A detection tool and detection method for pipelines with insulation layer

A technology for pipeline inspection and thermal insulation layer, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of the imaging board and the ray source being difficult to maintain a vertical state, and the detection accuracy is low, so as to facilitate the rotation of the installation ring and improve the detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following is attached Figure 1-8 The application is described in further detail.

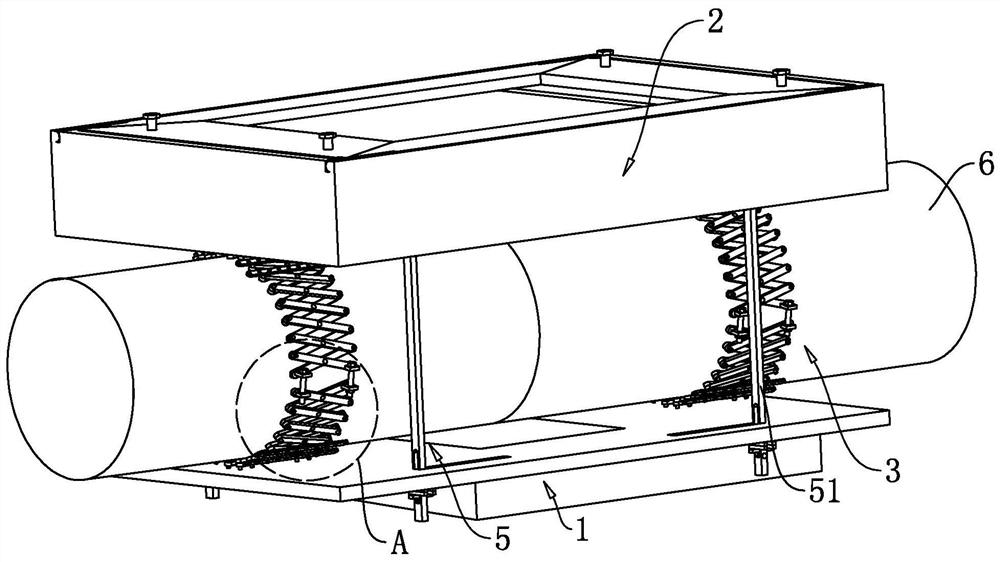

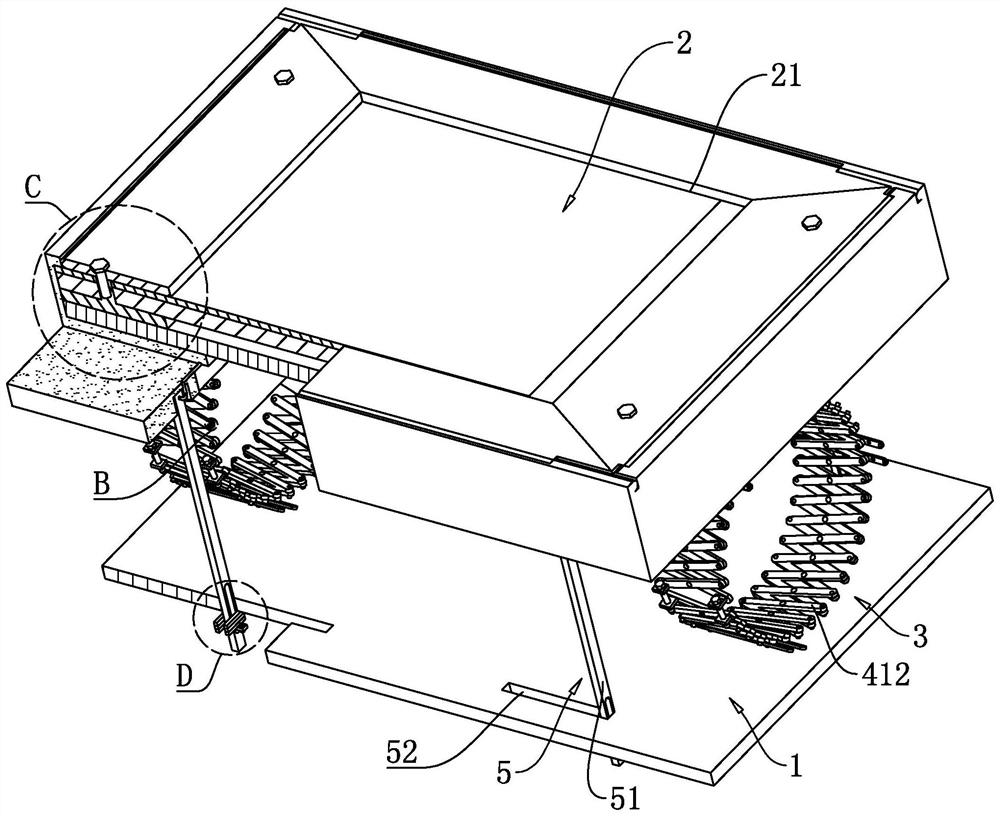

[0062] The embodiment of the present application discloses a digital ray detection tool for a pipeline with an insulation layer. refer to figure 1 , a kind of inspection tooling and detection method for pipelines with insulation layers, comprising an installation ring 3 and a ray machine 1 and an imaging plate 2 arranged at both ends of the diameter direction of the installation ring 3, when performing digital ray detection on a pipeline with an insulation layer 6, the The mounting ring 3 is fixed on the X-ray machine 1 and the imaging board 2, so that a vertical state is formed between the radiation source on the X-ray machine 1 and the imaging board 2, so as to improve detection accuracy.

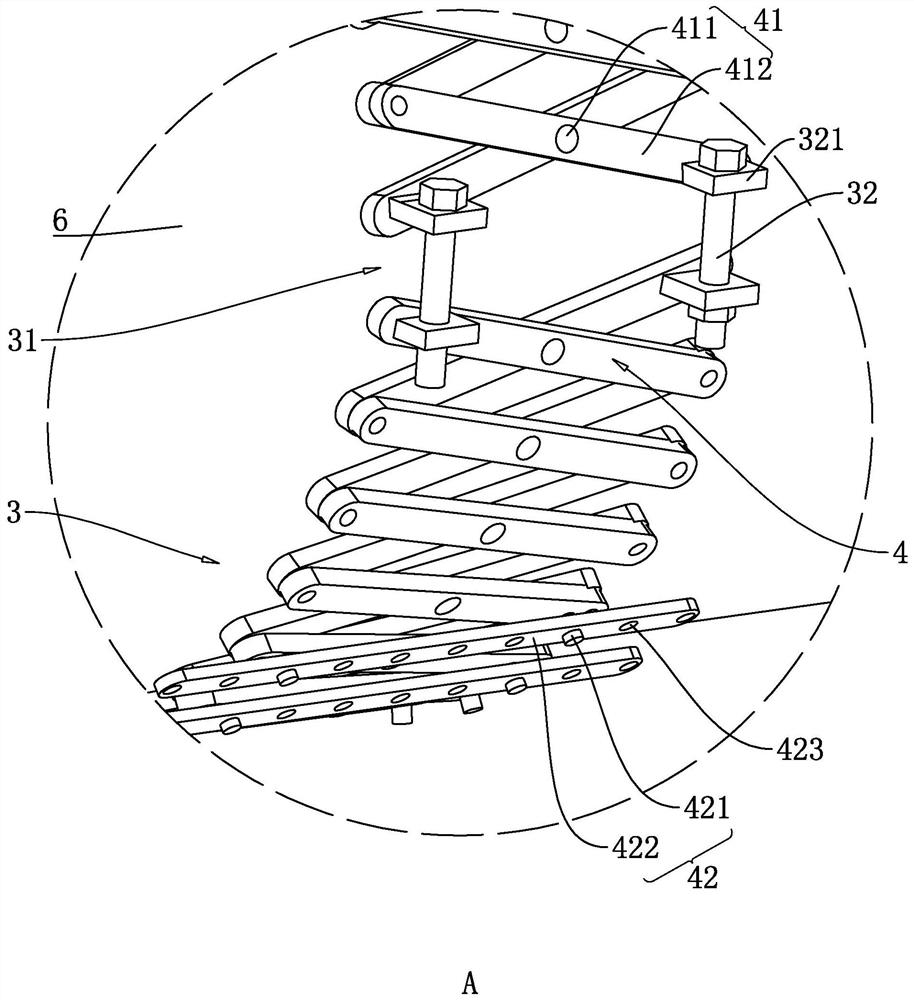

[0063] refer to figure 2 , the mounting ring 3 is provided with an opening 31, and when the weld seam on the pipeline 6 with the insulation layer is detected, the installation ring 3 is slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com