Tunnel section deformation monitoring method

A technology of deformation monitoring and cross-section, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of dust accumulation on reflective targets, reducing the accuracy of monitoring results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

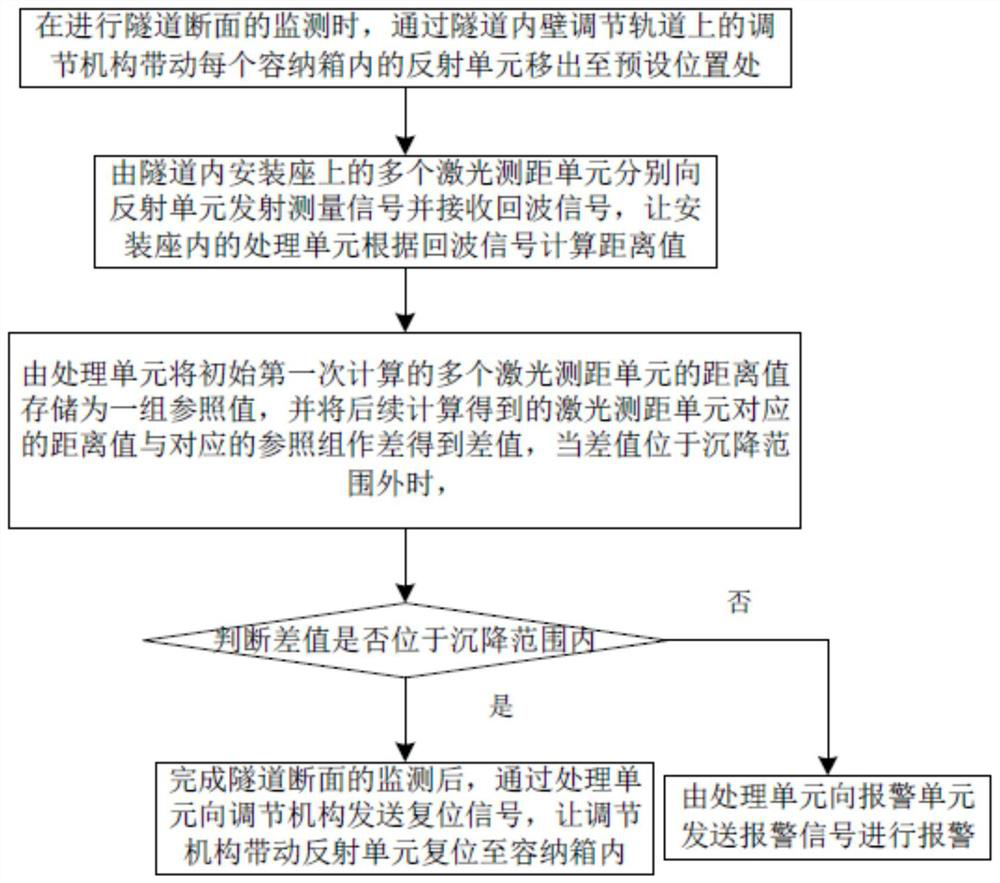

Method used

Image

Examples

Embodiment 1

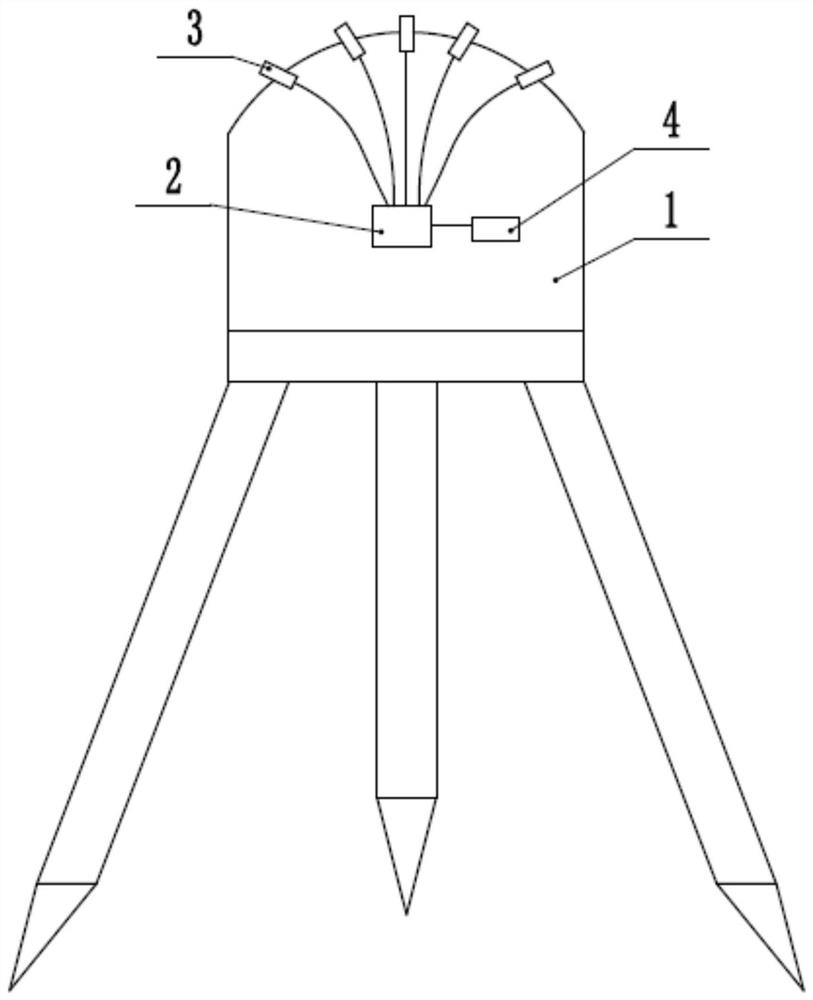

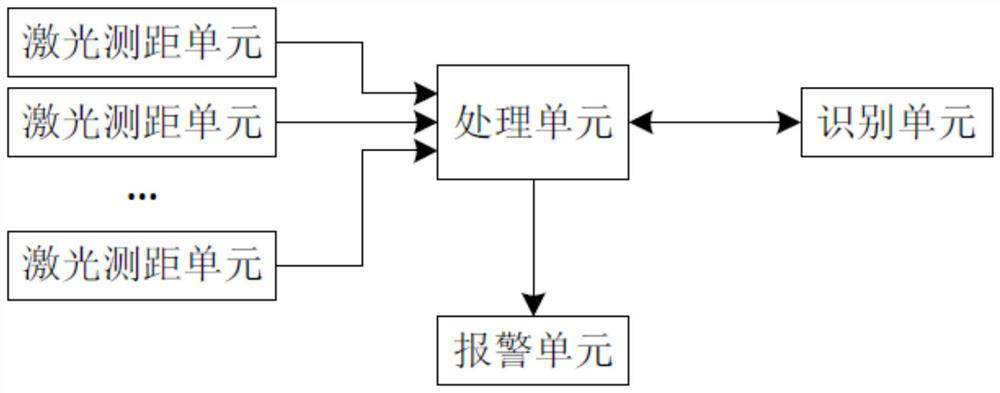

[0038] In order to realize the method, the first embodiment also discloses a tunnel section deformation monitoring device, such as figure 2 , image 3 and Figure 4 As shown, the mounting base 1 is included. The mounting base 1 is placed in the tunnel through a tripod for use. The mounting base 1 is equipped with an alarm unit, a processing unit 2, an identification unit 4 and a plurality of laser ranging units 3. The laser ranging unit 3 are evenly distributed on the same arc of the mounting base 1, and the laser distance measuring unit 3 can be an existing infrared laser transmitter.

[0039] Such as Figure 5As shown, the laser ranging unit 3 is equipped with a plurality of reflection units 17 located on the inner wall of the tunnel, and also includes an adjustment track 5 located on the inner wall of the tunnel. The radial section of the adjustment track 5 is concave, and the adjustment track 5 can be screwed It is fixed to the inner wall of the tunnel, and the adjustm...

Embodiment 2

[0049] The difference from Embodiment 1 is that in step S3, the processing unit 2 judges whether the tunnel type is under construction. If the tunnel type is under construction, when the difference is outside the settlement range, the processing unit 2 will The size of the alarm unit sends alarm signals of different levels of information, and the detector in the alarm unit detects the human body signal in the tunnel. When the human body signal is detected, the controller of the alarm unit judges the level information of the alarm signal and controls the alarm. The power device located at the human body signal in the unit drives the alarm 11 to perform a level alarm of the illumination mode; specifically, the processing unit 2 judges whether the tunnel type is a built-up type, and if the tunnel type is a built-up type, multiple alarms 11 are set and The alarms 11 are installed along the inside and outside of the tunnel, and the controller controls all the alarms 11 to perform le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com