Fuel pressure waveform acquiring equipment for fuel injection system

A technology of fuel injection system and fuel pressure, which is applied to fuel injection device, fuel injection control, charging system, etc., can solve the problem that the pressure waveform W cannot be accurately obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

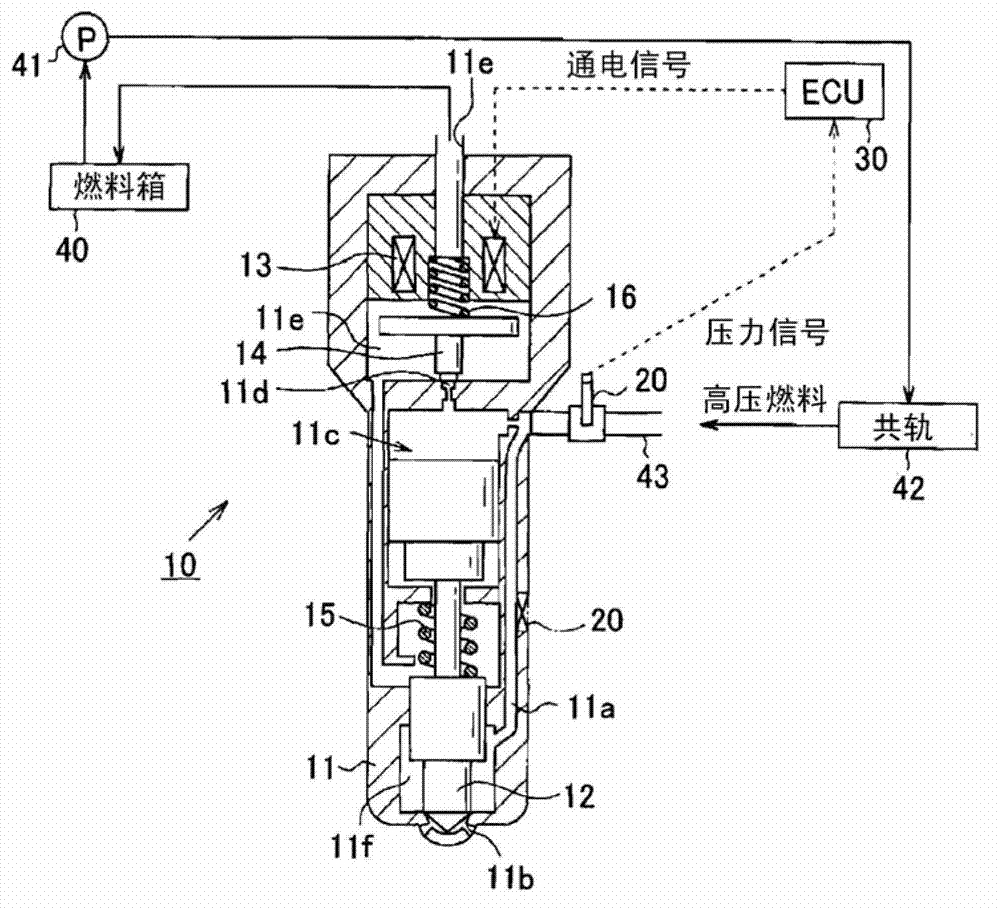

[0045] figure 1 The structure of a fuel injection system for a vehicle-mounted internal combustion engine is schematically shown, and the system includes a fuel pressure waveform acquisition device according to an embodiment of the present invention. In this embodiment, the internal combustion engine is a diesel engine having cylinders #1 to #4 for performing compression auto-ignition combustion. The fuel injection system operates to inject high-pressure fuel into cylinders #1 to #4.

[0046] exist figure 1 In, reference numeral 10 denotes a fuel injection valve mounted on each cylinder #1 to #4, 20 denotes a fuel pressure sensor mounted on the fuel injection valve 10, and 30 denotes an ECU (Electronic Control Unit) mounted on the vehicle ) 30. The fuel pressure waveform acquisition means is implemented by the ECU 30 . The fuel injection system operates such that fuel stored in a fuel tank 40 is fed to a common rail 42 as an accumulator through a high pressure pump 41 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com