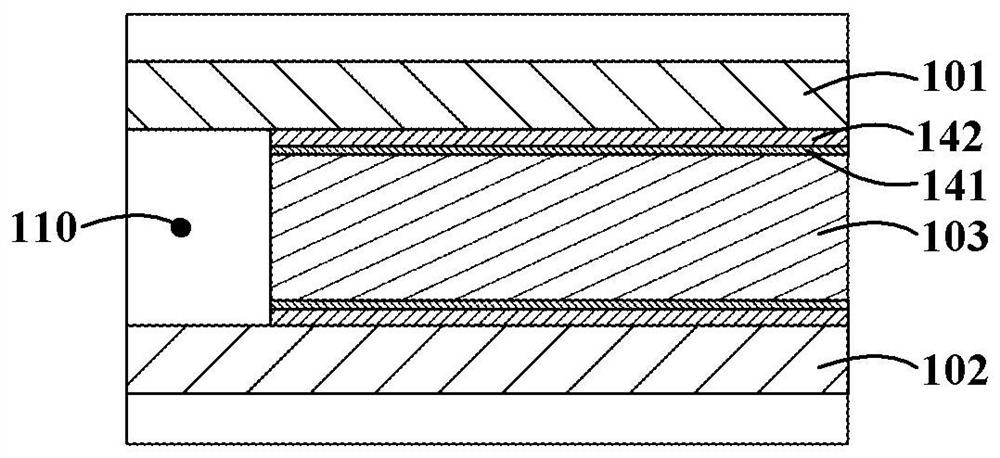

[0053] figure 1 is a schematic cross-sectional view of a vacuum insulator 100 according to an embodiment of the present invention. figure 2 is a schematic cross-sectional view of a vacuum insulator 100 according to another embodiment of the present invention. Such as figure 1As shown, the vacuum insulation body 100 of the embodiment of the present invention includes: a first plate 101 , a second plate 102 and a sealing member 103 . The first board 101 has a first thickness M1; the second board 102 is arranged at a distance from the first board 101, and the second board 102 has a second thickness M2, and the first thickness M1 is greater than the second thickness M2. The sealing member 103 is arranged between the first plate 101 and the second plate 102, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com