Subframe fatigue test bending moment, torque elimination device

A fatigue test, sub-frame technology, applied in the direction of measuring device, vehicle test, mechanical component test, etc., can solve problems such as damage to the drive shaft, high cost, damage to the sensor, etc., to avoid installation distance, reduce installation difficulty, Accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

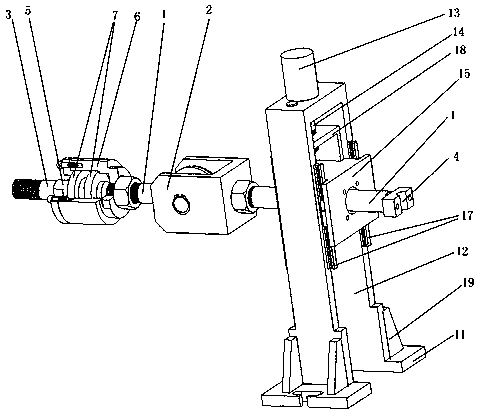

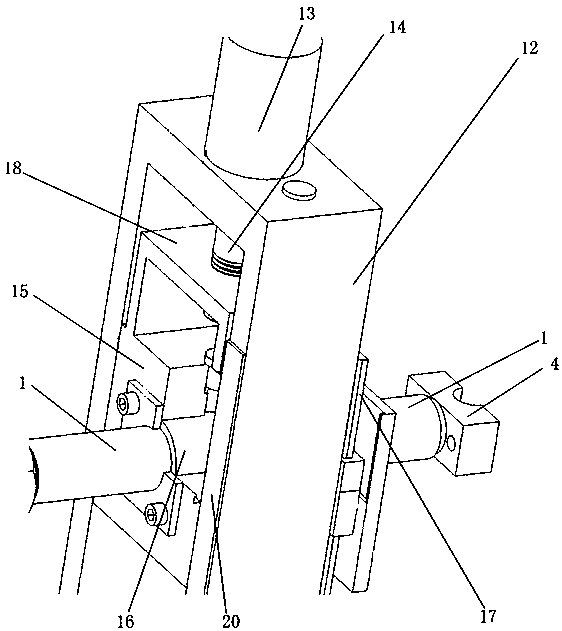

[0030] like Figure 1-3 As shown, the subframe fatigue test bending moment and torque elimination device provided in this embodiment include a main shaft 1, a height adjustment device, a universal joint 2, a transmission shaft 3, and a torque elimination device;

[0031] The main shaft 1 is installed on the height adjustment device, and can move up and down in the vertical direction under the action of the height adjustment device;

[0032] The two ends of the main shaft 1 are divided into two sides located on the height adjustment device, the front end of the main shaft 1 is provided with a universal joint 2, and the rear end of the main shaft 1 is provided with a workpiece connection part 4;

[0033] The torque elimination device is connected with the universal joint 2 through the main shaft 1, and the other end of the torque elimination device is connected with the transmission shaft 3;

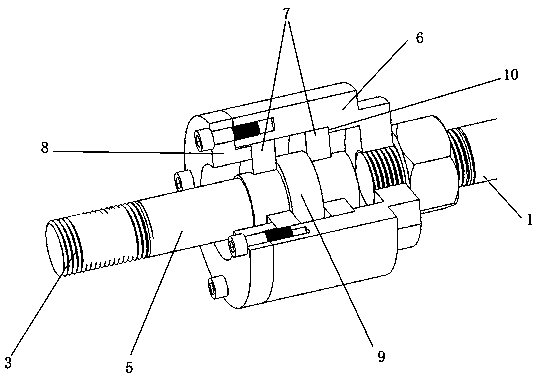

[0034] The torque elimination device includes a shaft 5, a sleeve 6, a tapered roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com