Plastic dropper mold

A dropper and mold technology, used in household appliances, tubular items, other household appliances, etc., can solve the problems of reduced service life, high wear and tear, increased production and maintenance costs, etc., to reduce service life, improve service life, and increase The effect of large production maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

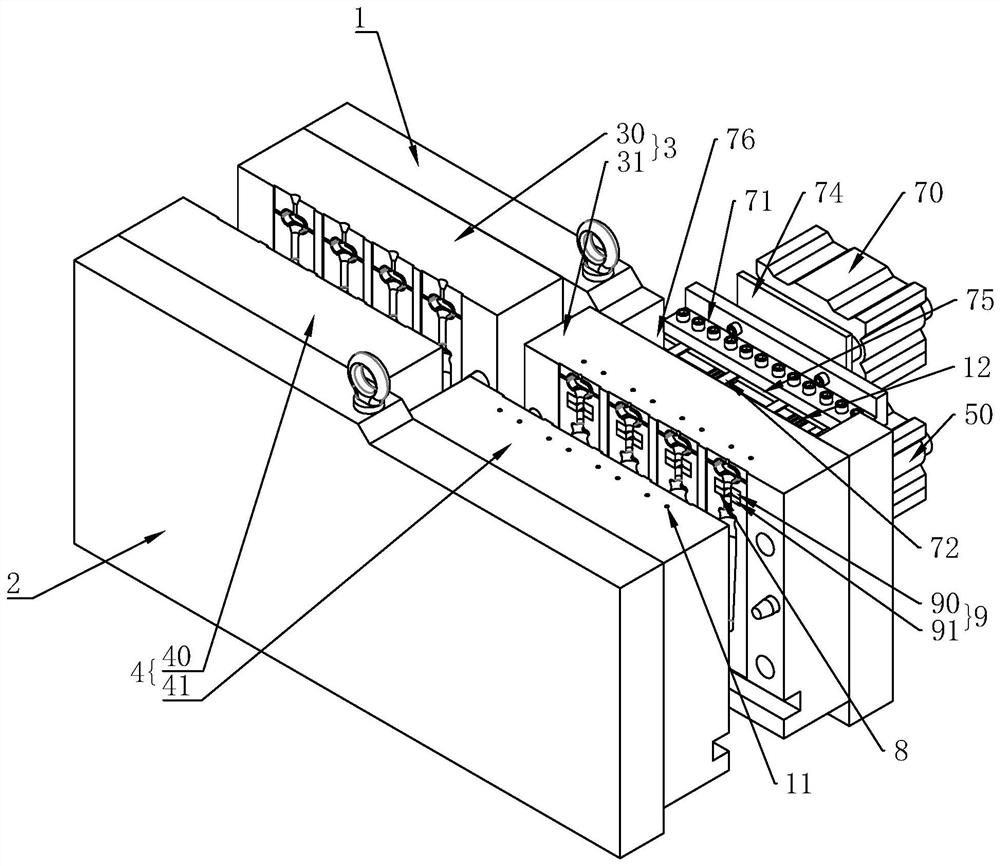

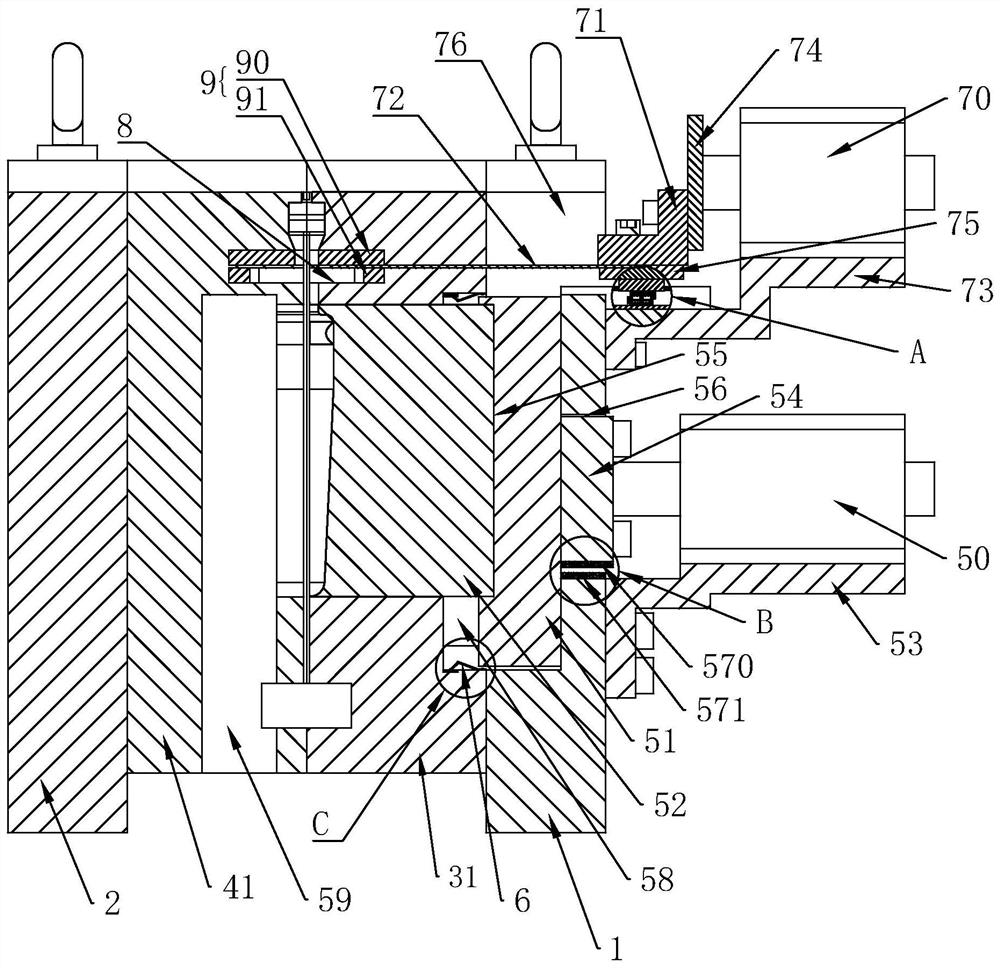

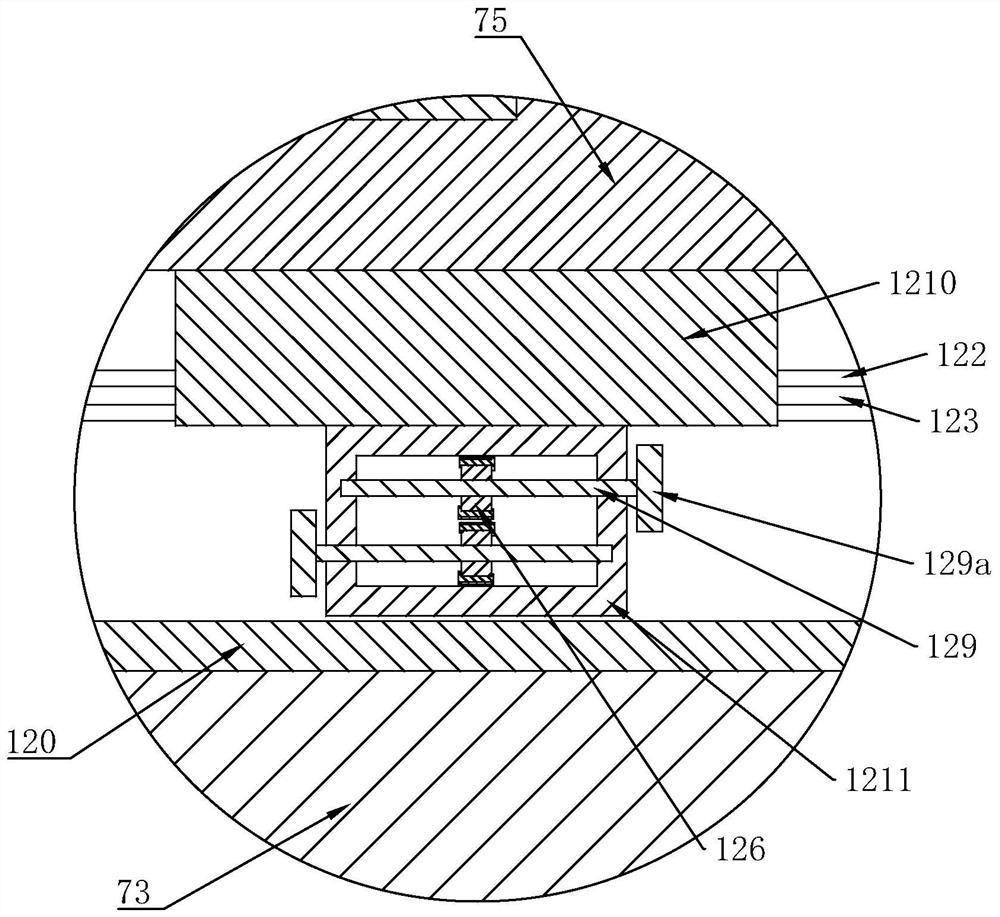

[0028] Combine below Figure 1 to Figure 8 The present invention is further described with specific embodiment:

[0029] A plastic dropper mold, comprising a front mold frame 1, a rear mold frame 2, a front template 3 and a rear template 4, the front template 3 includes a front molding template 30 and a front finished template 31, and the rear template 4 includes a rear molding Template 40 and rear finished template 41, described front molding template 30 corresponds to rear molding template 40, and front finished template 31 corresponds to rear finished template 41. On the front mold base 1 and at the front finished template 31 places The push knife structure 7 and the push tube structure 5, the above-mentioned front forming template 30, rear forming template 40, front finished template 31 and rear finished template 41, and the front formwork 1 and the rear formwork 2 are preferably installed and fixed by bolts.

[0030] As can be seen from the above structure, by installing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap