Flexible piezoresistive sensor with multilayer structure and preparation method thereof

A technology of piezoresistive sensor and multi-layer structure, which is applied in the direction of fluid pressure measurement, instrument, and measuring device by changing the ohmic resistance, which can solve the problem of narrow detection range of flexible piezoresistive sensors and achieve the effect of expanding the sensing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

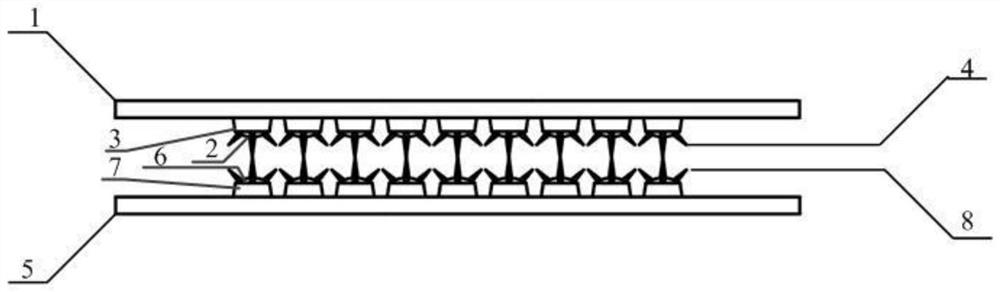

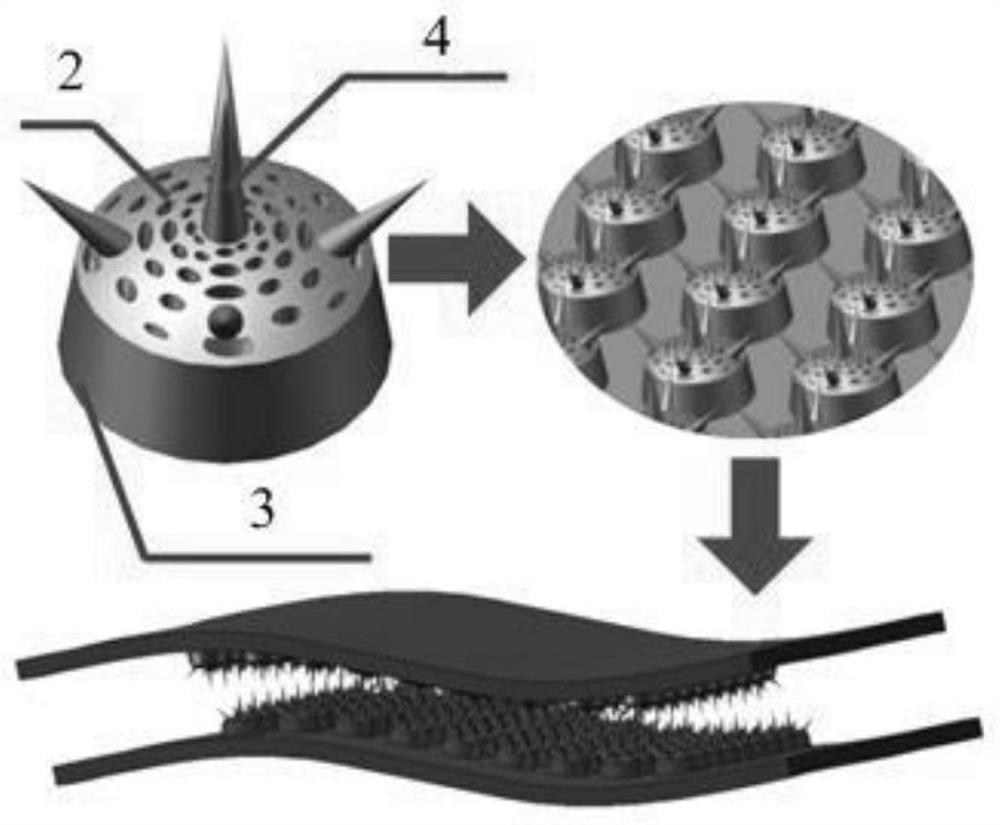

[0049] like figure 1As shown, a flexible piezoresistive sensor with a multilayer structure provided in this embodiment includes two identical flexible piezoresistive multilayer structural parts, which are respectively the first flexible piezoresistive multilayer structural part and the second flexible piezoresistive multilayer structural part. A multilayer structural part; the first flexible piezoresistive multilayer structural part includes a first flexible piezoresistive planar base layer 1, a first antenna structure 4 and a first porous dome structure; the first flexible piezoresistive planar base The upper surface of the bottom layer 1 is connected to the first electrode, and the lower surface of the first flexible piezoresistive planar base layer 1 is sequentially connected to the first porous dome structure and the first antenna structure 4; The resistance multilayer structure part comprises a second flexible piezoresistive planar base layer 5, a second antenna structure...

Embodiment 2

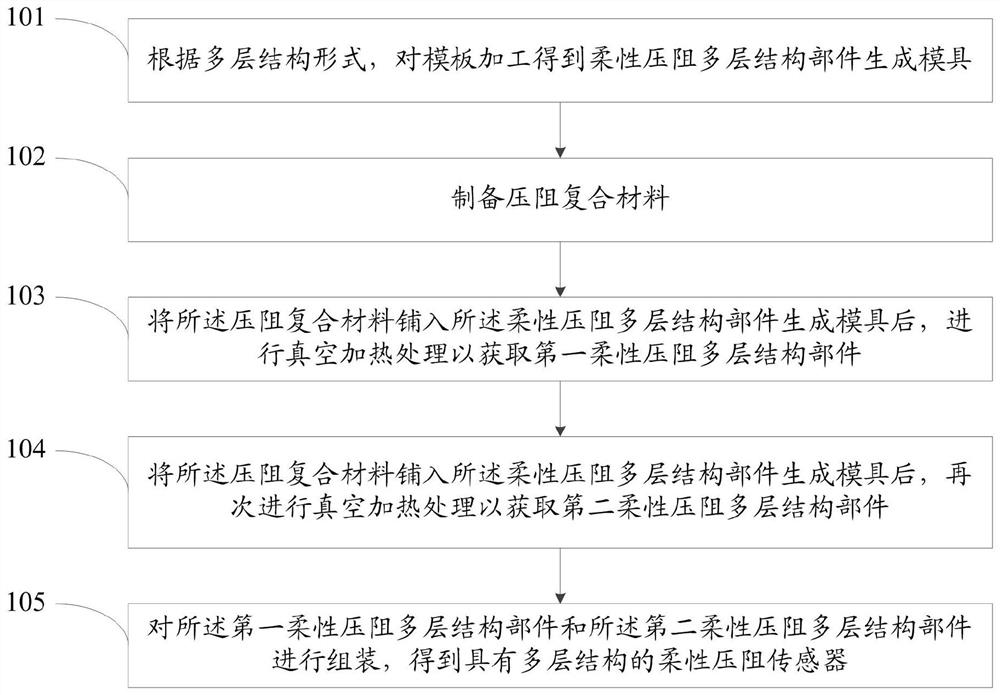

[0057] Such as image 3 As shown, a method for preparing a flexible piezoresistive sensor with a multilayer structure provided in this embodiment includes:

[0058] Step 101: According to the form of the multilayer structure, process the template to obtain a flexible piezoresistive multilayer structure component generation mold. In this embodiment, laser processing is performed on the template to obtain a flexible piezoresistive multilayer structure component generation mold.

[0059] According to the multi-layer structure, the template is processed to obtain a flexible piezoresistive multi-layer structure component generation mold, which specifically includes:

[0060] Performing a first perforation process on the template to obtain a perforated dome generating mold;

[0061] In this embodiment, performing the first punching process on the template to obtain the porous dome generation mold specifically includes: using drawing software to draw the punching aperture, the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com