House building steel structure fabricated wallboard

A steel structure and assembly technology, applied in the direction of building construction, construction, covering/lining, etc., can solve problems such as wall panel damage, achieve the effect of easy disassembly and assembly, and improve connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

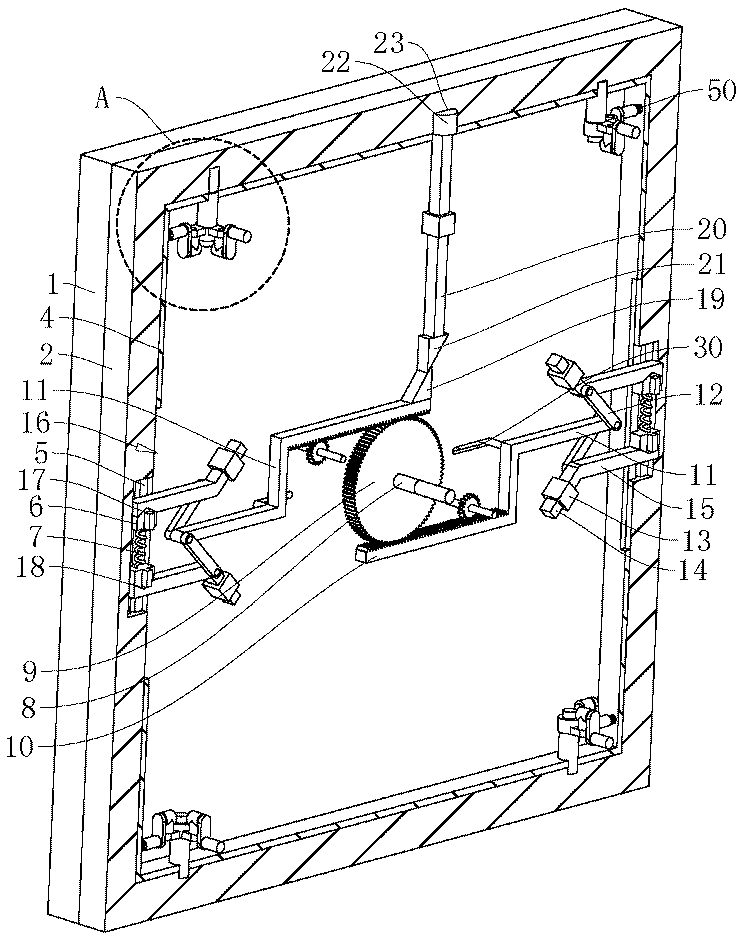

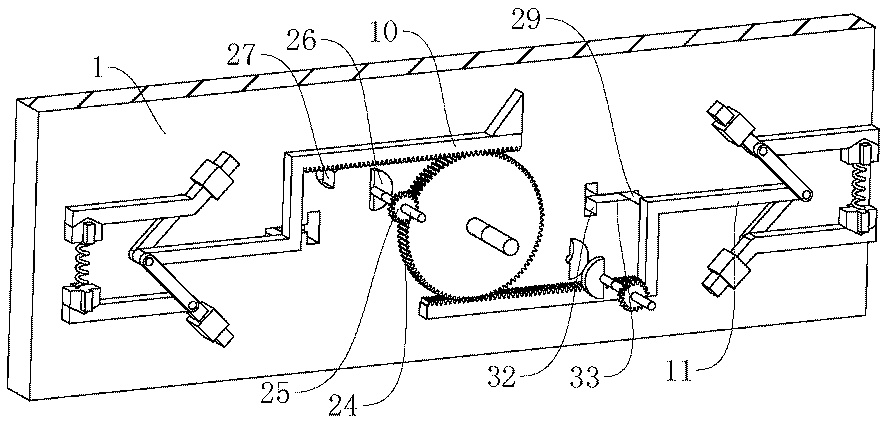

[0039] The following is attached Figure 1-7 The application is described in further detail.

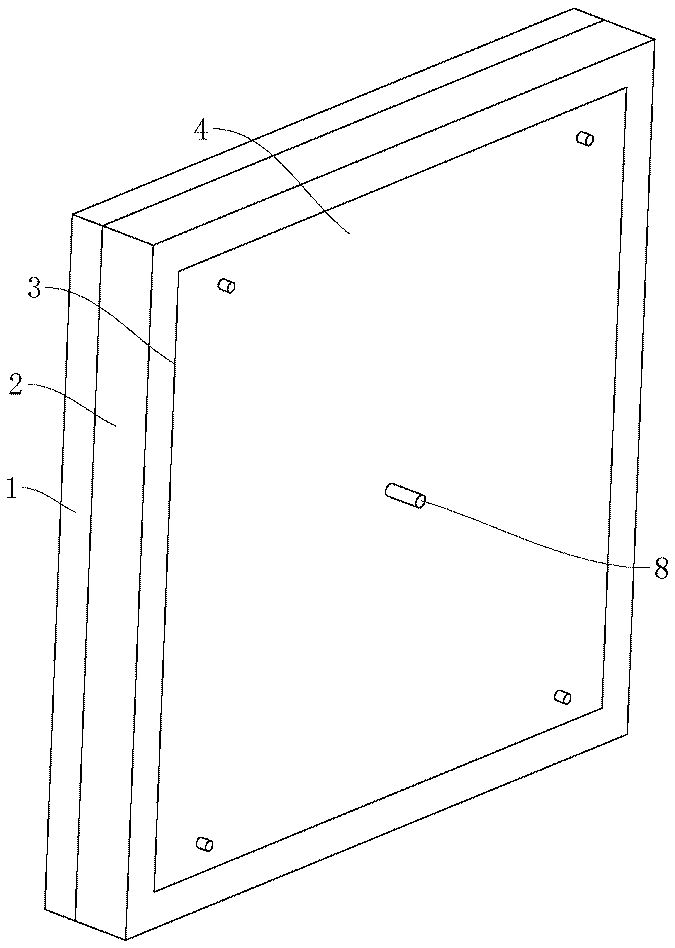

[0040] The embodiment of the application discloses a prefabricated wall panel of a house building steel structure. refer to figure 1 The prefabricated wall panel of the house building steel structure includes an installation frame 2, an installation port 3 and a wall panel 4, the installation frame 2 is arranged in a square shape, the installation frame 2 is fixed on the outside of the wall 1, and the installation port 3 is opened in the installation frame 2. The installation opening 3 runs through the opposite sides of the installation frame 2 , the wall panel 4 is installed in the installation opening 3 , and the four end surfaces of the wall panel 4 are attached to the four side walls of the installation opening 3 respectively.

[0041] refer to figure 2 , the middle position of the two left and right side walls of the installation port 3 is provided with a square installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com