Self-adaptive shockproof designed packaging transportation device

A technology for transportation devices and packaging, which is applied in the field of design and packaging transportation devices, can solve the problems of limited shock absorption effect, attenuation vibration, difficulty, etc., to prevent damage to goods, reduce vibration amplitude, and prevent excessive vibration amplitude Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

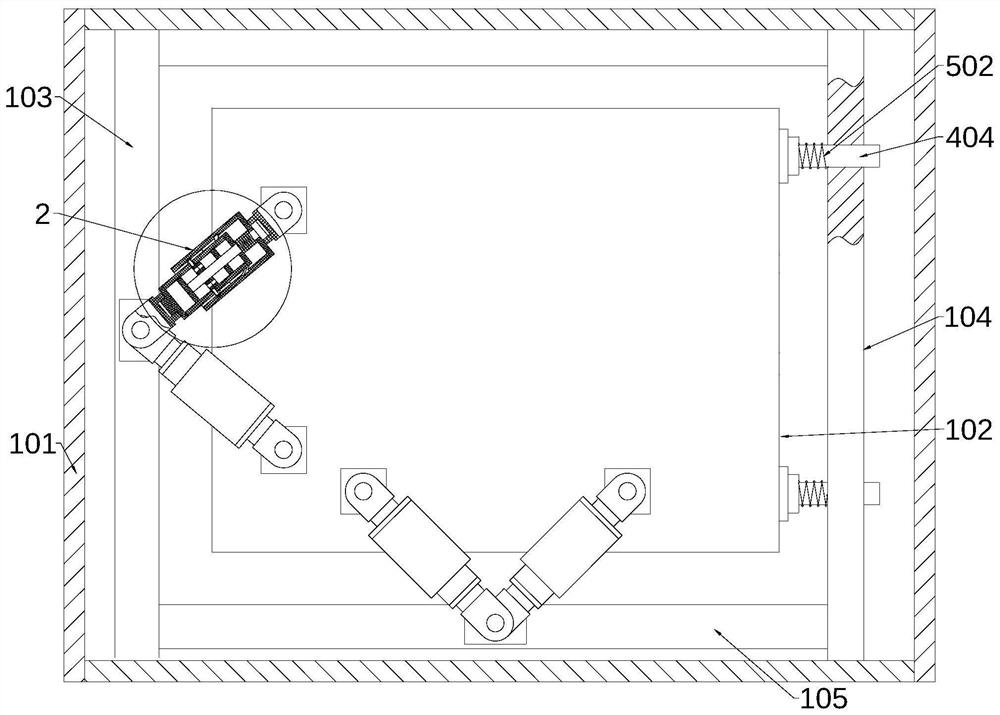

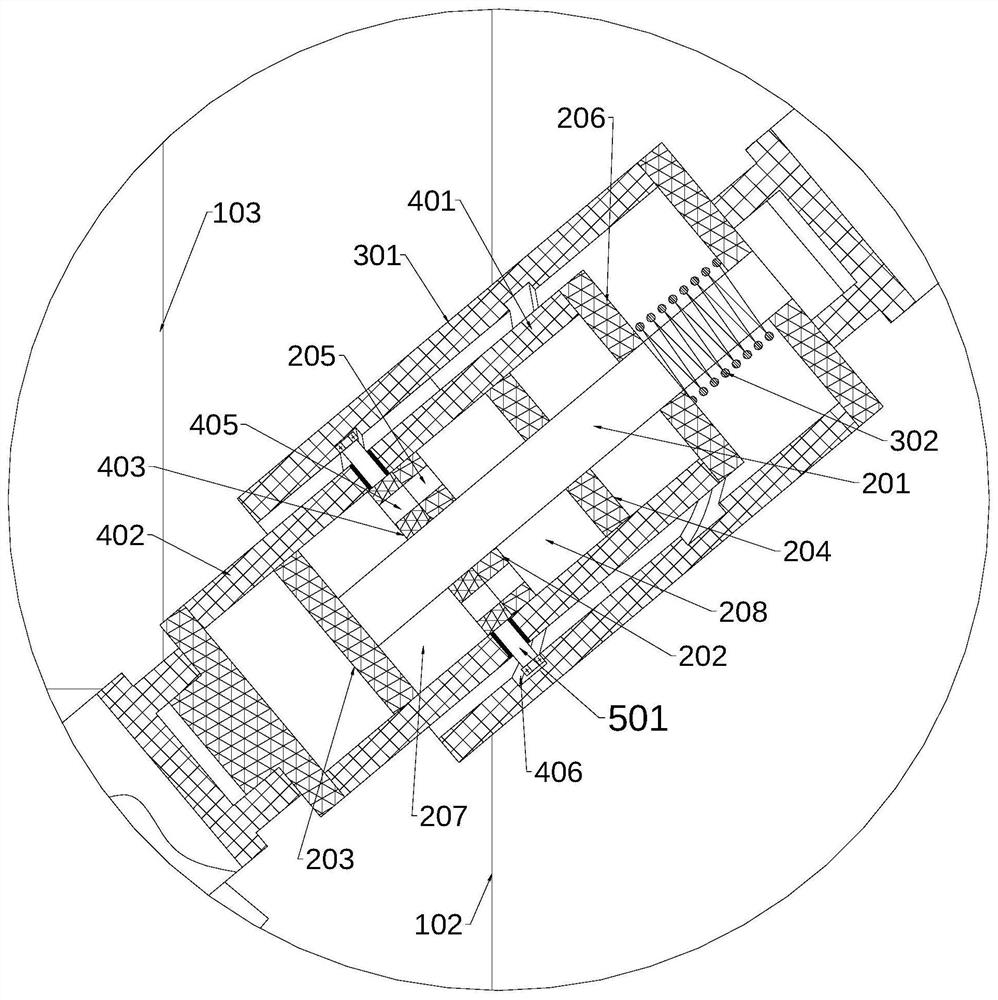

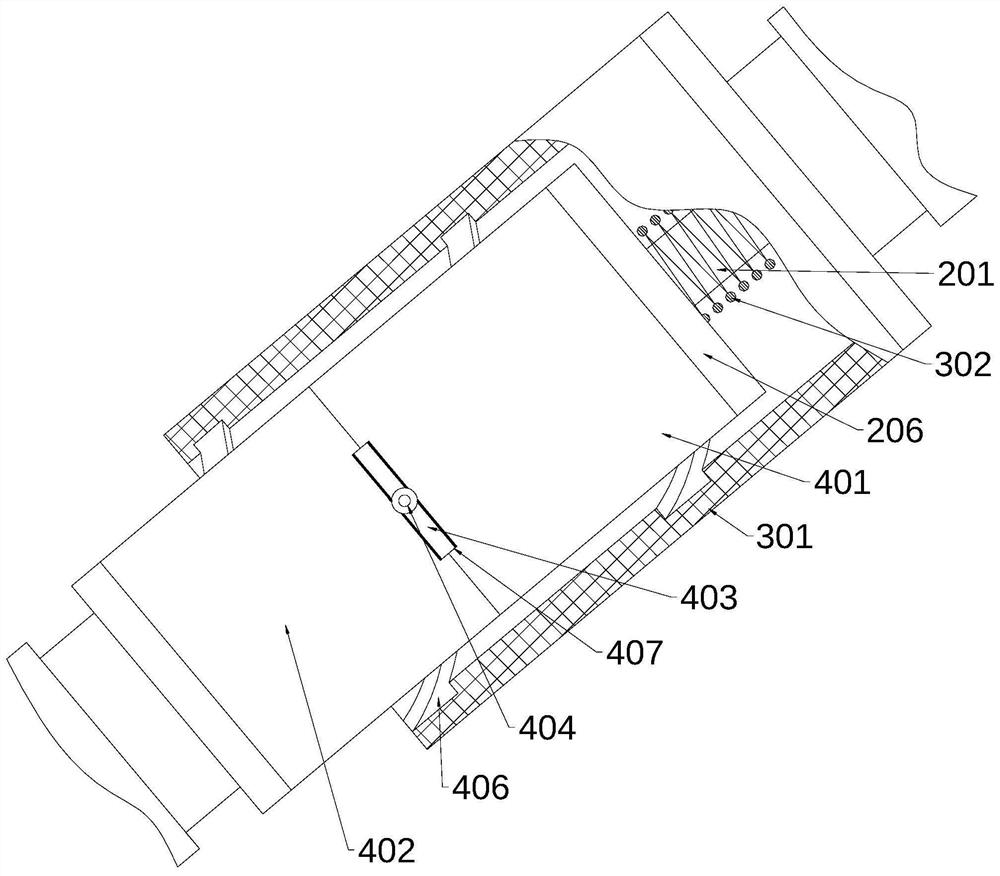

[0024] Such as Figure 1-3 As shown, the present invention provides a self-adaptive anti-shock designed packaging transportation device, including: an outer box 101, an inner box 102, a truss and multiple sets of energy consumers 2, and an outer box 101 installed on a transport vehicle Above; the truss is fixed to the inner wall of the outer box; the inner box 102 is arranged in the outer box 101 for storing goods; multiple sets of energy consumers 2 and each group of energy consumers 2 includes two energy consumers 2 , one end of the two energy dissipators 2 is jointly hinged on the truss, and the other ends of the two energy dissipators 2 are respectively hinged at different positions on the side wall of the inner box 102, the energy dissipator 2 includes a sleeve 301, a piston rod 201, the first piston head 203, the second piston head 204, the upper cylinder liner 401, the lower cylinder liner 402 and the fixed partition 202, the sleeve 301 is hinged to the side wall of the...

Embodiment 2

[0030] On the basis of Embodiment 1, in order to reduce high-frequency vibration, the first piston head 203 and the second piston head 204 are quickly reset after moving relative to the cylinder liner, and the first piston head 203 and the second piston head 204 are lowered against the cylinder liner. the impact caused.

[0031] Such as figure 2 and 3 As shown, wherein, the upper cylinder sleeve 401 is also fixedly connected with the cylinder head 206, the cylinder head 206 is provided with a central through hole, the central through hole is slidably connected with the piston rod 201, and the inner wall of the cylinder sleeve 301 is in contact with the piston rod 201. A first spring 302 is also provided between the cylinder heads 206 .

[0032] By setting the first spring 302 and selecting a spring with a suitable elastic coefficient, high-frequency vibration can be effectively reduced, and under the action of the elastic force of the first spring 302, the first piston head...

Embodiment 3

[0034] On the basis of Embodiment 1, in order to prevent the first connecting post 404 from being stuck due to excessive frictional force between the first connecting post 404 and the helical groove 406 .

[0035] Such as figure 2 and 3 As shown, a bearing is further provided between the first connecting column 404 and the spiral groove 406 , the first connecting column 404 is connected to the bearing, and the bearing is slidably connected to the spiral groove 406 .

[0036] By arranging the bearing, the frictional force between the first connecting column 404 and the spiral groove 406 can be effectively reduced, thereby effectively preventing the first connecting column 404 from being stuck.

[0037] As a preferred option, such as figure 2 As shown, wherein, the side wall of the opening groove 407 is also provided with a rubber pad, and the first connecting column 404 is in sealing and sliding connection with the rubber pad. By arranging the rubber pad, not only the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com