Non-contact type power-off sensor

A non-contact, sensor technology, applied in the direction of instruments, measuring electrical variables, measuring current/voltage, etc., can solve the problems of non-sensing, small sensing range, and wrong judgment of three-phase electricity, so as to eliminate damage or replace and improve Sensing judgment effect, effect of increasing sensing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

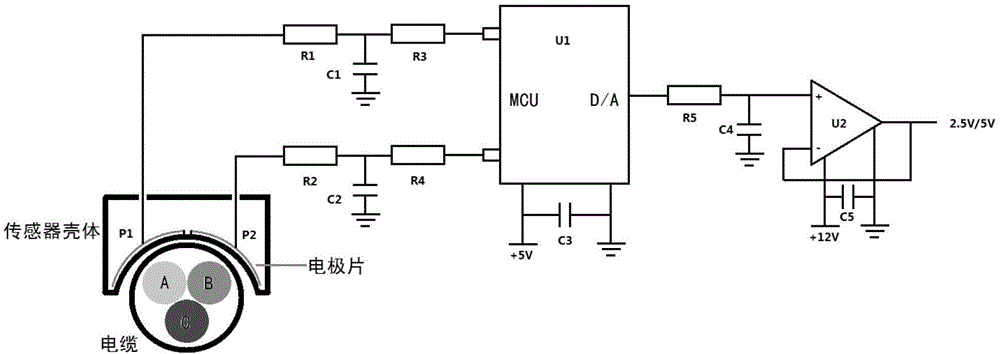

[0023] Such as figure 1 As shown, a non-contact power failure sensor includes a first electrode sheet P1 and a second electrode sheet P1 made of copper foil, both of the first electrode sheet P1 and the second electrode sheet P1 are in the shape of an arc surface , so that more electric field change signals can be collected during the detection of the alternating electric field of the cable to be tested.

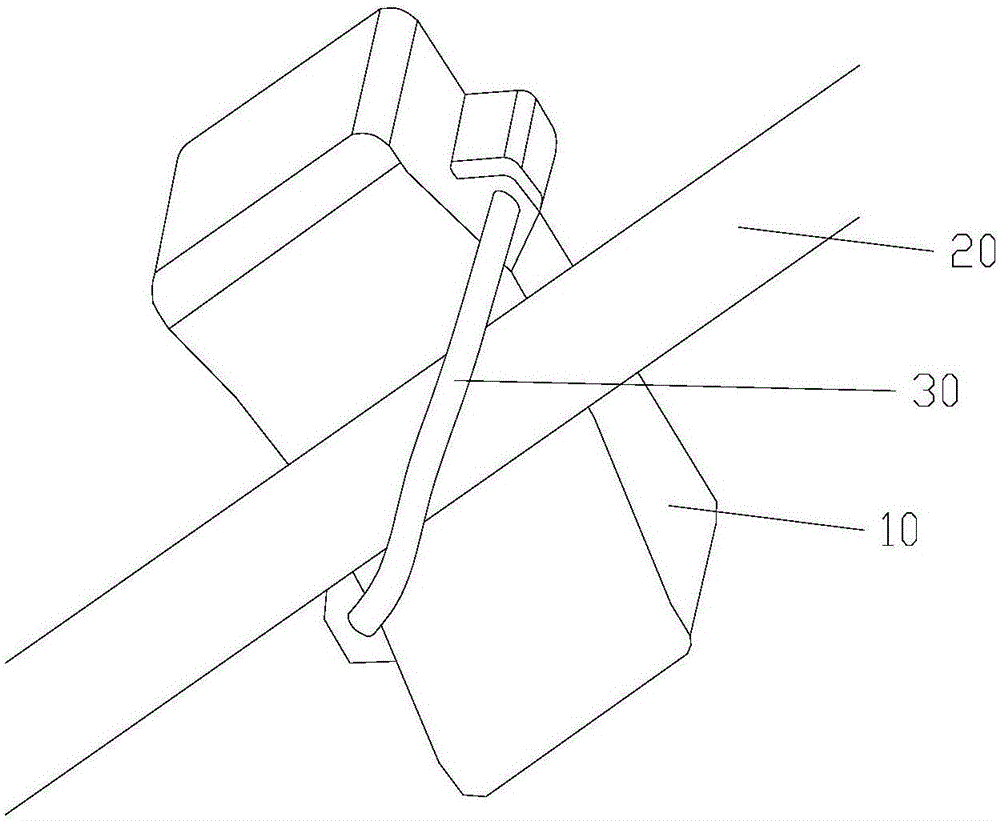

[0024] Such as figure 1 and figure 2 As shown, in order to facilitate the detection of the first electrode piece P1 and the second electrode piece P1, this embodiment also provides a sensor housing 10, at least one side wall of the sensor housing 10 is in the shape of an arc surface, so as to facilitate The sensor housing 10 is fixed to the cable 20 to be tested through the arc-shaped side wall, and the first electrode sheet P1 and the second electrode sheet P1 are attached to the arc-shaped side wall respectively. inside.

[0025] Such as figure 2 As shown, in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com