Electronic detonator with anti-interference structural design

An electronic detonator and structural design technology, applied in offensive equipment, weapon accessories, fuzes, etc., can solve the problems of complex sealing process, poor discharge effect and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

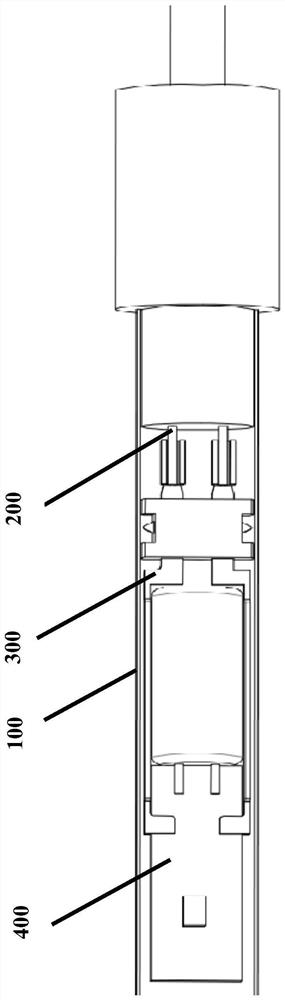

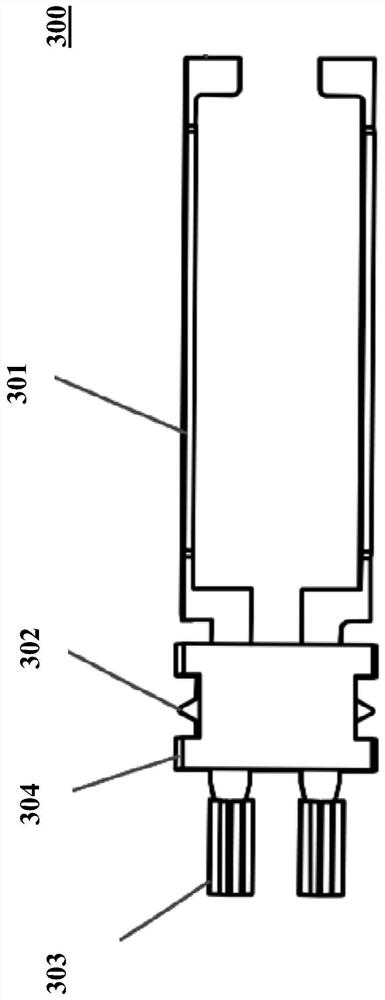

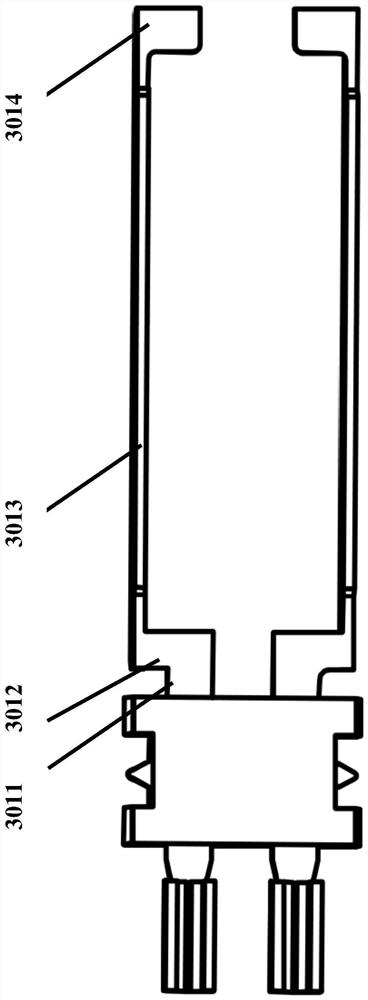

[0012] In order to release static electricity, prevent electrostatic interference, improve discharge effect, reduce cost, and be easy to process, the embodiment of the present invention provides an electronic detonator with an anti-interference structure design, such as Figure 1-Figure 2 As shown, the electronic detonator of this anti-jamming structure design comprises a shell 100, in which a detonator foot wire 200 connected in sequence, a capacitor support 300 and a PCB circuit board 400 are arranged, and the capacitor support 300 includes: placed in parallel The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com