Vickers microhardness tester infinite imaging system and binocular microhardness tester

A technology of micro-hardness and imaging system, applied in the field of hardness tester, can solve the problems such as strict requirements on the size of objective lens and eyepiece parts, affecting the imaging quality and imaging effect of the system, and achieve ergonomic design, reduce component size, The effect of reducing the turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

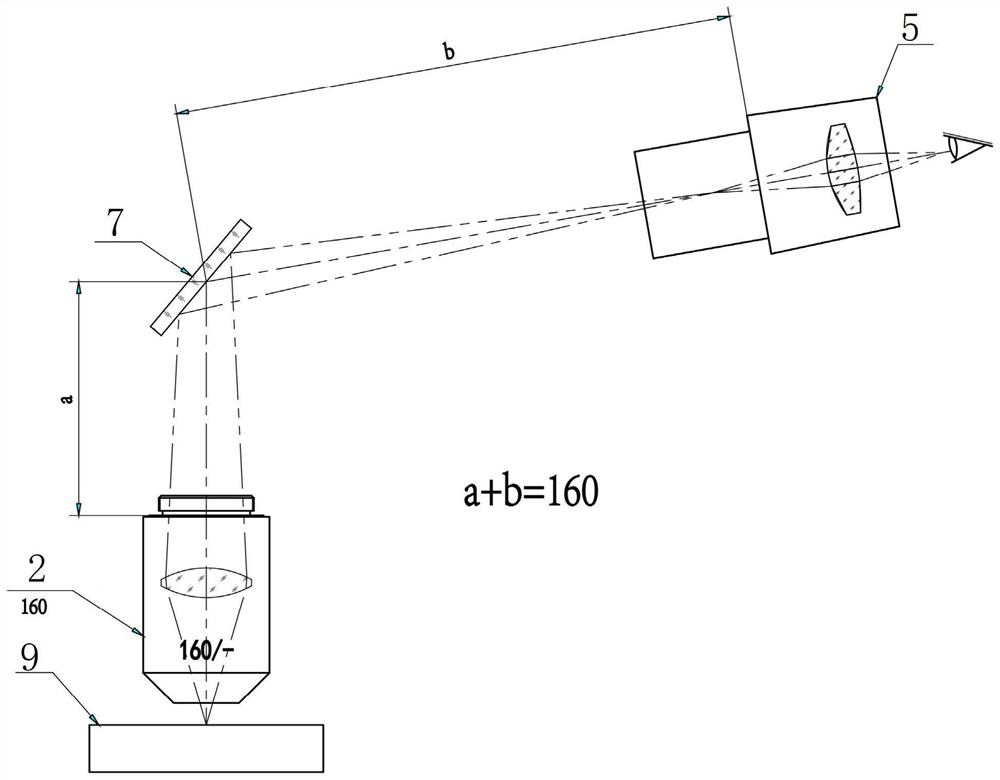

[0027] figure 2 It is the imaging system of the traditional desktop microhardness tester, that is, the finite distance imaging system. The finite distance imaging system adopts the finite distance imaging objective lens 2, and the output of the objective lens 2 is converging light, and the converging image plane must meet the standard parameters. That is, the distance a from the finite-distance objective lens 2 to the reflector 7 and the distance b from the reflector 7 to the eyepiece 5 in the figure must satisfy a+b=160mm in order to obtain a normal imaging effect.

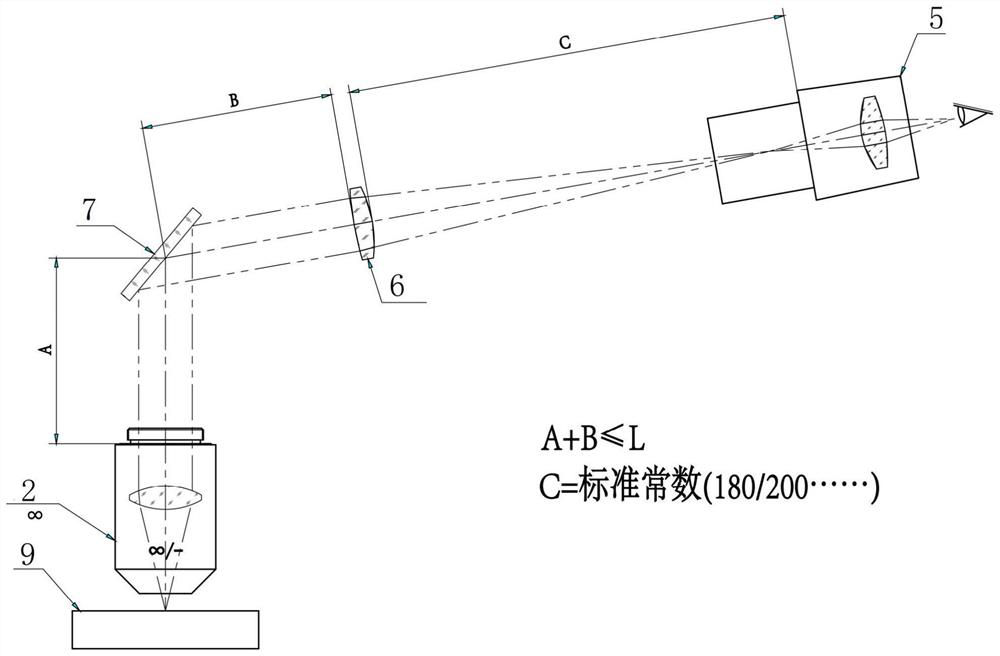

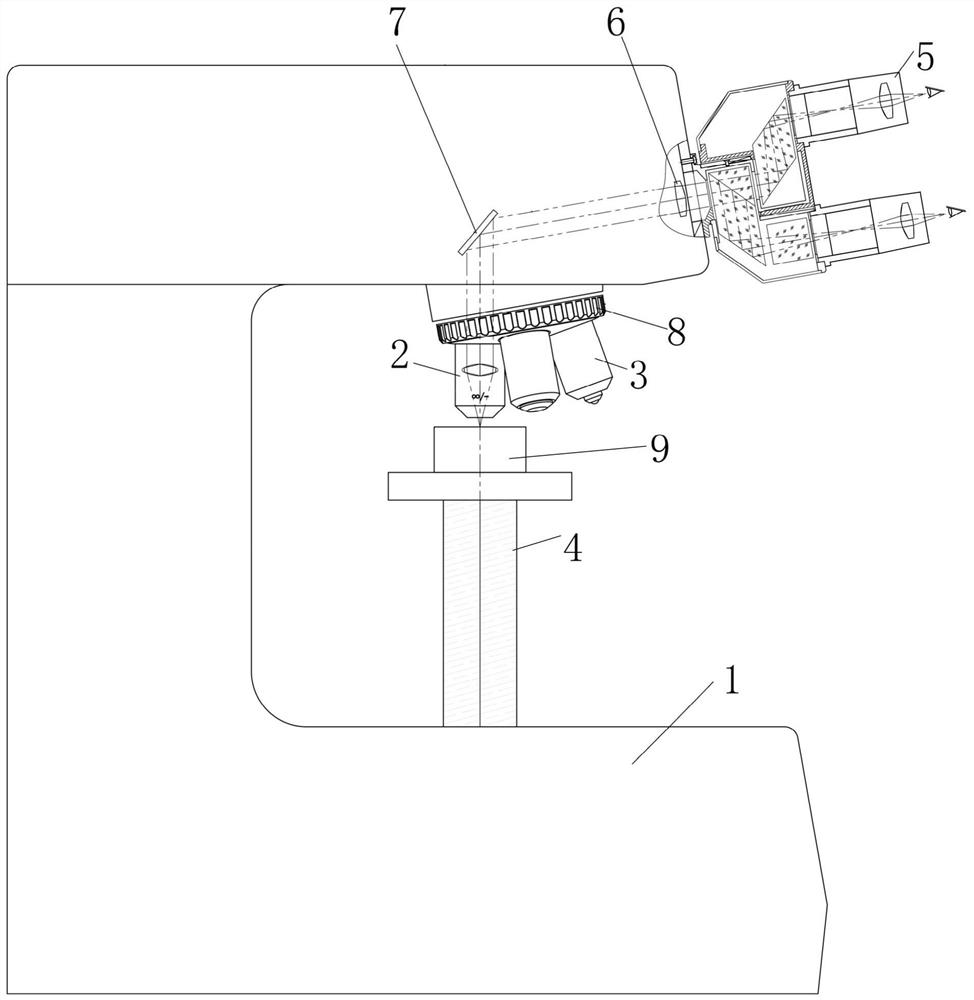

[0028] figure 1 It is a new type of Vickers microhardness tester infinity imaging system, which includes amplifying imaging device, independent hardness indenter, converter device, reflection device, infinity auxiliary optical system imaging device, and observation tube device along the optical path from bottom to top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com